Light emitting diode and manufacturing method thereof

A technology of light-emitting diodes and manufacturing methods, which is applied in the direction of electrical components, electrical solid devices, circuits, etc., and can solve the problems of unsatisfactory light emitting angle, height and optical density of a single LED, high processing cost of a single SMD, and poor consistency of phosphor distribution And other problems, to achieve the effect of good macroscopic visual effect, good batch operation consistency, and good anti-UV performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

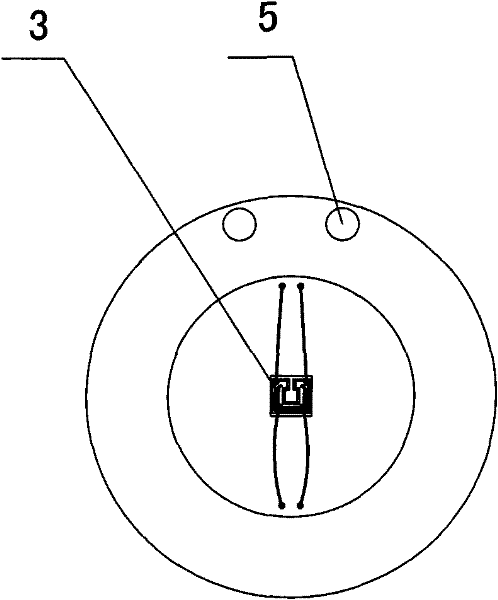

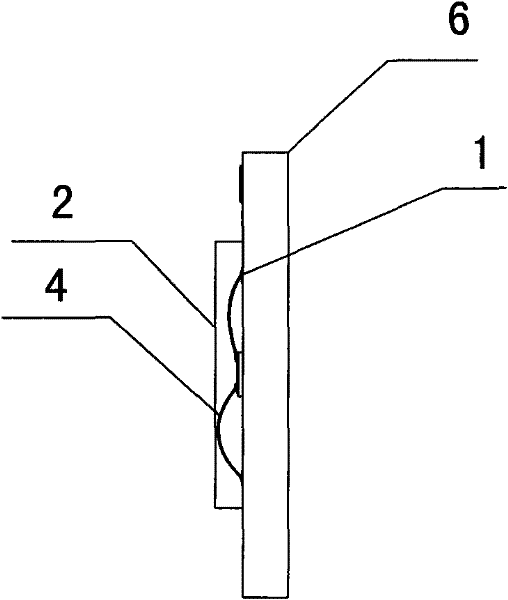

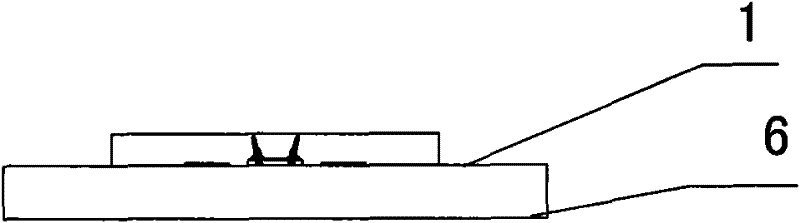

[0059] The invention discloses a light emitting diode, such as figure 1 , 2 , 3, including: an electrode set 1, a chip 3 installed on the front of the electrode set 1, a connection 4 and an electrode 5, wherein the light-emitting diode adopts a two-layer structure, and the electrode set 1 forms the light-emitting diode The first layer; the light-emitting diode also includes a rubber cake 2, the rubber cake 2 covers the front of the electrode set 1, and the chip 3, the wiring 4, and the electrode 5 are covered on the rubber cake 2 and the electrode set 1; the rubber cake 2 forms the second layer of the light emitting diode.

[0060] The COB series adopts a thermoelectric separation structure. The electrode set 1 is the frame of the LED light source device. The rubber cake 2, the chip 3, the connection line 4, the electrode 5, and the heat sink 6 are all fixed and installed through the electrode set 1.

[0061] The electrode assembly 1 includes a substrate, the front of the su...

Embodiment 2

[0080] Such as Figure 5 , in this embodiment, the light-emitting diode includes: an electrode set 1, a chip 3 installed on the front of the electrode set 1, a wire 4, and an electrode 5. The light-emitting diode adopts a two-layer structure, and the electrode set 1 forms the The first layer of the light-emitting diode; the light-emitting diode also includes a rubber cake 2, the rubber cake 2 covers the front of the electrode set 1, and the chip 3, the wiring 4, and the electrode 5 are covered on the rubber cake 2 Between the electrode assembly 1; the rubber cake 2 forms the second layer of the light-emitting diode; wherein, the light-emitting diode also includes a plurality of chips 3, and the plurality of chips 3 are spaced from each other and arranged on the front of the electrode assembly 1; Two or n groups of connecting wires 4 start from the electrodes on the plurality of chips 3 respectively, and respectively connect the chips 3 with the electrodes on the electrode set,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com