Composite roller

A composite rolling and rolling technology, which is applied in the direction of rolling, metal rolling, metal rolling, etc., can solve the problems of damage to the hardened layer, low service life, and difficulty in implementation, so as to facilitate precise processing and precise installation, and improve resistance Torque performance, ease of processing and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

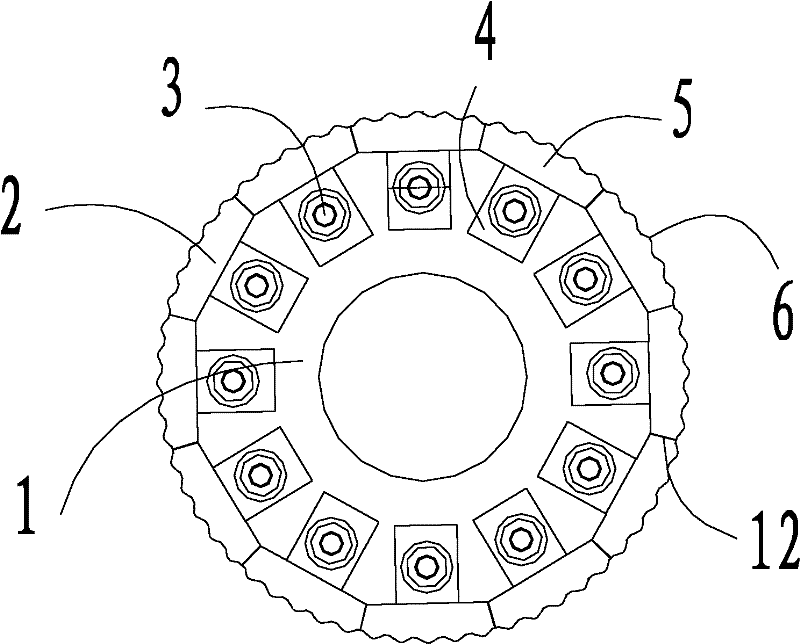

[0066] Such as Figure 1 to Figure 6 As shown, the composite rolling roll includes a roll ring 2 and a core roll 1, the cross section of the core roll 1 is a regular 12-sided shape, and the outer surface of the core roll 1 forms 12 mounting surfaces 7, and the roll ring 2 is composed of Composed of 12 slugs 5, the 12 slugs 5 correspond to the 12 installation surfaces 7 one by one, the bottom surface 10 of each slug 5 fits and contacts with the corresponding installation surface 7 respectively, the bottom surface of each slug 5 There are 3 column pins on the top, and 3 pin holes are provided on the corresponding mounting surface 7, and the above column pins are embedded in the pin holes one by one, and the two ends of each insert 5 are respectively provided with insert legs 4, which correspond to the The two ends of the mounting surface 7 corresponding to the insert block 5 are respectively provided with insert grooves 8 adapted to the above-mentioned insert legs 4, and the abo...

