Refuse incineration plant percolate treatment system

A treatment system and waste incineration technology, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. and other problems to achieve the effect of avoiding sludge loss, reducing the amount of concentrated liquid, and occupying a small area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

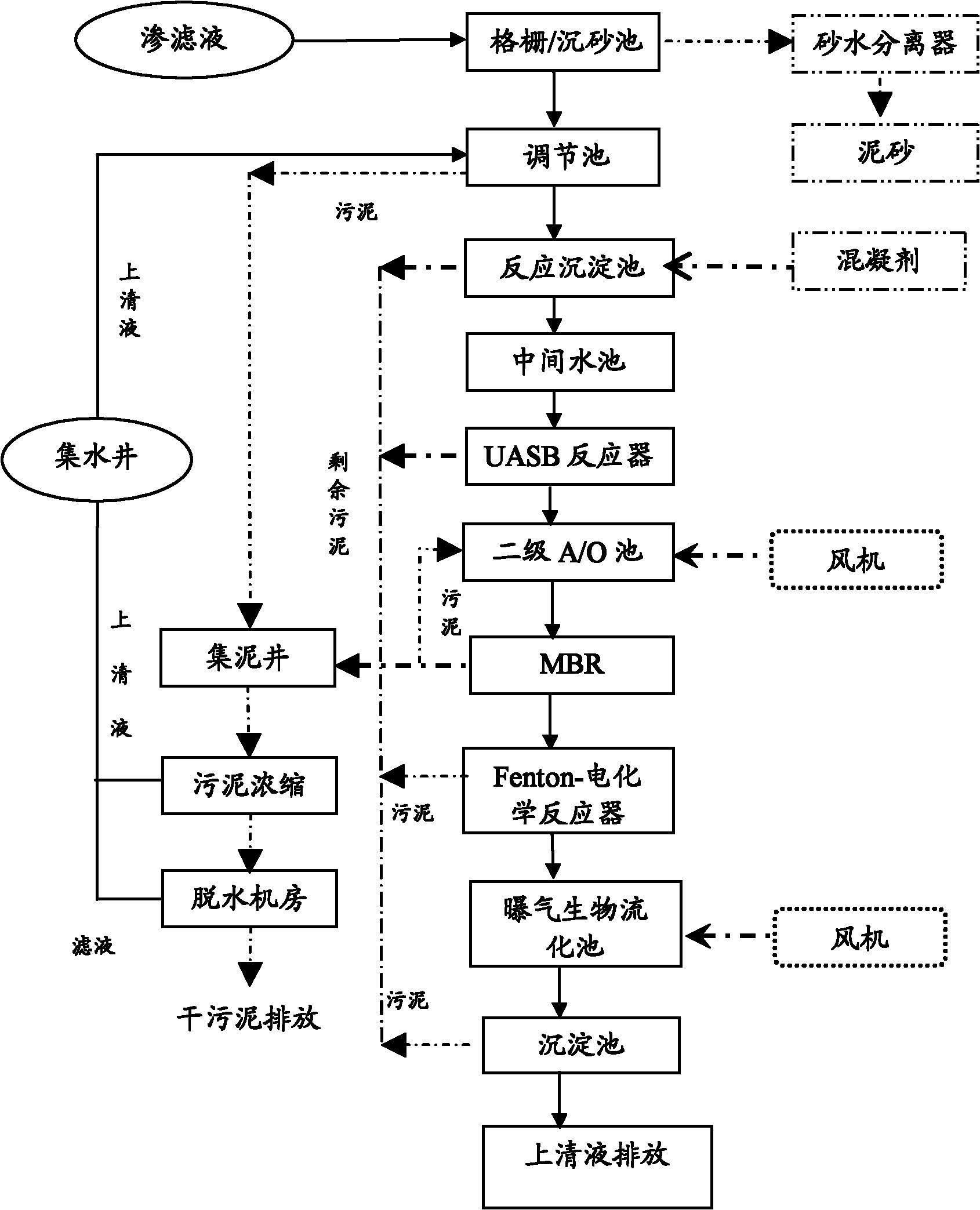

[0074] The present invention will be further described in detail below with reference to the drawings and embodiments.

