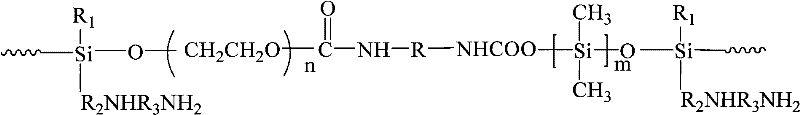

Polyether block amino silicone softening finishing agent, its preparation method and application

A softening finishing agent, polyether block technology, used in fiber treatment, textiles and papermaking, etc., can solve the problems of poor fabric washing performance, poor wettability and easy decontamination performance, etc., to reduce the greasy feel, reduce Adverse effects, good hydrophilic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Add 23.3g (0.007456mol) WS-62M, 114.6g (0.2865mol) polyethylene glycol 400 into the dry there-necked flask, pass N 2 Under air protection, the temperature of the water bath was raised to 65°C and stirred evenly, then 38.0g (0.2262mol) HDI was added dropwise thereto, and then the temperature was raised to 70°C, dibutyltin dilaurate catalyst was added dropwise, and the reaction was carried out at constant temperature for 2 hours. Then the temperature was raised to 90°C, 8.8g (0.0427mol) DL-602 and catalyst KOH were added to the reaction system, and the reaction was carried out at constant temperature for 5h. The temperature was lowered to 65°C, and an appropriate amount of acetic acid was added dropwise to the reaction system for neutralization until the pH was 6. Then lower the temperature to 20°C, slowly drop deionized water into the system to disperse, and then stir at constant temperature for 2 hours to obtain the polyether block amino silicone oil softening agent PEA...

Embodiment 2

[0049] Add 24.8g (0.007936mol) WS-62M, 122.5g (0.3062mol) polyethylene glycol 400 into the dry there-necked flask, pass N 2 Under air protection, heat the water bath to 65°C and stir evenly, then add 37.9g (0.2256mol) HDI dropwise thereto, then raise the temperature to 70°C, add dibutyltin dilaurate catalyst dropwise, and react at constant temperature for 1.5-2h. Then the temperature was raised to 95°C, 9.3g (0.045mol) DL-602 and catalyst KOH were added to the reaction system, and the reaction was carried out at constant temperature for 5h. The temperature was lowered to 65°C, and an appropriate amount of acetic acid was added dropwise to the reaction system for neutralization until the pH was 6. Then the temperature was lowered to 20°C, and deionized water was slowly added dropwise to the system, and then stirred at a constant temperature for 2 hours to obtain the polyether block amino silicone oil softening agent PEAS2.

Embodiment 3

[0051] Add 31g (0.00992mol) WS-62M, 125.3g (0.3132mol) polyethylene glycol 400 into the dry there-necked flask, pass N 2 Under gas protection, the temperature of the water bath was raised to 65°C and stirred evenly, then 36.2g (0.2155mol) HDI was added dropwise thereto, and then the temperature was raised to 75°C, dibutyltin dilaurate catalyst was added dropwise, and the reaction was carried out at constant temperature for 2h. Then the temperature was raised to 90°C, 9.6g (0.0466mol) DL-602 and catalyst KOH were added to the reaction system, and the reaction was carried out at constant temperature for 5h. The temperature was lowered to 65°C, and an appropriate amount of acetic acid was added dropwise to the reaction system for neutralization until the pH was 6. Then the temperature was lowered to 20°C, and deionized water was slowly added dropwise to the system, and then stirred at a constant temperature for 2 hours to obtain the polyether block amino silicone oil softening ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com