Flyback power converter

A power converter and flyback technology, which is applied in the direction of output power conversion device, AC power input conversion to DC power output, electrical components, etc., can solve the problem of reducing the size and manufacturing cost of flyback power converters, Does not eliminate the problems of optocoupler and secondary feedback circuit, increase manufacturing cost, etc., achieves the effect of shortening the design cycle, reducing external components, and simplifying the structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the object, technical solution and advantages of the present invention more clearly, the present invention will be further described in detail below in conjunction with specific examples.

[0036] At first, the technical term of the present invention is explained:

[0037] MOSFET: Metal Oxide Semiconductor FET, Metal Oxide Semiconductor Field Effect Transistor;

[0038] PWM: Pulse Width Modulation, pulse width modulation;

[0039] PFM: Pulse Frequency Modulation, pulse frequency modulation;

[0040] DCM: Discontinuous Conduction Mode, discontinuous (discontinuous) conduction mode;

[0041] CCM: Continuous Conduction Mode, continuous conduction mode.

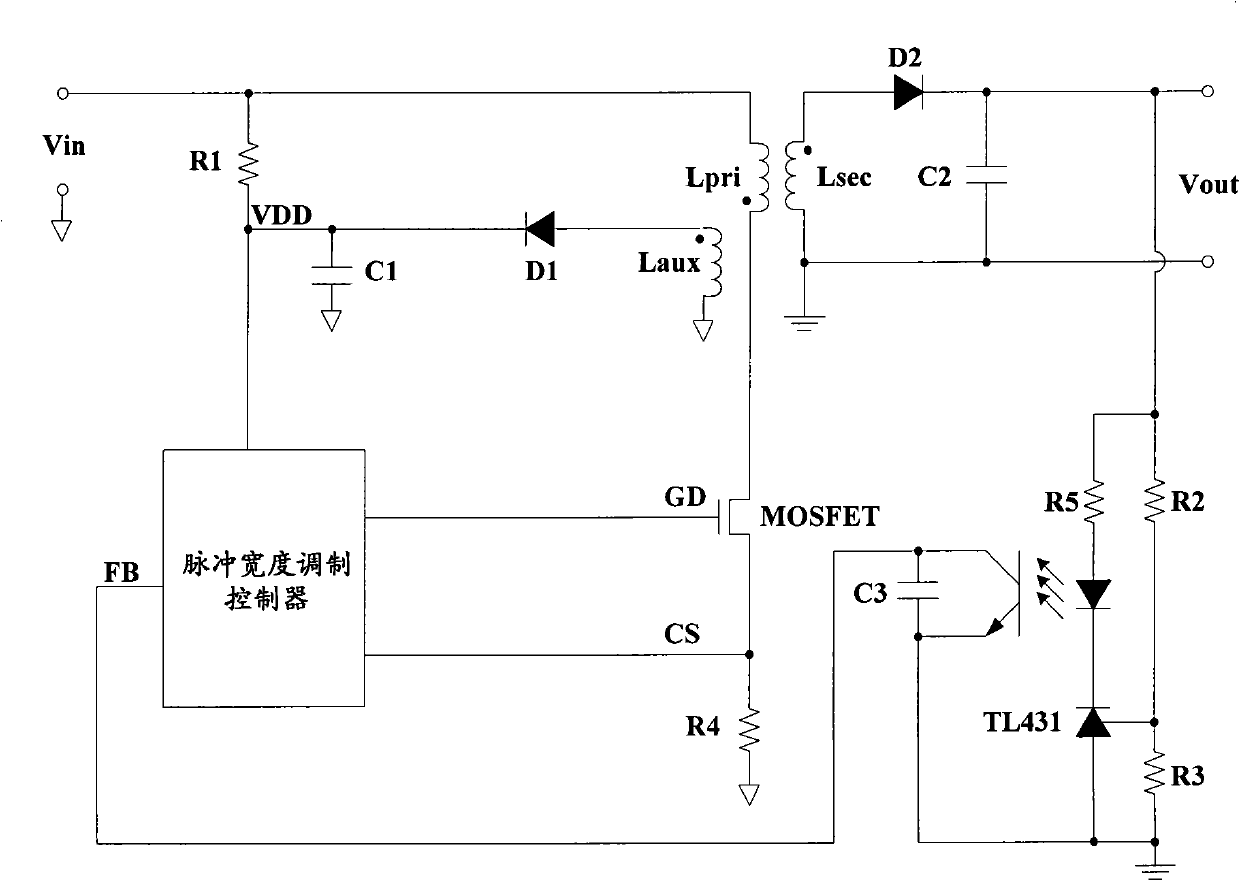

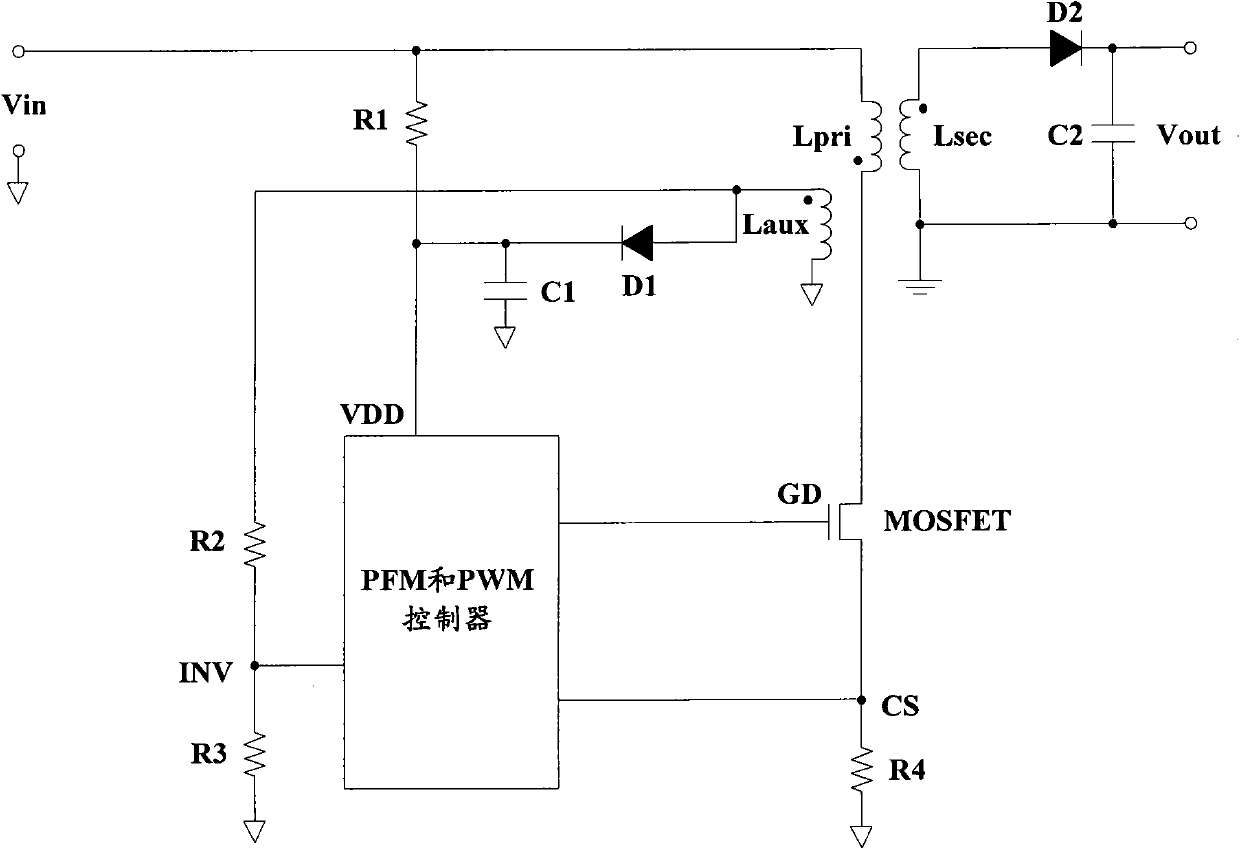

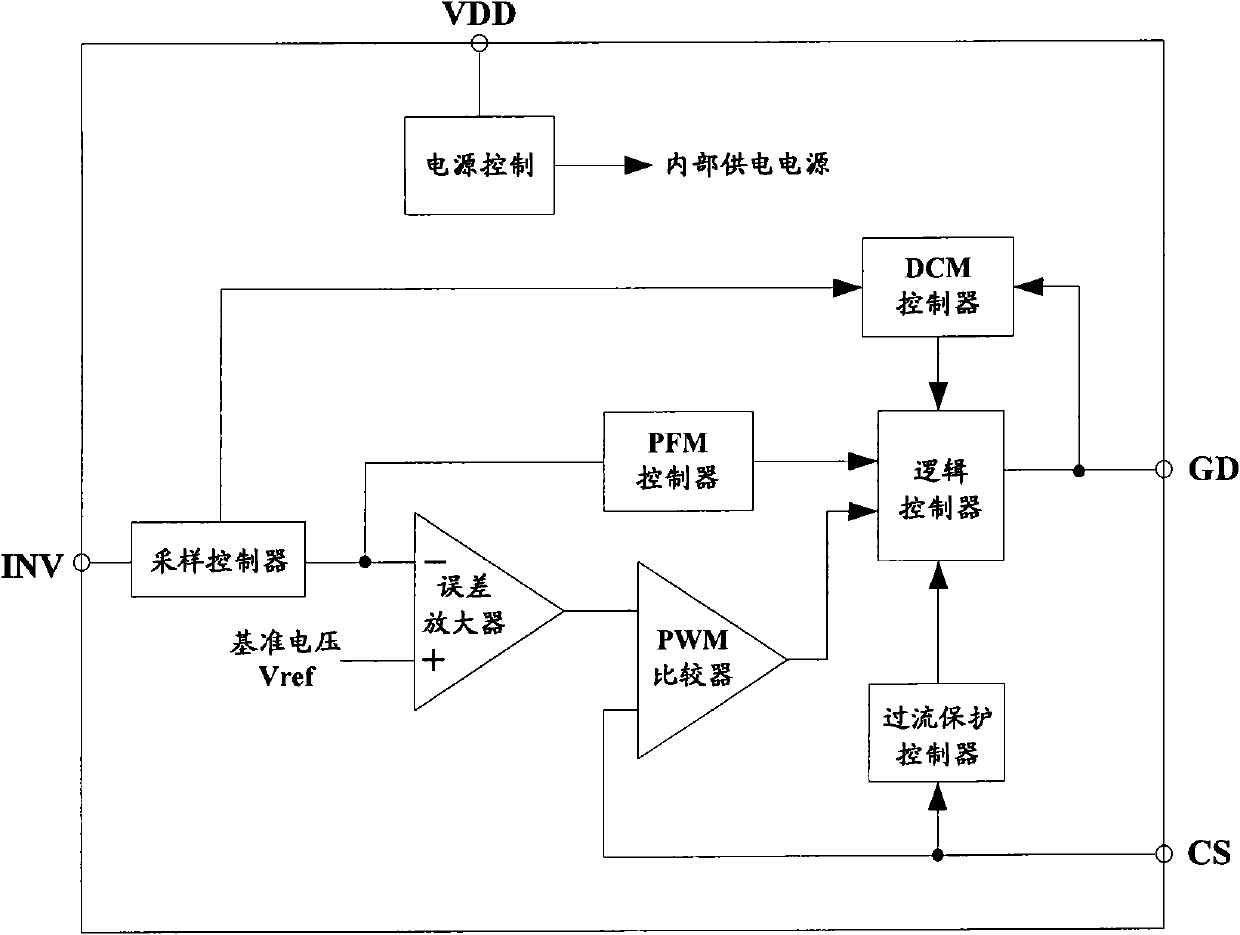

[0042] Such as figure 2 As shown, it is a schematic circuit diagram of a flyback power converter in an embodiment of the present invention. The flyback power converter includes: a transformer, a first rectifier D1, a second rectifier D2, a first capacitor C1, a second Capacitor C2, first resistor R1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com