Non-contact temperature-measuring electric cooker and temperature measuring method

A non-contact, rice cooker technology, applied in the direction of thermometers, thermometers, measuring devices, etc., which use electrical/magnetic components directly sensitive to heat, can solve the problems of temperature sensor contact, easy failure, and high cost, and achieve accurate and easy measurement. effect achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

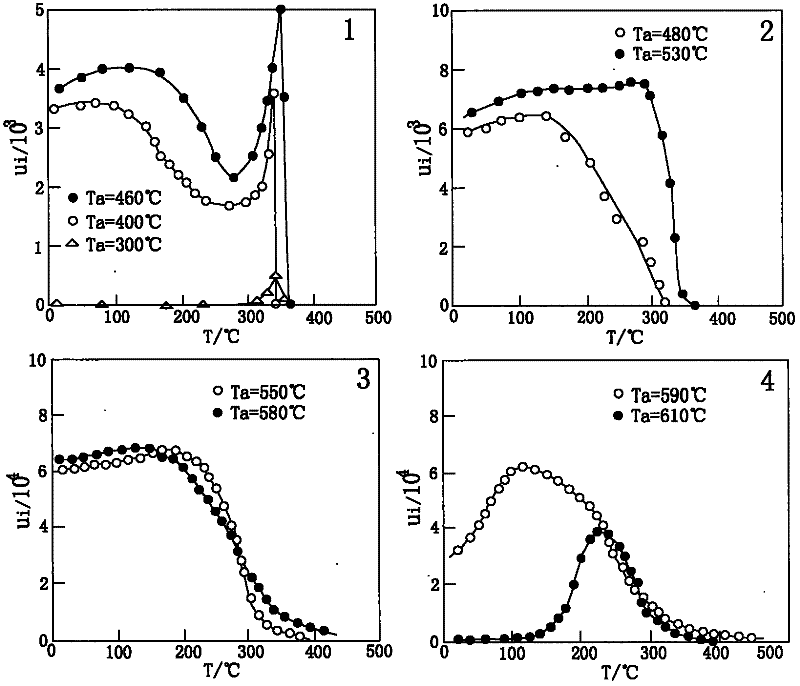

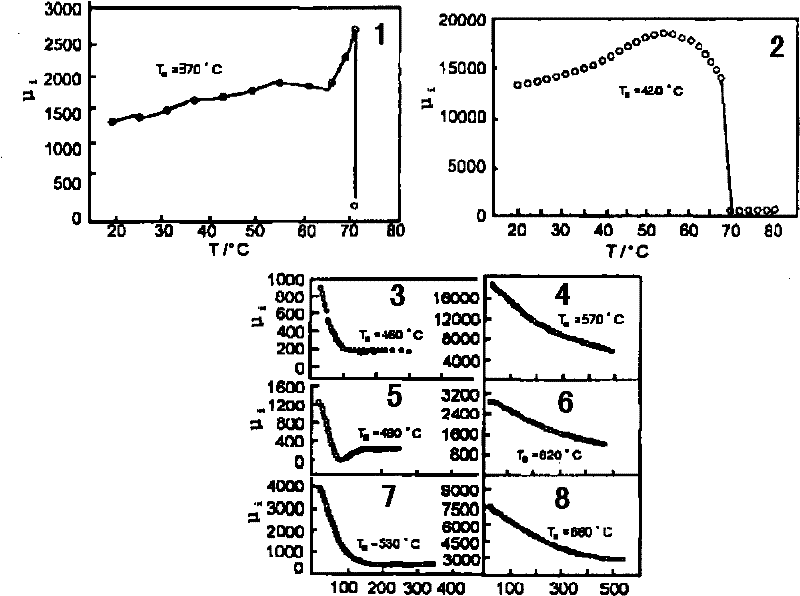

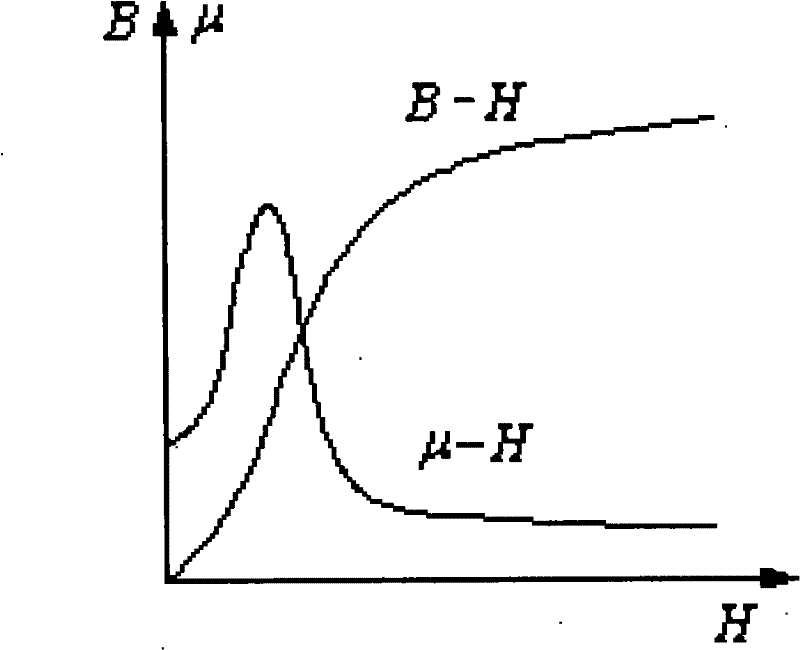

[0082] Such as Figure 10 , 11 As shown, the electric rice cooker described in this embodiment is an ordinary electric rice cooker. In the outer shell 1 of the electric rice cooker, an inner shell 3, an inner pot 9, and a heating plate 4 are included. The electric heating tube is embedded in the heating plate. A magnetic temperature-sensing element 10 that is always in contact with the inner pot 9 is arranged at the bottom, and a temperature-measuring induction coil 6 is arranged in the center of the heating plate 4 at the corresponding position of the magnetic temperature-sensing element 10, which is referred to in this embodiment as The temperature-measuring induction coil, an excitation coil 2, and the corresponding control circuit 8, the temperature-measuring induction coil and the thermistor 7 are fixed below the bottom of the inner shell 3 by the bracket 5, and the magnetic temperature-sensing element 10 is fixed in the middle of the inner shell 3 upper surface of the b...

Embodiment 2

