Granular activated carbon prepared from xanthoceras sorbifolia bunge aril and process thereof

A technology of granular activated carbon and process method, which is applied in chemical instruments and methods, other chemical processes, etc., can solve the problems that have not yet been developed and utilized, and achieve the effects of reduced production cost, simple preparation process and good adsorption performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

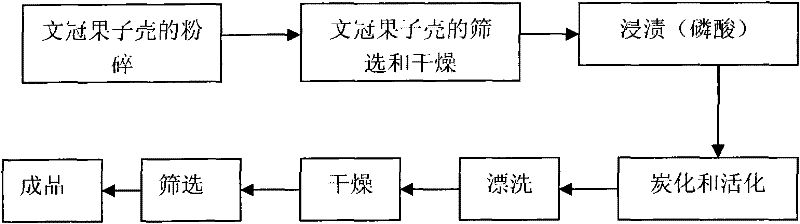

[0020] Embodiment 1: as figure 1 Shown, a kind of processing method that prepares granular activated carbon with Xantho sorbifolia husk is made up of following steps: (1) pulverizes Xantho sorbifolia seed husk, dries after the pretreatment of sieving, pulverizes and sieves again, selects 20 order granules , The pulverized material of Demania crocus seed shell is dried in a constant temperature electric drying oven, and the drying in the drying oven requires a constant temperature, and the temperature is 90°C. Reduce the moisture content of the crushed sorbifolia seed shells to below 10%; put the pretreated radix sorbifolia granules into a pulverizer for further crushing, crush the radix sorbifolia shells and sieve them, and select 60-mesh radix sorbifolia fruits shell particles;

[0021] (2) acid leaching: get the phosphoric acid solution that the mass percentage concentration is 60%, the sorbetia sorbifolium seed shell pulverization thing in the step (1) and the phosphoric a...

Embodiment 2

[0024] Embodiment 2: as figure 1 Shown, a kind of processing method of preparing granular activated carbon with Xantho sorbifolia husk is made up of following steps: (1) pulverizes radix sorbifolia seed husk, dries after the pretreatment of sieving, pulverizes and sieves again, selects 60 mesh particles , The pulverized product of Dementia crocus seed shells was dried in a constant temperature electric drying oven, and the drying in the drying oven required a constant temperature, and the temperature was 110°C. Reduce the moisture content of the crushed sorbifolia seed shells to less than 10%; put the pretreated radix sorbifolia granules into a pulverizer for further crushing, crush the radix sorbifolia shells and sieve them, and select 120-mesh radix sorbifolia fruits shell particles;

[0025] (2) acid leaching: get the phosphoric acid solution that the mass percentage concentration is 90%, the sorbetia sorbifolium seed shell pulverization thing in the step (1) and the phosp...

Embodiment 3

[0028] Embodiment 3: as figure 1 Shown, a kind of processing method that prepares granular activated carbon with Xantho sorbifolia husk is made up of following steps: (1) pulverizes Xantho sorbifolia seed husk, dries after the pretreatment of sieving, pulverizes and sieves again, selects 40 order granules , The pulverized material of Demania crocus seed shell is dried in a constant temperature electric drying oven, and the drying in the drying oven requires a constant temperature, and the temperature is 100°C. Reduce the moisture content of the crushed sorbifolia seed shells to below 10%; put the pretreated radix sorbifolia granules into a pulverizer for further crushing, crush the radix sorbifolia shells and sieve them, and select 90-mesh radix sorbifolia fruits shell particles;

[0029] (2) acid leaching: get the phosphoric acid solution that the mass percentage concentration is 75%, with the mass percentage concentration of preparation in step (1), the sorbium sorbifolium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com