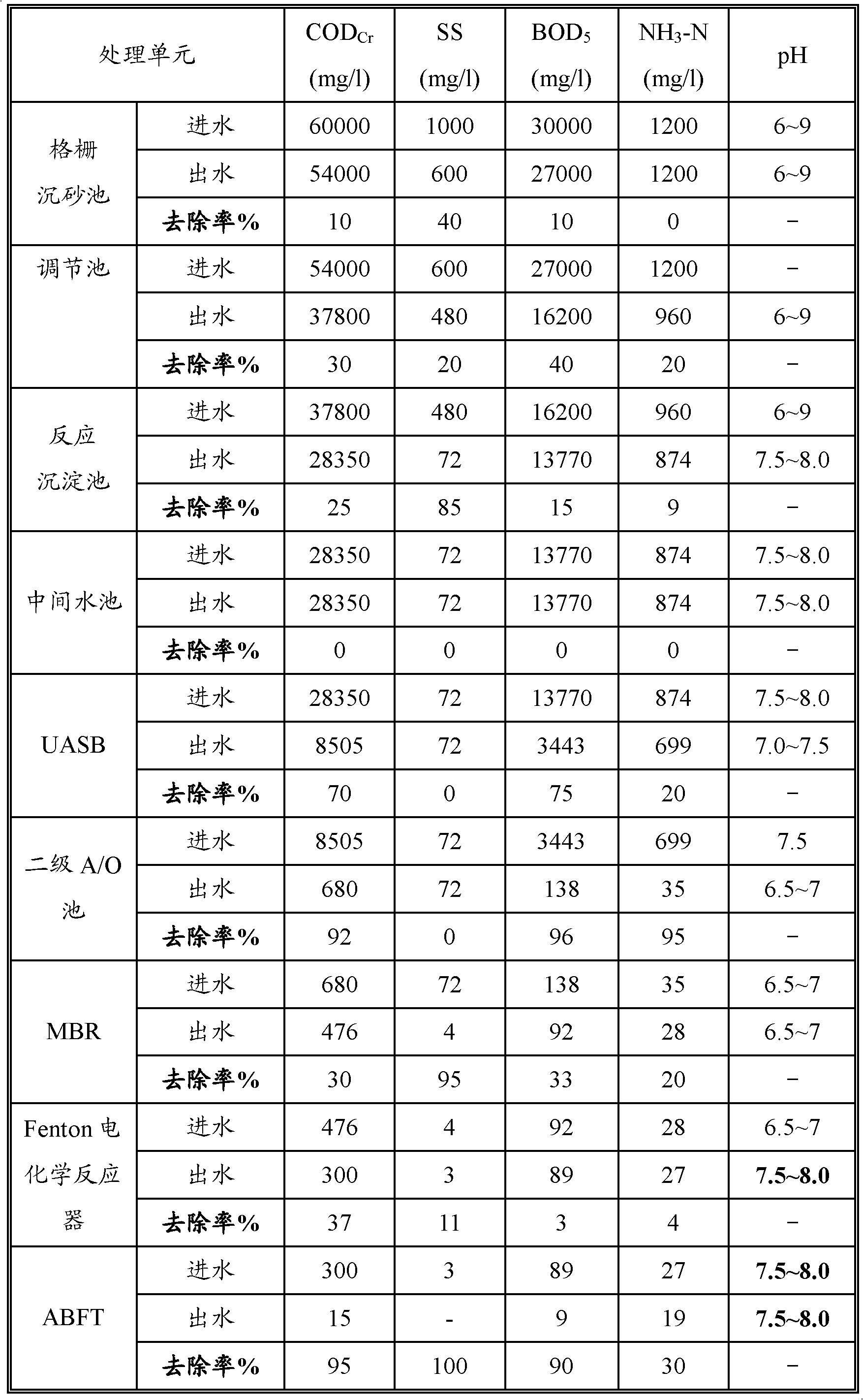

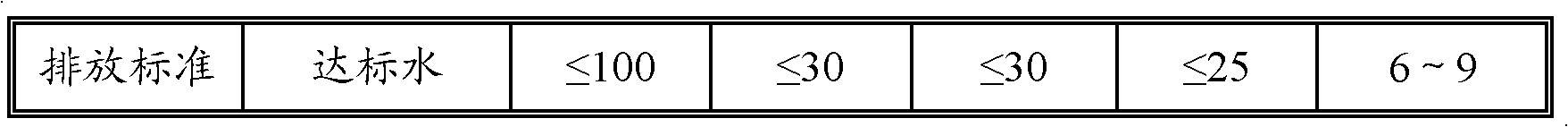

[0075] This embodiment mainly has the following 10 processing units, which are summarized as follows:

[0076] 1. Grid / grit tank

[0077] After collecting the landfill leachate through the pipeline, it enters the coarse and fine grids and grit tanks to remove larger suspended matter, floating matter, fibrous matter and other larger solid particulate matter, and the separated matter enters the sand-water separator. Separate mud and sand.

[0078] 2. Regulating pool

[0079] The leachate flows into the regulating tank to be adjusted after sand settling. In this embodiment, the main functions of the conditioning tank are: ①, adjust the water volume and uniform water quality, reduce the impact load on the subsequent treatment system; ②, have a certain hydrolytic acidification effect. The adjustment tank transfers the excess leachate to the mud collecting well, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com