[0088] The rice cooker in Embodiment 1 is an ordinary rice cooker, not an electromagnetic rice cooker. This embodiment is an electromagnetic rice cooker. The heating plate 4 is an electromagnetic heating coil, and the magnetic temperature sensing element 10 is installed at the bottom of the inner pot 9 and the bottom of the inner shell 3. An excitation coil 2 is arranged on the surface, or the electromagnetic heating coil is used as the excitation coil at the same time, that is, the electromagnetic heating coil is also used as a magnetic temperature sensing element 10 and temperature measurement while applying an alternating magnetic field to heat the inner pot made of ferromagnetic material. The excitation coil of the induction coil 6, the inner pot 9 is made of ferromagnetic material, the size, shape and quality of the inner pot, the size, shape and quality of the magnetic temperature sensing element, and various parameters between the temperature measurement induction coils a...

Embodiment 3

[0093] Others are the same as the second embodiment, the difference is that since the magnetic temperature sensing element 10 in the second embodiment is arranged in the middle of the heating plate 4, in order to avoid or reduce the influence of the electromagnetic heating coil on the magnetic temperature sensing element 10 and the temperature sensing coil 6 A high-permeability ferromagnetic shielding ring can be arranged between the electromagnetic heating coil and the temperature-measuring induction coil 6 , and at the same time, this method can also reduce the influence of the electromagnetic heating coil on the magnetic temperature-sensing element 10 . Specifically, methods of prior art can be used, for example: "Difficulties in electromagnetic shielding-magnetic field shielding" (Electronic Quality 2006 No. 10) discloses low-frequency magnetic fields (referring to alternating magnetic fields below 100 kHz, while household electromagnetic rice cookers The working frequency ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com