Continuous casting method of high chrome steel

A high-chromium steel and continuous casting technology, applied in the field of iron and steel metallurgy, can solve problems such as shrinkage cavities, slag pits on the surface of slabs, slag inclusions, and segregation of slabs, and achieve low production costs, stable quality, and low defective rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1 uses the continuous casting method of the present invention to cast L80-3Cr high chromium steel

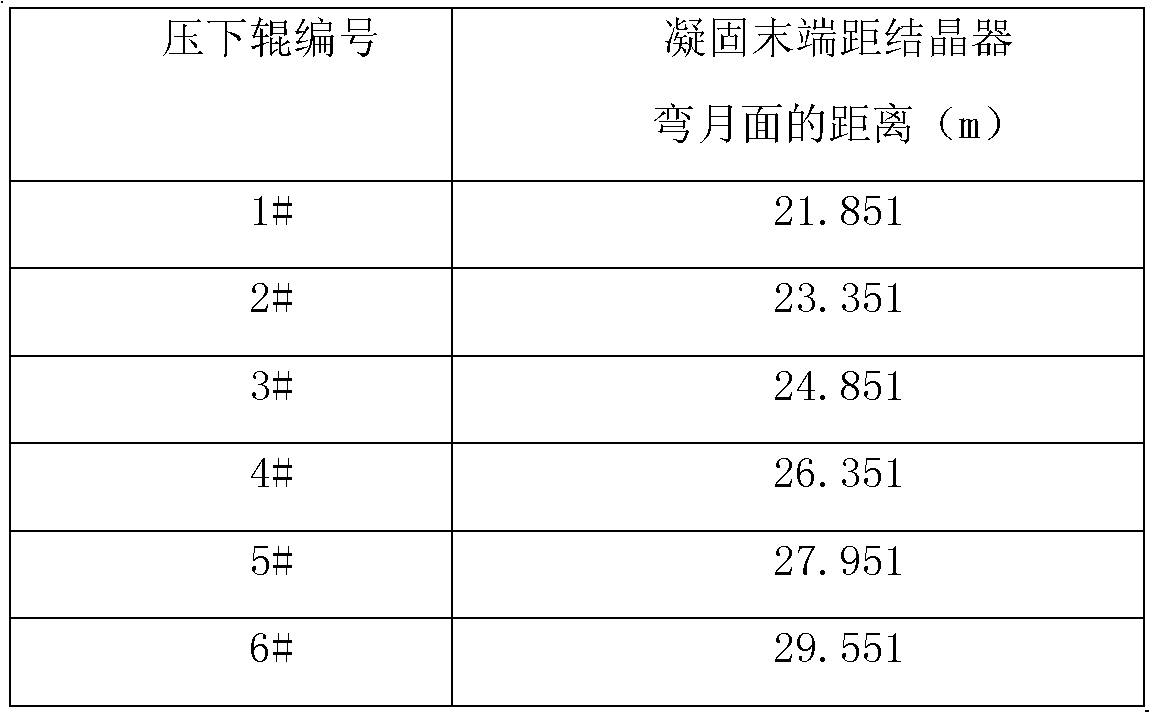

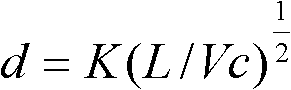

[0030] What this embodiment adopts is a 360mm×450mm four-machine four-strand bloom continuous casting machine, which is manufactured by CCID Company of China Metallurgical Corporation. First put the mold flux into the mold of the continuous casting machine. The composition of the mold flux is calculated by weight percentage: SiO 2 : 35%, CaO: 22%, Al 2 O 3 : 4%, MgO: 4%, Na 2 O: 11%, F - : 3%, C: 12%, Fe 2 O 3 : 1.5%, the rest are impurities. AlkalinityCaO / SiO 2 : 0.63, hemispherical point melting temperature: 1082°C, viscosity at 1300°C: 0.32Pa·s. The amount of mold slag used is 0.45kg / ton of steel. The molten steel with a superheat of 16°C after refining is injected into the crystallizer through the submerged nozzle. At this time, the temperature of the molten steel is 1526°C. 0.011%, sulfur 0.007%, chromium 2.92%, molybdenum 0.42%, all aluminum 0.0...

Embodiment 2

[0041] Embodiment 2 uses the continuous casting method of the present invention to cast L80-3Cr high chromium steel

[0042] What this embodiment adopts is 360mm * 450mm four-machine four-strand bloom continuous casting machine. First put the mold flux into the mold of the continuous casting machine. The composition of the mold flux is calculated by weight percentage: SiO 2 : 37%, CaO: 25%, Al 2 O 3 : 4.2%, MgO: 4.1%, Na 2 O: 10.5%, F - : 3.2%, C: 11.8%, Fe 2 O 3 : 1.6%, the rest are impurities. AlkalinityCaO / SiO 2 : 0.67, hemispherical point melting temperature: 1089°C, viscosity at 1300°C: 0.35Pa·s. The amount of mold slag used is 0.40kg / ton of steel. The molten steel with a superheated degree of 22°C after refining is injected into the crystallizer through the submerged nozzle. At this time, the temperature of the molten steel is 1532°C. 0.012%, sulfur 0.007%, chromium 2.98%, molybdenum 0.47%, all aluminum 0.03%, and the balance is iron and impurities. The molten...

Embodiment 3

[0046] Embodiment 3 uses the continuous casting method of the present invention to cast L80-3Cr high chromium steel

[0047] What this embodiment adopts is 360mm * 450mm four-machine four-strand bloom continuous casting machine. First put the mold flux into the mold of the continuous casting machine. The composition of the mold flux is calculated by weight percentage: SiO 2 : 36%, CaO: 25%, Al 2 O 3 : 4.8%, MgO: 3.7%, Na 2 O: 11.2%, F - : 3.4%, C: 13%, Fe 2 O 3 : 1.2%, the rest are impurities. AlkalinityCaO / SiO 2: 0.69, hemispherical point melting temperature: 1115°C, viscosity at 1300°C: 0.39Pa·s. The amount of mold slag used is 0.35kg / ton of steel. The molten steel with a superheat of 30°C after refining is injected into the crystallizer through the submerged nozzle. At this time, the temperature of the molten steel is 1540°C. 0.010%, sulfur 0.006%, chromium 3.15%, molybdenum 0.42%, all aluminum 0.02%, and the balance is iron and impurities. The molten steel in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com