Liquid-solid fluidized bed microbial fuel cell hydrogen production device

A fuel cell and fluidized bed technology, which is applied in the field of electric-assisted hydrogen production in liquid-solid fluidized bed reactor biofuel cells, can solve the problems of low mass transfer efficiency, uneven distribution of microorganisms, and difficult industrial scale-up of sewage treatment, etc., to achieve High volume power density, accelerated biochemical reaction rate, improved effect and hydrogen production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

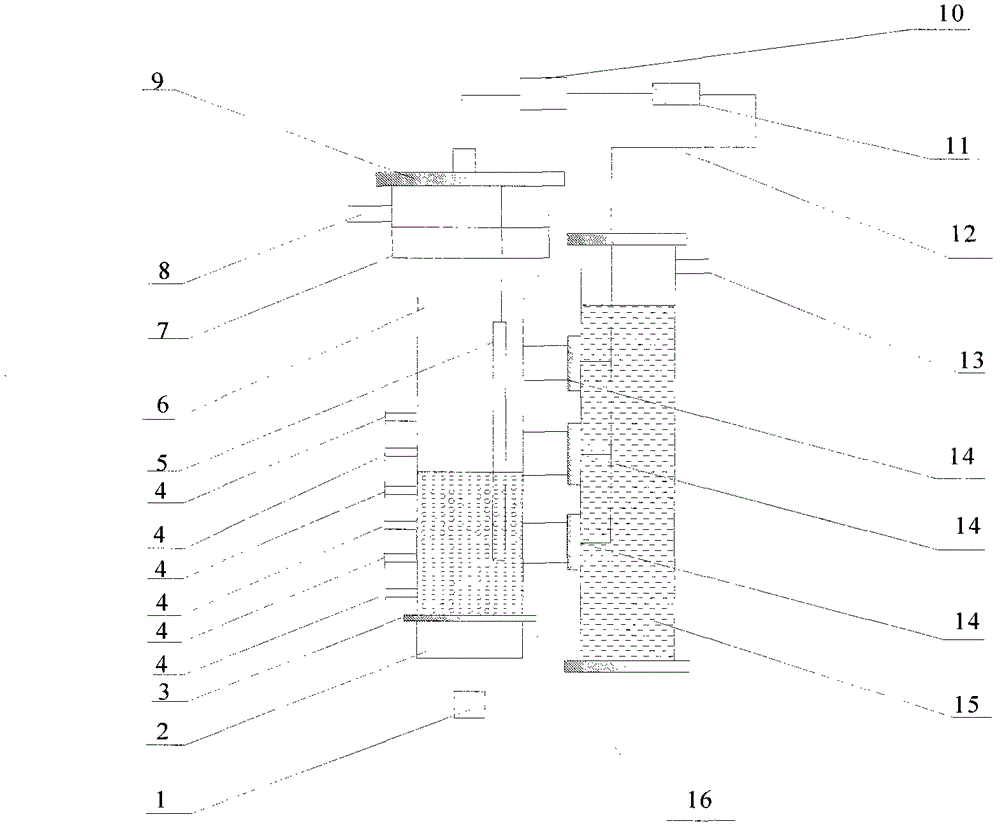

[0011] The main structure of this embodiment includes a sewage inlet 1, a pre-distribution chamber 2, a liquid distribution plate 3, a test port 4, an anode electrode 5, an anode fluidized bed body 6, a fluidized bed expansion section 7, a sewage outlet 8, and a sealing cover 9 , stabilized power supply 10, load 11, wire 12, gas collection outlet 13, cathode 14, cathode chamber 15 and fluidized particles 16, each component is combined to form an anaerobic fluidized bed membrane cathode microbial fuel cell device; sewage inlet 1 is located in the reaction The central position of the bottom of the device, the pipe diameter is Φ15mm; the sewage outlet 8 is located at the side wall of the anode fluidized bed body 6 50mm from the top, the pipe diameter is Φ15mm; the diameter of the pre-distribution chamber 2 is 40mm, and it is connected to the anode fluidized bed body 6 through the flange Connect; liquid distribution plate 3 opening diameter Φ1.5-2.5mm, opening ratio 10-15%, guarant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com