Solvent recycling and separating device

A separation device and solvent technology, applied in the field of solvent recovery and separation devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

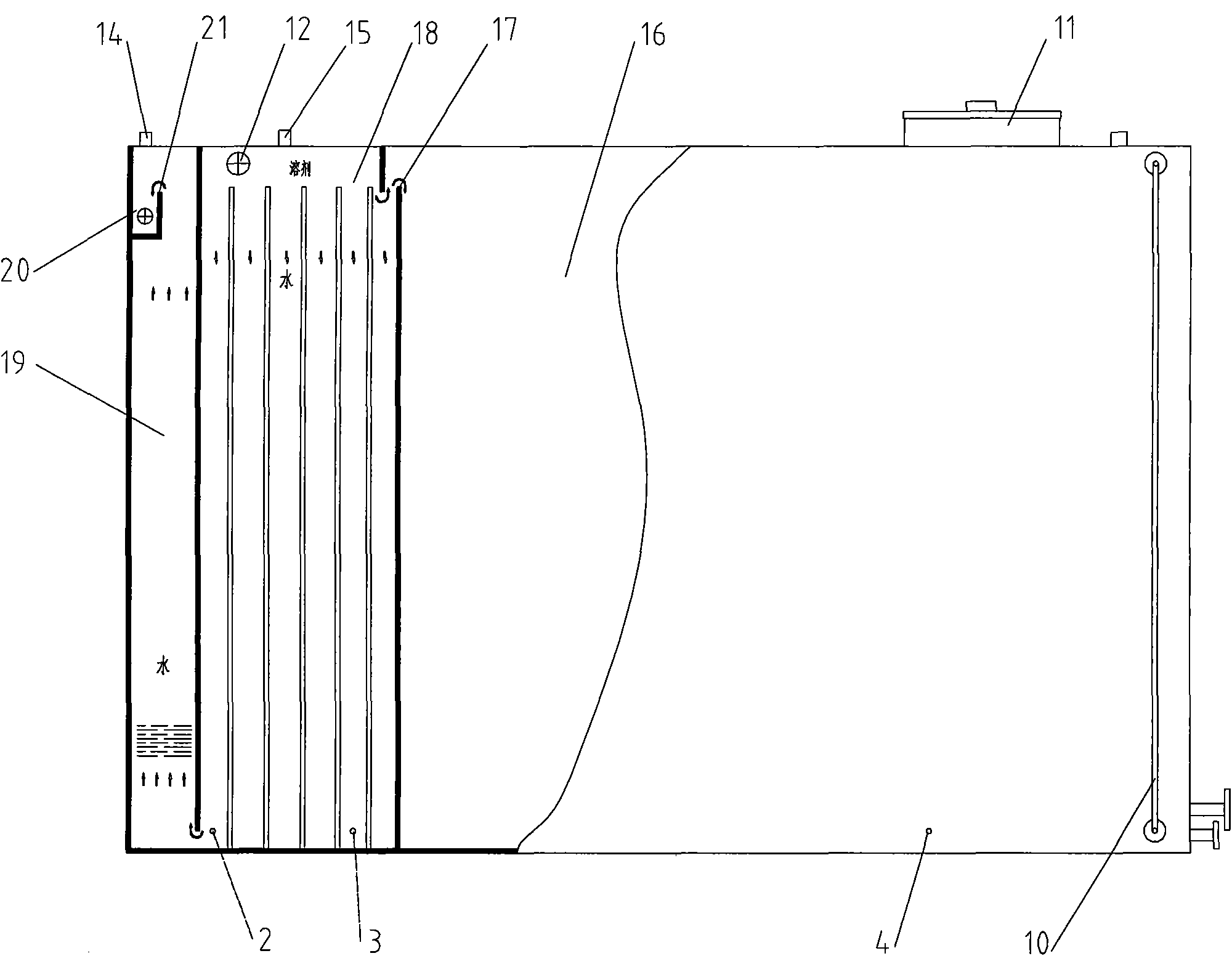

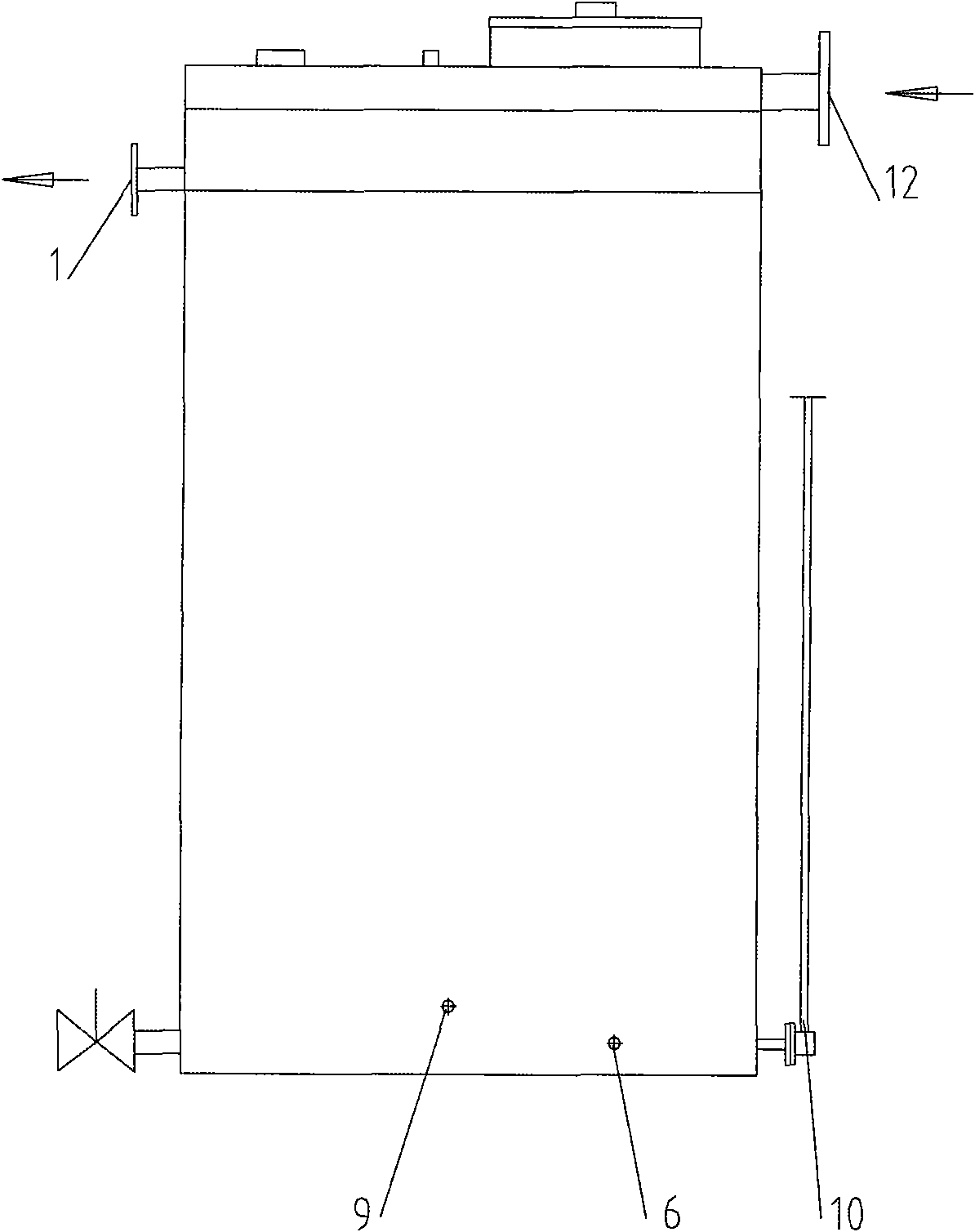

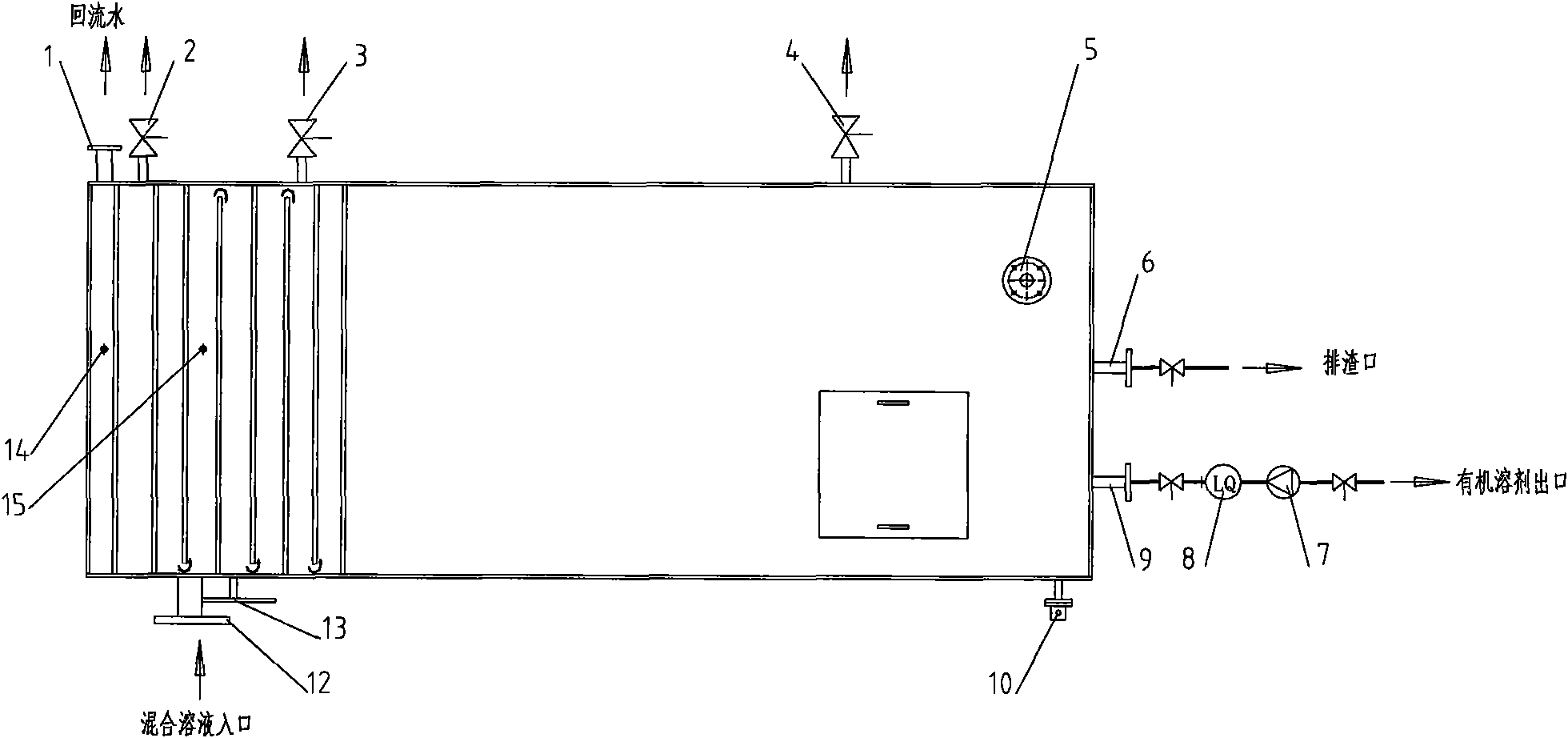

[0011] Such as Figure 1~3 As shown, the embodiment of the present invention is provided with a sealed container welded by stainless steel plates, and the interior of the container is divided into 4 solution chambers 16, 18, 19, and 20.

[0012] The interior of the container is divided into four solution chambers: oil storage chamber 16, buffer chamber 18, water storage chamber 19 and water outlet chamber 20. The buffer chamber 18 is provided with a mixed solution inlet 12, and the oil storage chamber 16 is provided with an organic solvent outlet 9 and a slag discharge port. 6. The slag discharge port 6 is used to discharge the cleaning liquid when cleaning the container regularly. The oil storage chamber 16 and the buffer chamber 18 are respectively provided with a drain port 4 and a drain port 3 . The water outlets 4 and 3 respectively provided on the oil storage chamber 16 and the buffer chamber 18 are used to get rid of the sediment mixed in the organic solvent. The wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com