Battery insulation film

A technology of separator and battery, applied in battery pack parts, circuits, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

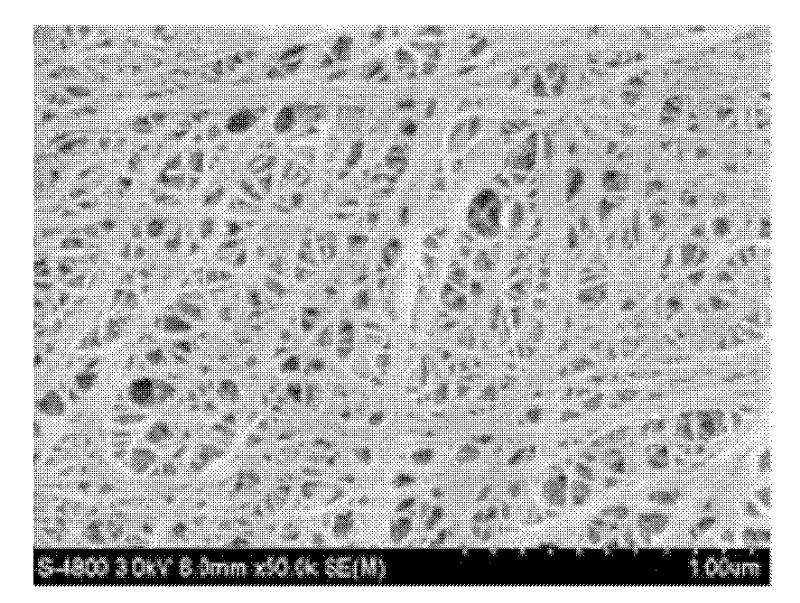

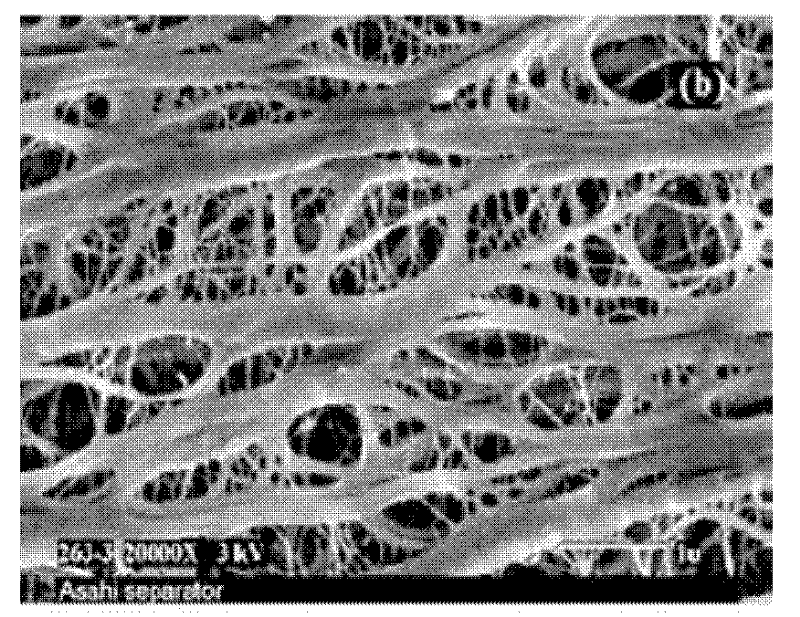

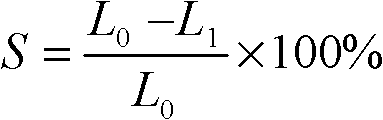

Image

Examples

Embodiment 1

[0087] Divide 120 grams to a density of 2×10 6 High-density polyethylene (purchased from PetroChina Lanzhou Petrochemical Company), 100 grams of molecular weight is 2 million ultra-high molecular weight polyethylene (purchased from PetroChina Lanzhou Petrochemical Company), 1 gram of antioxidant 2,6 tert-butyl-4-methyl Phenol and 2000 grams of mineral oil (CAS8020-83-5, purchased from Lanzhou Petrochemical Company) with a viscosity grade of No. 39 were added to the continuous batching feeder, stirred at a speed of 55 rpm, and the raw materials were mixed evenly.

[0088] The mixture is continuously added to the twin-screw extruder; under the condition of 120°C, the ultra-high molecular weight polyethylene and high-density polyethylene are continuously dissolved in the mixture of mineral oil and antioxidant in the twin-screw extruder, and then The twin-screw extruder is continuously extruded at a speed of 200 rpm; the mixture is continuously input into the slit die; the mixture...

Embodiment 2

[0093] Divide 220 grams to a density of 2×10 6High-density polyethylene (purchased from PetroChina Lanzhou Petrochemical Company), 100 grams of ultra-high molecular weight polyethylene (purchased from PetroChina Lanzhou Petrochemical Company) with a molecular weight of 8 million, 1.2 grams of antioxidant 2, 6 tert-butyl-4-methyl Phenol and 2200 grams of mineral oil (CAS8020-83-5, purchased from Lanzhou Petrochemical Company) with a viscosity grade of No. 39 were added to the continuous batching feeder, stirred at a speed of 50 rpm, and the raw materials were mixed evenly.

[0094] The mixture is continuously added to the twin-screw extruder; under the condition of 120°C, the ultra-high molecular weight polyethylene and high-density polyethylene are continuously dissolved in the mixture of mineral oil and antioxidant in the twin-screw extruder, and then The twin-screw extruder is continuously extruded at a speed of 200 rpm; the mixture is continuously input into the slit die; t...

Embodiment 3

[0098] Divide 520 grams to a density of 2×10 6 High-density polyethylene (purchased from PetroChina Lanzhou Petrochemical Company), 100 grams of molecular weight is 3 million ultra-high molecular weight polyethylene (purchased from PetroChina Lanzhou Petrochemical Company), 1.5 grams of antioxidant 2,6 tert-butyl-4-methyl Phenol and 3,500 grams of viscosity grade mineral oil (CAS8020-83-5, purchased from Lanzhou Petrochemical Company) were added into the continuous batching feeder, and stirred at a speed of 50 rpm to mix the raw materials evenly.

[0099] The mixture is continuously added to the twin-screw extruder; under the condition of 120°C, the ultra-high molecular weight polyethylene and high-density polyethylene are continuously dissolved in the mixture of mineral oil and antioxidant in the twin-screw extruder, and then The twin-screw extruder is continuously extruded at a speed of 200 rpm; the mixture is continuously input into the slit die; the mixture is extruded thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com