Quality control method for solder joint portion and quality control device

A technology for solder joints and quality management, which is applied in the direction of assembling printed circuits, electrical components, electrical components, etc., can solve the problem of soldering that is not suitable for mass production of multiple pins and narrow spacing, manual operation volatility, Problems such as low productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

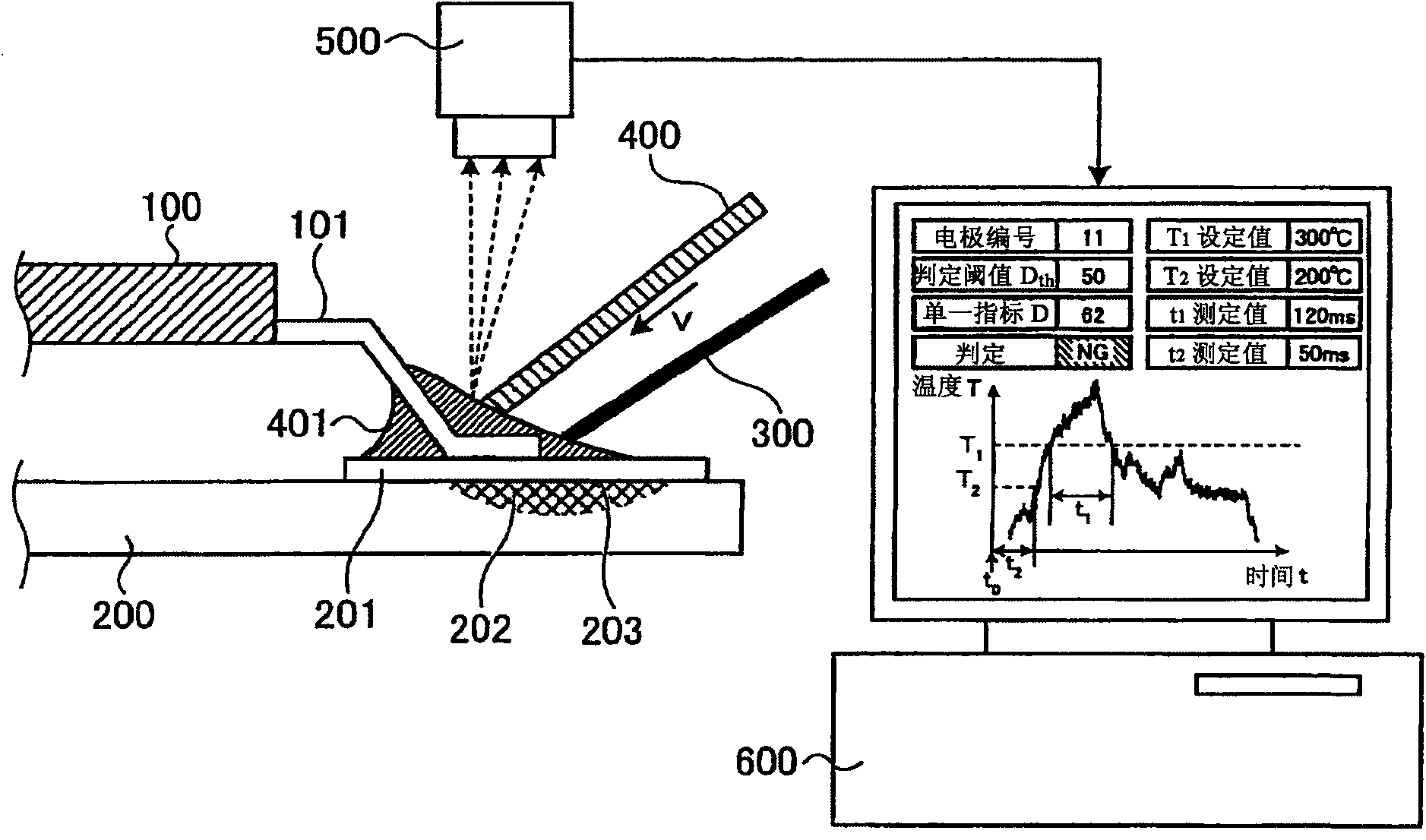

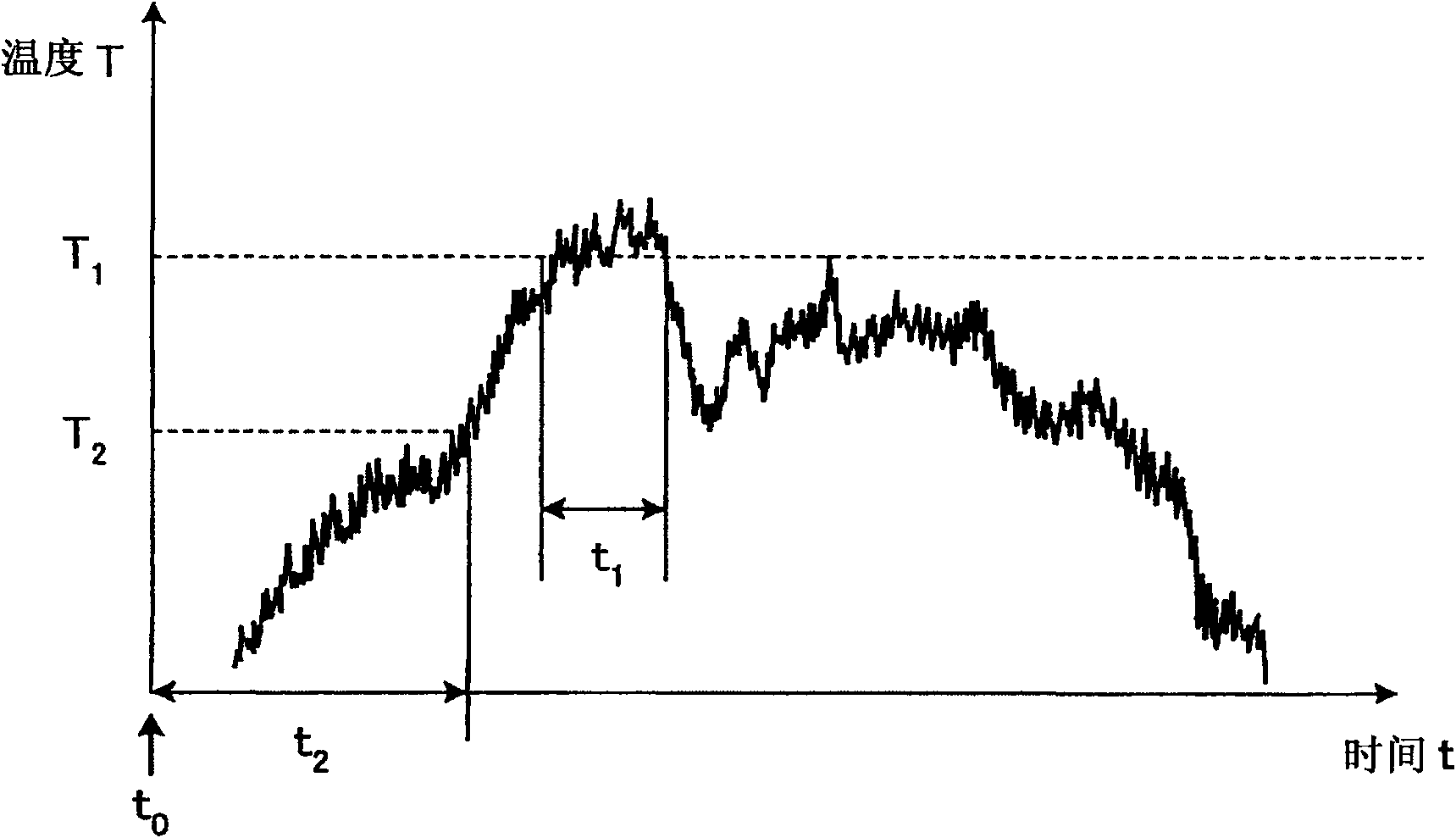

[0030] figure 1 It is a figure which shows the state in which the laser soldering of Embodiment 1 concerning this invention is joining. Component terminals 101 of electronic component 100 are bonded to substrate terminals 201 of resin substrate 200 via solder 401 . At a predetermined timing, a solid welding wire 400 (the feeding mechanism of the welding wire 400 is not shown) is supplied to the junction at a speed v (function of time), and at the same time, a laser beam 300 (laser beam 300) as a thermal energy supply source is supplied with a power p (function of time). Beam irradiation source, positioning mechanism, etc. are not shown in the figure). Such as figure 1 As shown, by locally supplying thermal energy, the temperature rise of the electronic component 100 can be suppressed.

