Embedded capacitance type liquid crystal touch screen

A technology with built-in capacitance and touch screen, which is applied in the input/output process of electrical digital data processing, instruments, and data processing, etc., and can solve the problems of decreased light transmittance, non-compliance with displays, and increased thickness and weight of touch panels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

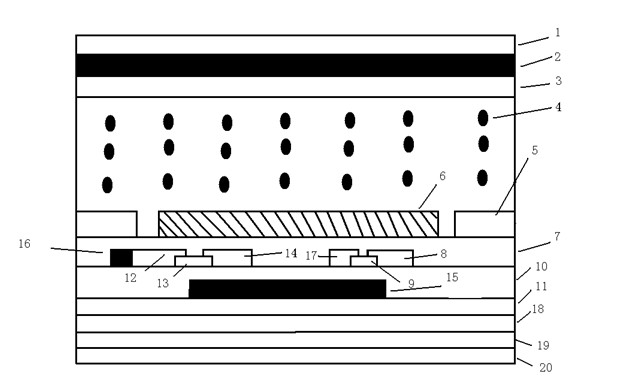

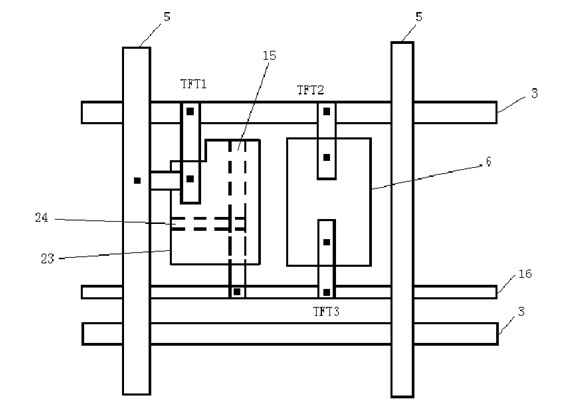

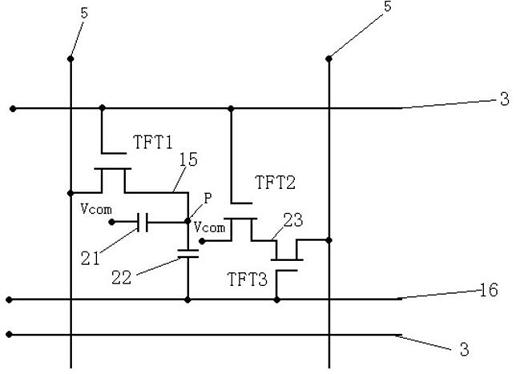

[0010] Control attached figure 1 , embedded capacitive liquid crystal touch screen, including a first transparent glass substrate layer 1, a second transparent glass substrate layer 11, a first indium tin oxide ITO layer 3, a second indium tin oxide ITO layer 5, and a color filter layer 2. Liquid crystal layer 4, TFT active matrix layer 18, backlight module 20, polarizer layer 19, planarization layer 7, passivation layer 10; wherein, the color filter layer 2 is attached to the first transparent glass substrate layer 1, the first indium tin oxide ITO layer 3 is attached to the lower part of the color filter, the pixel electrode layer 6 is on the same plane as the second indium tin oxide ITO layer 5, and the liquid crystal layer 4 is located on the color filter layer 2 and the first pixel electrode layer 6, the lower part of the first pixel electrode layer 6 is a planarization layer 7, a passivation layer 10, a second glass substrate layer 11, a TFT active matrix layer 18, a pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com