Embodiment 2

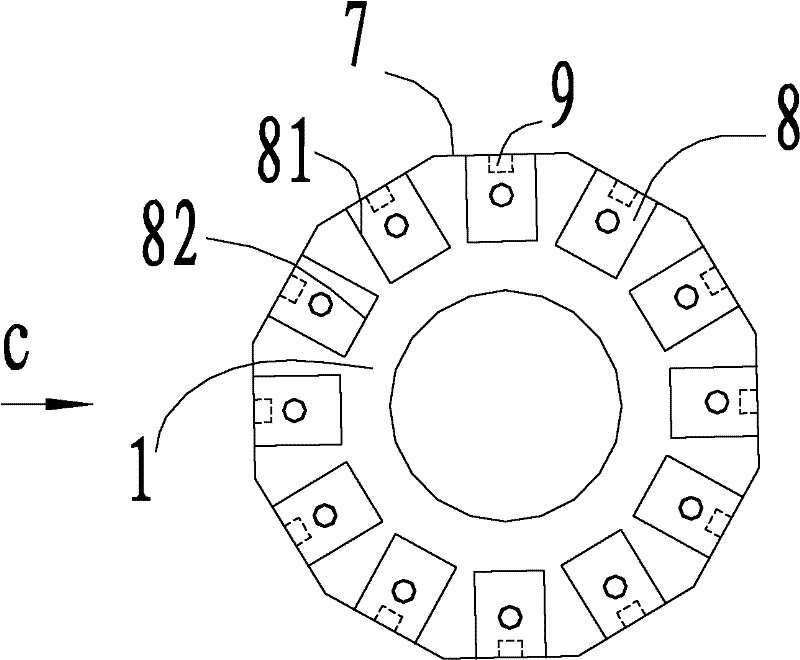

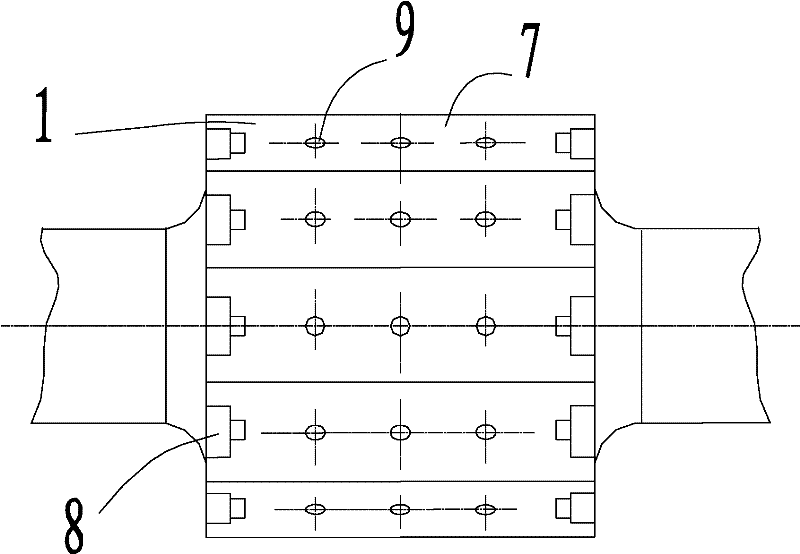

[0068] Such as figure 1 as well as Figure 7 to Figure 12 As shown, the composite rolling roll includes a roll ring 2 and a core roll 1, the cross section of the core roll 1 is a regular 12-sided shape, and the outer surface of the core roll 1 forms 12 mounting surfaces 7, and the roll ring 2 is composed of 12 slugs 5, the 12 slugs 5 correspond to the 12 installation surfaces 7 one by one, the bottom surface 10 of each slug 5 fits and contacts with the corresponding installation surface 7 respectively, and the two slugs of each slug 5 Inlay legs 4 are respectively provided at the ends, and the two ends of the mounting surface 7 corresponding to the inlay block 5 are respectively provided with inlay grooves 8 adapted to the above-mentioned inlay legs 4, and a convex key is arranged on the bottom surface of each inlay block 5, so that The convex key extends from one end of the bottom surface 10 of the inlay block 5 to the other end, and the two ends of the convex key are respec...

Embodiment 3

[0070] The manufacturing method of the slug of compound roll, comprises the following steps:

[0071] A, through the electroslag furnace and the crystallizer one-time forming, form the fusion casting of one-piece structure, wherein, the fusion casting comprises the described inlay block, inlay leg and convex key, and the material composition of the fusion casting comprises by weight percentage:

[0072] C: 0.30-4.00%, Cr: 3.0-7.0%, Ni: 0.5-3.0%, Mo: 0.30-1.0%, W: 0.5-2.0%, V: 0.20-0.80%,

[0073] Ti: 0.10-0.50%, B: 0.001-0.05%, Nb: 0.05-1.50%, N: 0.50-1.50%, and the rest is Fe;

[0074] B. Anneal the molten casting, wherein the annealing process is: put into the furnace at normal temperature, heat up to 650°C with the furnace and keep it for 2.5 to 3 hours, continue to heat up to 920°C and keep it for 4 to 4.5 hours, and slowly cool with the furnace to 600°C The following, out of the oven and air-cooled;

[0075] C, carry out rough machining to the melting and casting that st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com