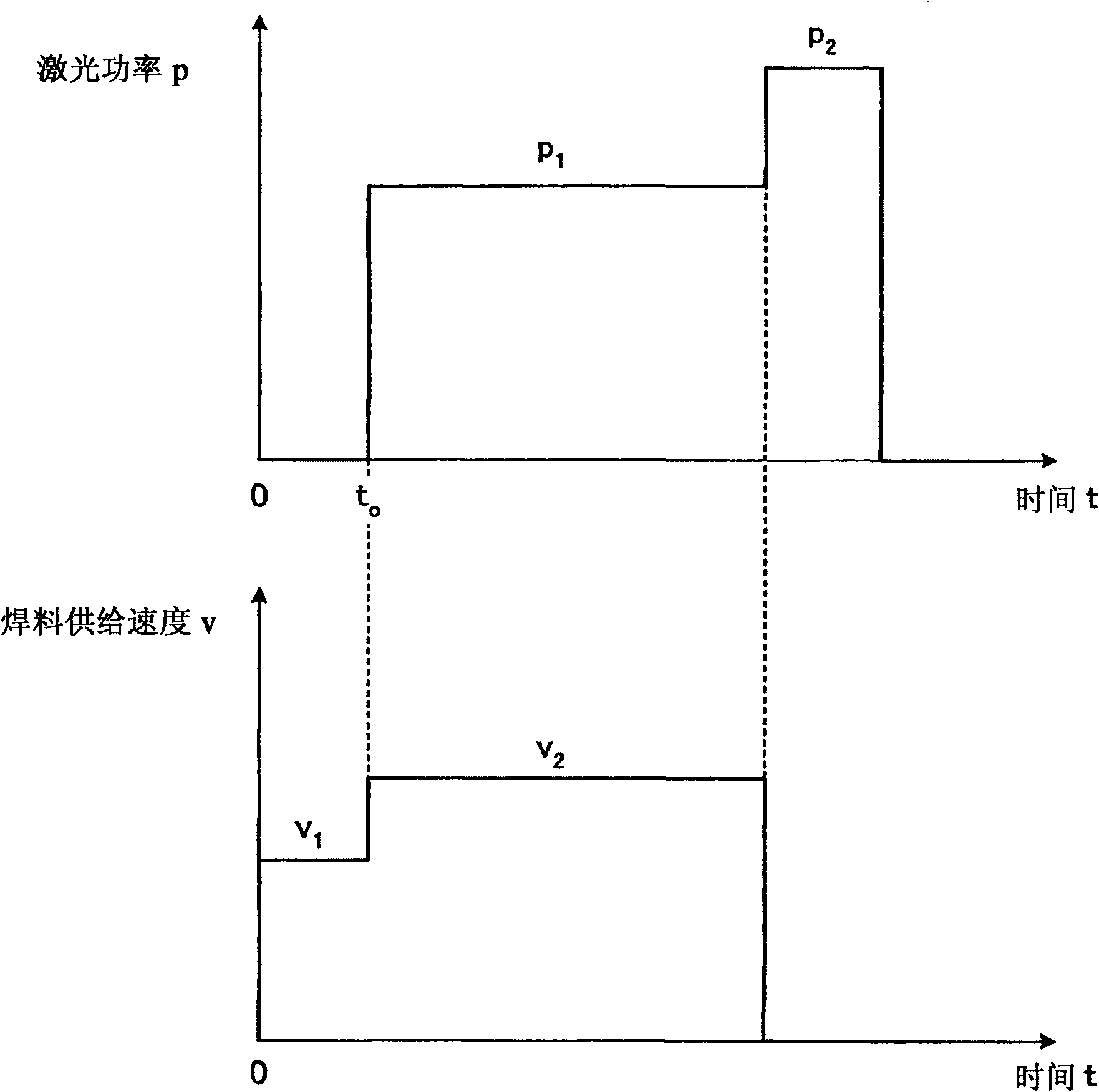

[0031] figure 2 It is a figure which shows an example of the joining condition curve of wire supply speed v and laser power p. The bonding conditions are based on the heat capacity of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com