Dewaxing device and process

A dewaxing and equipment technology, which is applied in casting molding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of high boiler investment and maintenance costs, high energy consumption, long heating time, etc., and achieve full use of energy and fast heating , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

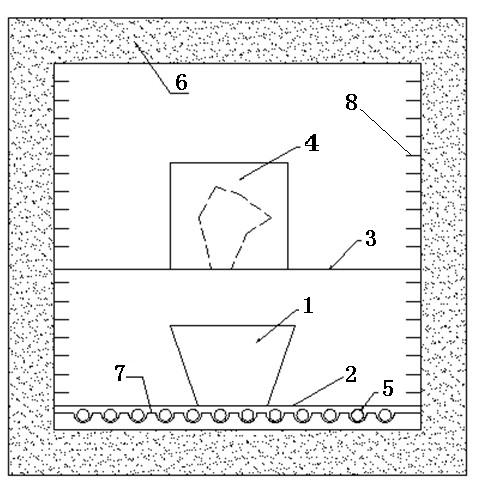

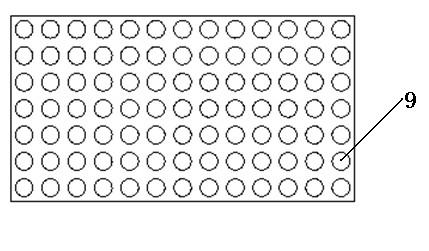

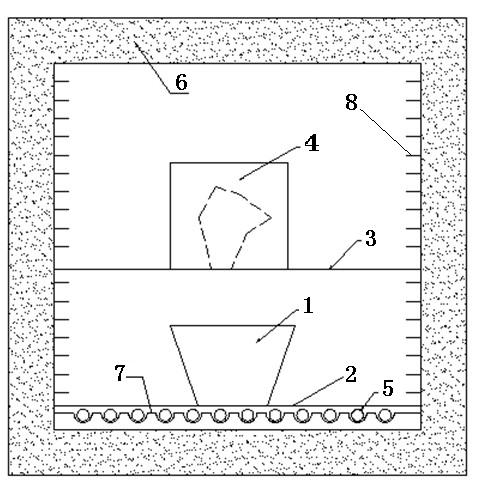

[0019] Such as figure 1 , 2 Described: a dewaxing equipment, comprising a dewaxing box 6, characterized in that: a refractory material 7 is laid on the inner bottom surface of the dewaxing box 6, and a resistance wire 5 connected to a power supply is arranged on the refractory material 7, The dewaxing box 6 above the resistance wire 5 is provided with a container support plate 2 and a wax mold support plate 3 sequentially from bottom to top. Small holes 8 are all provided. The small holes provided on the container support plate 2 are for the heat conduction container 1 to be evenly heated when the resistance wire is heated, and the small holes provided on the wax mold support plate 3 are used to make the melted wax liquid flow into the heat conduction container 1, Moreover, the speed of heating up and melting of the wax pattern 4 is also improved, and the efficiency is improved. The inner walls of both sides of the dewaxing box 6 are equidistantly provided with support plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com