Cylindrical battery

A technology for cylindrical batteries and pole groups, which is applied in secondary batteries, battery components, secondary battery manufacturing, etc., and can solve the problem of high current charging and discharging performance, battery heat dissipation performance needs to be improved, and tabs or connectors are hot and red. , Large-capacity battery heat dissipation difficulties and other issues, to achieve excellent high-current charge and discharge performance and safety performance, improve internal heat dissipation performance, and improve the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

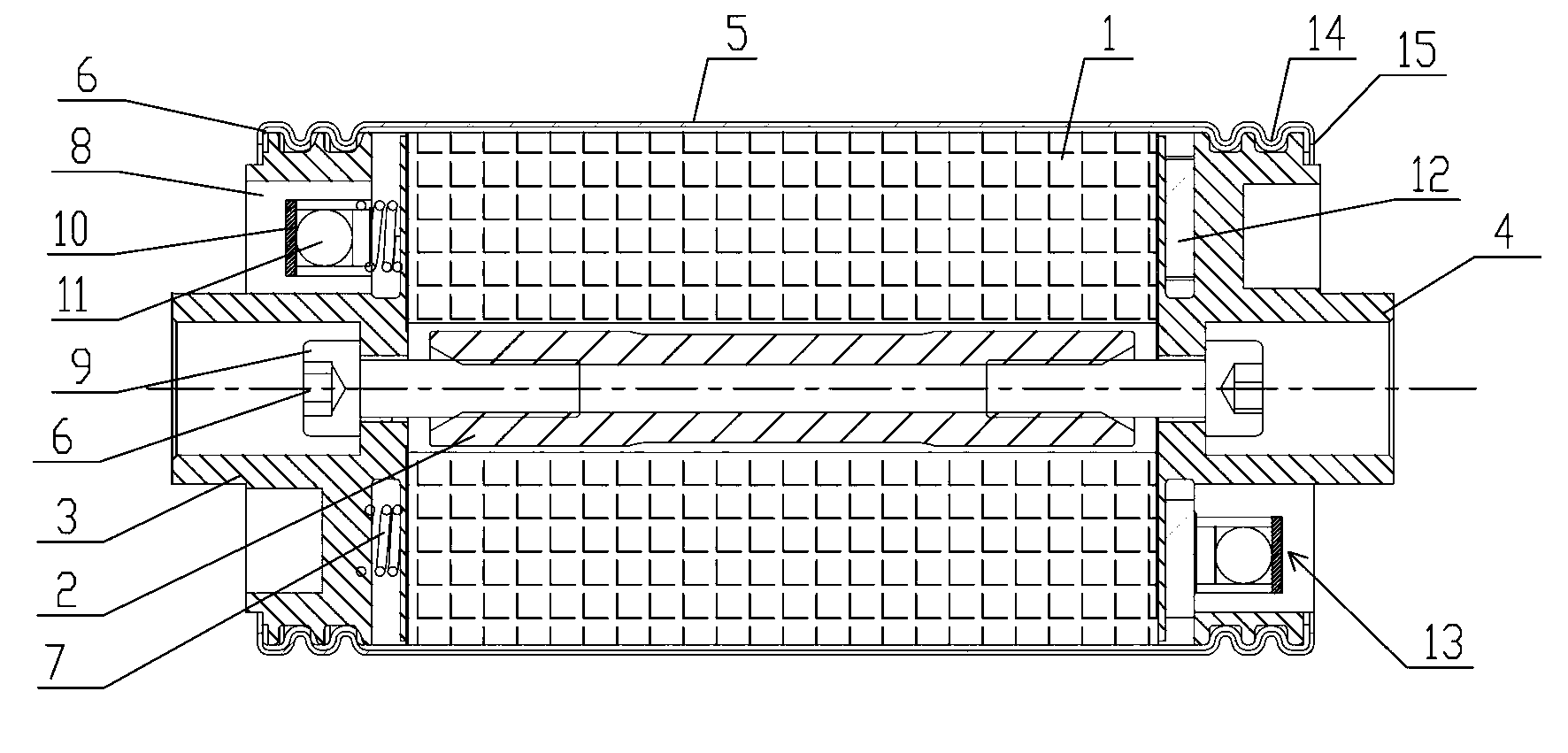

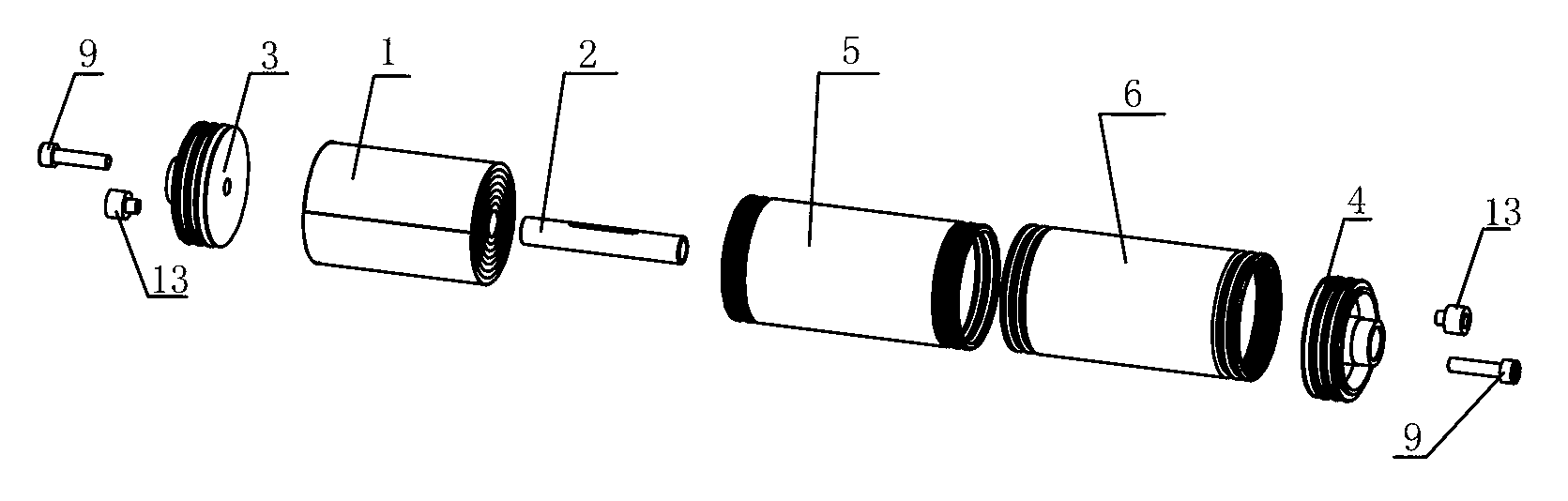

[0018] Such as figure 1 with figure 2 As shown, the cylindrical battery of the present invention includes a cylindrical battery electrode group 1 wound from a positive electrode sheet and a negative electrode sheet separated by a separator, and the cylindrical battery electrode group 1 is wound on a mandrel 2; The cylindrical battery pole group 1 is installed in the casing 5, and the casing 5 is lined with an insulating rubber sleeve 6; The entire end of the positive electrode sheet at the opposite end is connected, and the inner end surface of the negative electrode lead-out end 4 at the other end of the cylindrical battery electrode group 1 is directly connected to the entire end of the negative electrode sheet at the opposite end of the cylindrical battery electrode group 1, thereby Consisting of a non-welded surface contact confluence structure with the positive terminal and the negative terminal respectively arranged at both ends of the battery.

[0019] see figure 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com