Double-layer high-efficiency superfine-micropore aeration header

An aeration head and ultra-fine technology, applied in water aeration, sustainable biological treatment, water/sludge/sewage treatment, etc., can solve the problems of low efficiency and high energy consumption, and achieve high strength, good air permeability, The effect of reducing drag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

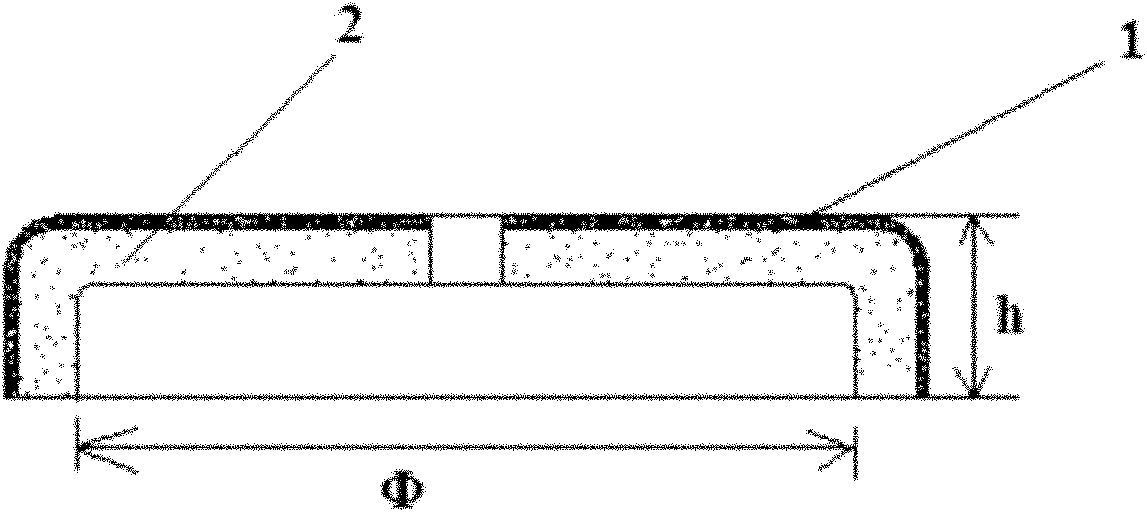

[0039] Such as figure 1 As shown, a double-layer high-efficiency ultra-fine microporous aerator head, the inner layer is a conventional brown corundum aerator head 1, and the outer surface of the brown corundum aerator head is coated with a layer of superfine corundum with a thickness of 0.5 mm and a pore diameter of 65 μm. Microporous layer 2. The wall thickness of the conventional brown corundum aeration head 1 in the inner layer is 13 mm, the aperture is 180 μm, the shape is bell-shaped, the diameter is 200 mm, and the height is 38 mm.

[0040] The double-layer high-efficiency ultra-fine microporous aeration head can be prepared by the following method:

[0041] (1) Use brown corundum sand with a particle size of 50 meshes, add wood chips equivalent to 6% of the weight of brown corundum sand and yellow dextrin materials equivalent to 3% of the weight of brown corundum sand, and mix them mechanically to make an exposed corundum with a wall thickness of 13mm. The air head i...

Embodiment 2

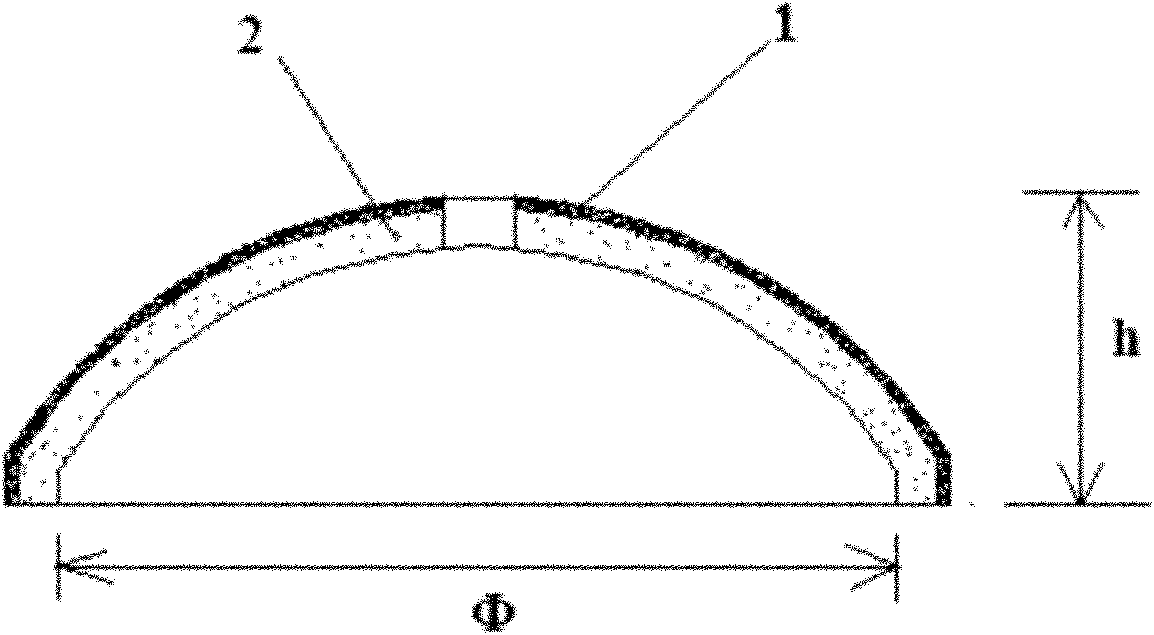

[0044] Such as figure 2 As shown, a double-layer high-efficiency ultra-fine microporous aerator head, the inner layer is a conventional brown corundum aerator head 1, and the outer surface of the brown corundum aerator head is coated with a layer of brown corundum precision with a thickness of 0.3 mm and a pore diameter of 56 μm. Microporous layer 2. The wall thickness of the conventional brown corundum aeration head 1 in the inner layer is 12 mm, the aperture is 150 μm, the shape is a circular arch, the diameter is 300 mm, and the radius of the circular arch is 100 mm.

[0045] The double-layer high-efficiency ultra-fine microporous aeration head can be prepared by the following method:

[0046] (1) Use brown corundum sand with a particle size of 45 meshes, add wood chips equivalent to 3% of the weight of brown corundum sand and yellow dextrin materials equivalent to 1% of the weight of brown corundum sand, and mix them mechanically to make an exposed corundum with a wall t...

Embodiment 3

[0049] Such as figure 1 As shown, a double-layer high-efficiency ultra-fine microporous aerator head, the inner layer is a conventional brown corundum aerator head 1, and the outer surface of the brown corundum aerator head is coated with a layer of white corundum with a thickness of 0.7mm and a pore diameter of 80μm. Microporous layer 2. The wall thickness of the conventional brown corundum aeration head 1 in the inner layer is 14 mm, the aperture is 250 μm, the shape is bell-shaped, the diameter is 200 mm, and the thickness is 40.

[0050] The double-layer high-efficiency ultra-fine microporous aeration head can be prepared by the following method:

[0051] (1) Use brown corundum sand with a particle size of 65 meshes, add wood chips equivalent to 5% of the weight of brown corundum sand and yellow dextrin materials equivalent to 2% of the weight of brown corundum sand, and mix them mechanically to make an exposed corundum with a wall thickness of 14mm. The air head is drie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com