High pressure common rail device with variable high pressure volume for high pressure common rail fuel system

A high-pressure common rail and fuel system technology, applied in fuel injection devices, charging systems, engine components, etc. Affect the fuel injection accuracy of the injector and other problems, achieve the effect of quick start, maintain pressure stability, and eliminate pressure fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

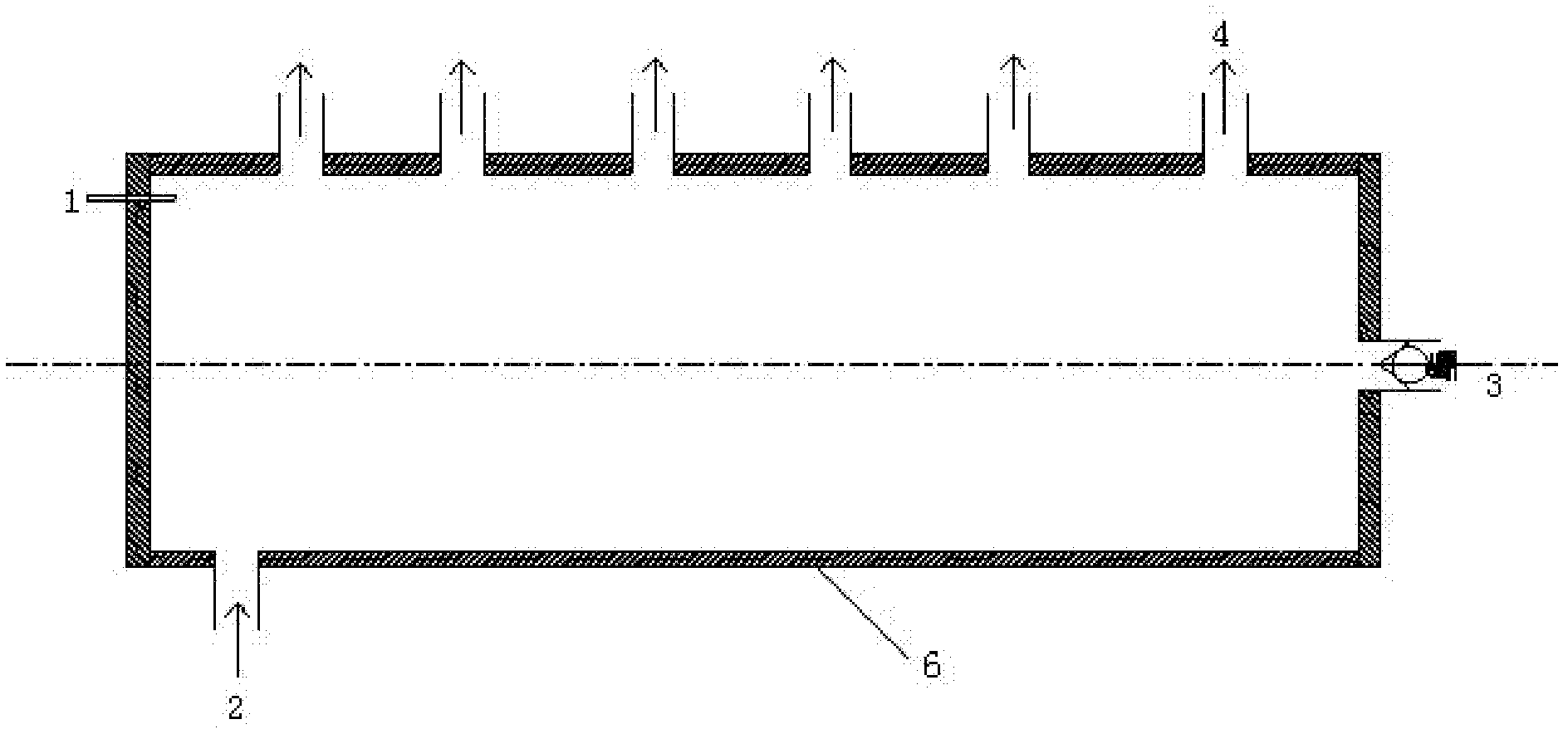

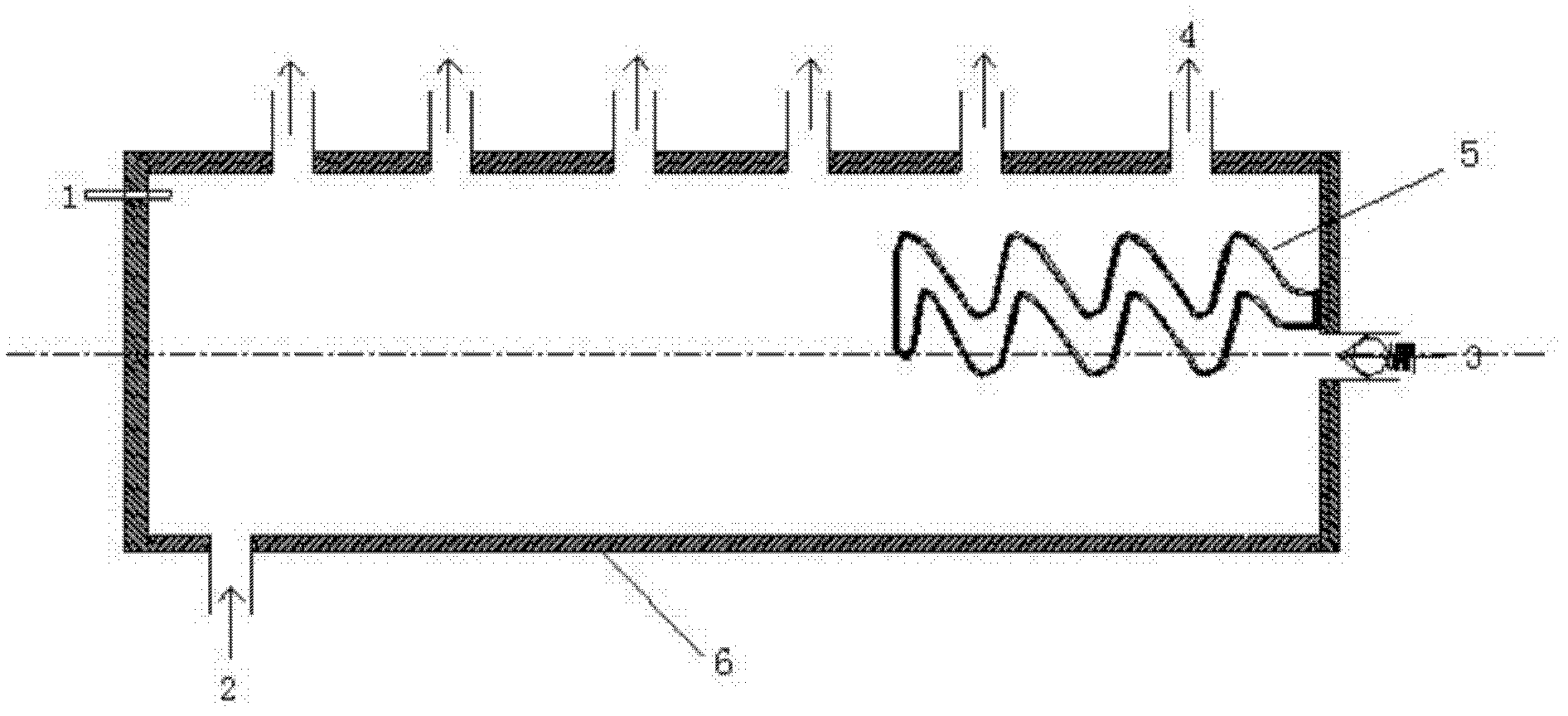

[0015] The specific technical solution of the present invention is that on the basis of the original high-pressure oil rail device of the present invention, an elastic sealing cavity is added in the high-pressure oil rail, and the two are connected by welding. A rail