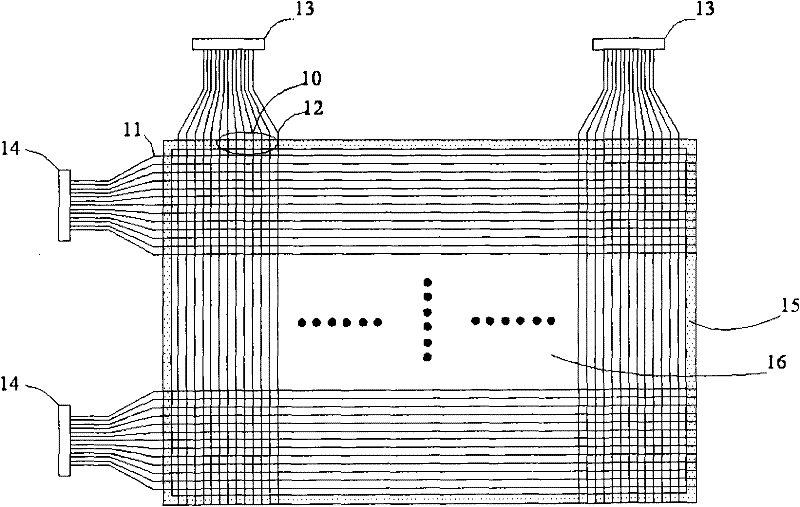

Array substrate and liquid crystal display panel

A technology of array substrate and transparent substrate, applied in the field of liquid crystal display, can solve the problems of slow photocuring of sealant, reduced production efficiency, increased power consumption, etc., and achieves the effects of reducing production cost, improving production efficiency and increasing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

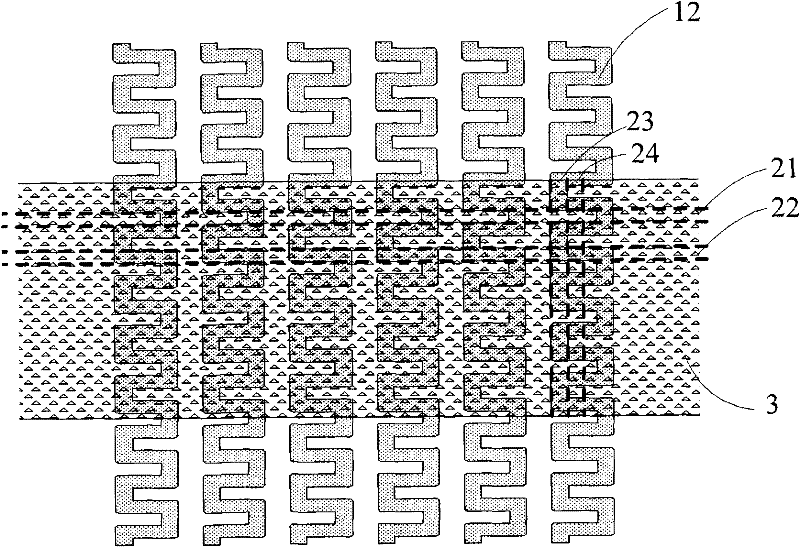

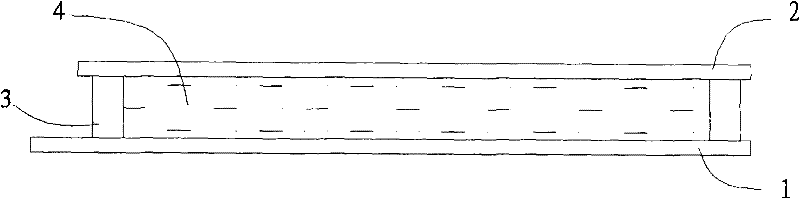

[0023] Figure 4 It is a partially enlarged schematic diagram of the wiring of the thin film transistor array substrate in the liquid crystal display panel according to the first embodiment of the present invention. A plurality of wirings are located under the frame glue 3, and the area covered by the frame glue 3 is the frame glue area. The multiple wirings can be scanning lines or data lines. All the following implementation methods will use the wiring as the data line 12 as an example. For detailed description, of course, the present invention is also applicable to the case where a plurality of wirings are scanning lines. Such as Figure 4 As shown, the plurality of wirings are data lines 12 . In the sealant area, any data line 12 among the multiple data lines 12 has a periodic wave bending pattern, the period of the wave bending pattern is T1, and the wave bending pattern is square in each period T1. Wavy zigzag pattern. The square-wave bending pattern of any data line...

no. 2 approach

[0027] The similarities between the second embodiment and the first embodiment will not be repeated. Figure 5 It is a partially enlarged schematic diagram of the wiring of the thin film transistor array substrate in the liquid crystal display panel according to the second embodiment of the present invention. Compared with the first embodiment, the second embodiment is different in that, in the second embodiment, the square-wave bending patterns between adjacent data lines 12 are arranged with a 3 / 4 cycle offset from each other, Figure 5 The arrangement of the even-numbered data lines 12 can be regarded as the result of the downward translation of the odd-numbered data lines 12 by 3 / 4 of the period of the square-wave bending pattern. Figure 5 Take the horizontal narrow and long regions 51 and 52 respectively, the width of which is 1 / 4 of the bending period of the square wave of the data line 12, and the length is the total length a of the frame glue in the transverse directi...

no. 3 approach

[0031] The difference between the third embodiment of the present invention and the above-mentioned first and second embodiments is that the first and second embodiments only consider making the light-receiving area of the sealant uniform in the transversely long and narrow region perpendicular to the longitudinal extension direction of the data lines, The third embodiment comprehensively considers the longitudinally long and narrow areas along the longitudinal extension of the data lines and the transversely long and narrow areas perpendicular to the longitudinal extension of the data lines, so that the light-receiving area of the frame glue is as uniform as possible.

[0032] The similarities between the third embodiment and the first and second embodiment will not be repeated. Figure 6 It is a partially enlarged schematic diagram of the wiring of the thin film transistor array substrate in the liquid crystal display panel according to the third embodiment of the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com