Gradient multiferroic material and preparation method thereof

A technology of multiferroic materials and ferroelectric materials, applied in the field of gradient multiferroic materials, can solve problems such as fatigue, easy falling off, pollution, etc., achieve strong magnetoelectric coupling effect, strong high temperature stability, and solve the effects of easy delamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

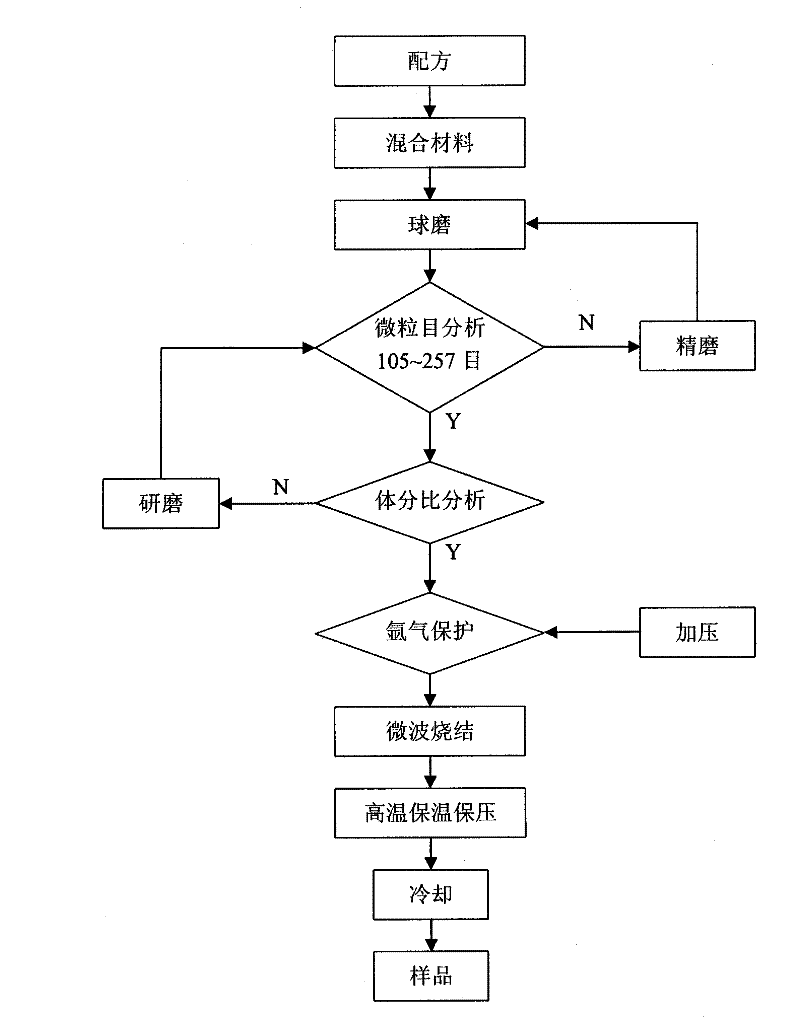

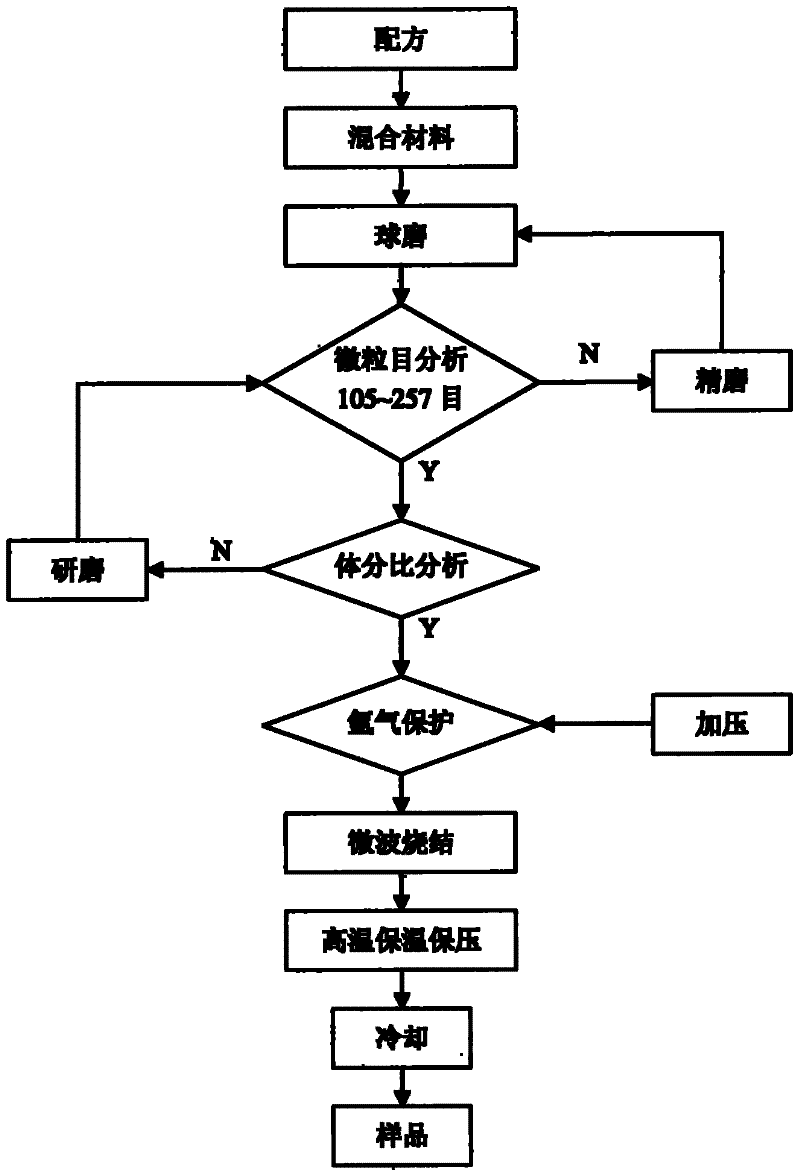

Method used

Image

Examples

Embodiment 1

[0012] Nb-SrTiO 3 and Ni 2 MnGa is mixed according to the ratio of 12% and 79%, and then add 9% BaTiO 3 , through ball milling to 105-232 mesh, of which 135-201 mesh accounts for 55%; after mixing evenly, at 1570kg / cm 2 Under pressure, press into an embryo body, in an argon protective atmosphere, microwave sintering for 1.5 hours, heat to 1480°C, keep warm for 3 hours, and take out the sample after cooling. The magnetoelectric effect of the material was measured by the resonant cavity perturbation method, and the ferroelectricity, ferromagnetism and carrying capacity were evaluated by referring to relevant standards.

[0013] After testing, the bearing characteristics of the gradient multiferroic material are as follows: the coefficient of thermal expansion at high temperature is 2.3×10 -6 / ℃, the high temperature flexural strength is 9.7MPa, and the dielectric constant is 8.2.

Embodiment 2

[0015] Nb-SrTiO 3 and Ni 2 MnGa is mixed according to the ratio of 61% and 32%, and 7% BaTiO is added 3 , through ball milling to 121-257 meshes, of which 136-231 meshes accounted for 55%. After mixing evenly, in an argon protective atmosphere, at 1420kg / cm 2 Under pressure, after microwave sintering for 1.5 hours, it was heated to 1610° C., kept for 3 hours, and the sample was taken out after cooling. The magnetoelectric effect of the material was measured by the resonant cavity perturbation method, and the ferroelectricity, ferromagnetism and carrying capacity were evaluated by referring to relevant standards.

[0016] After testing, the bearing capacity of the gradient multiferroic material is as follows: the coefficient of thermal expansion at high temperature is 1.9×10 -6 / °C, the high temperature flexural strength is 10.9MPa, and the dielectric constant is 7.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com