pressure sensor, oil inlet, pressure limiting valve and 6 oil outlets are installed on the high-pressure fuel rail. Fuel flows into the high-pressure fuel rail through the fuel inlet. The electronic control system measures the pressure in the high-pressure fuel rail through the rail pressure sensor. For safety, when the fuel pressure exceeds the limit value, the pressure limiting valve will open, and the fuel will flow out of the high-pressure fuel rail. Fuel can flow out of the fuel injectors injected into each cylinder through the fuel outlet. The structural diagram of the original high-pressure oil rail device is attached figure 1 shown.

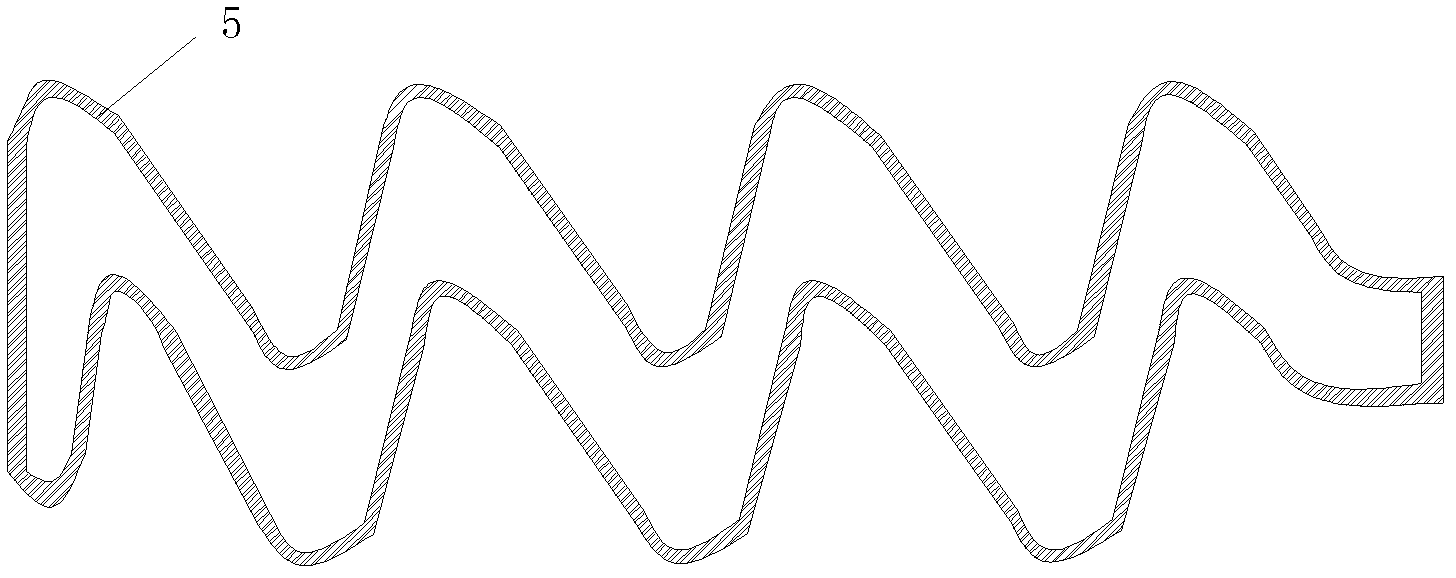

[0016] The elastic sealing chamber is made of metal material with a bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com