Preparation method of modified pumice packing for purifying sewage

A sewage purification and modification technology, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of low TP removal rate and low total nitrogen removal rate, and reach the source Rich, good treatment effect, good purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

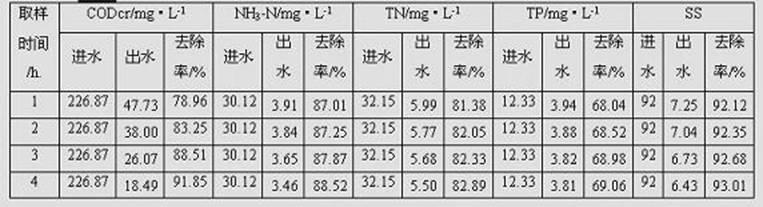

Embodiment 1

[0013] Select pumice, crush, sieve, and grind to obtain irregular particles (Φ=5-50 mm); then use imidazole-type ionic liquid-1-butyl-3-methylimidazole Chlorinated salt ([Bmin]Cl) soaking modification treatment at room temperature (final concentration of lanthanide rare earth elements is 0.05 mol / L, final concentration of ionic liquid is 0.01 mol / L, soaking time is 6 h.), drained to obtain the finished product .

Embodiment 2

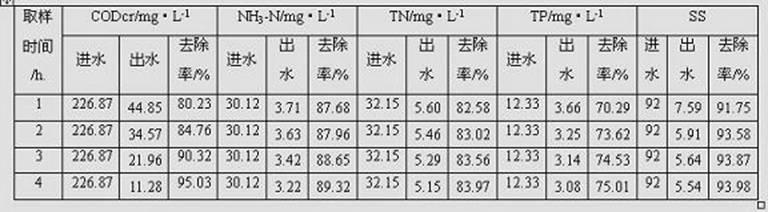

[0015] Select pumice, crush, sieve, and grind to obtain irregular particles (Φ=10-100 mm); then use pyridine-type ionic liquid-N-ethylpyridine bromide (N - ethylpyridinium bromide) soaked at room temperature for modification (the final concentration of lanthanide rare earth elements is 0.1 mol / L, the final concentration of ionic liquid is 0.005 mol / L, and the soaking time is 12 h.), drained to obtain the finished product.

Embodiment 3

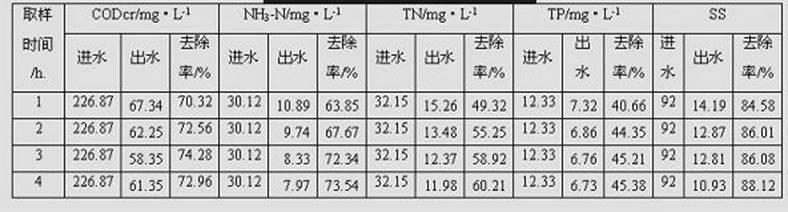

[0017] Select pumice, crush, sieve, and grind to obtain irregular particles (Φ=5-100 mm); then use piperidine imidazole type ionic liquid-bromide N-methyl, ethyl N-ethyl-methyl pipe was soaked and modified at room temperature (the final concentration of lanthanide rare earth elements was 0.001 mol / L, the final concentration of ionic liquid was 0.001 mol / L, and the soaking time was 24 h.), drained, Get the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com