Automatic filter-pressing dehydration device and working method thereof

A dehydration equipment, automatic filter press technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of low degree of automation, high maintenance cost, cumbersome maintenance, etc., achieve high degree of automation, convenient and fast maintenance, Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

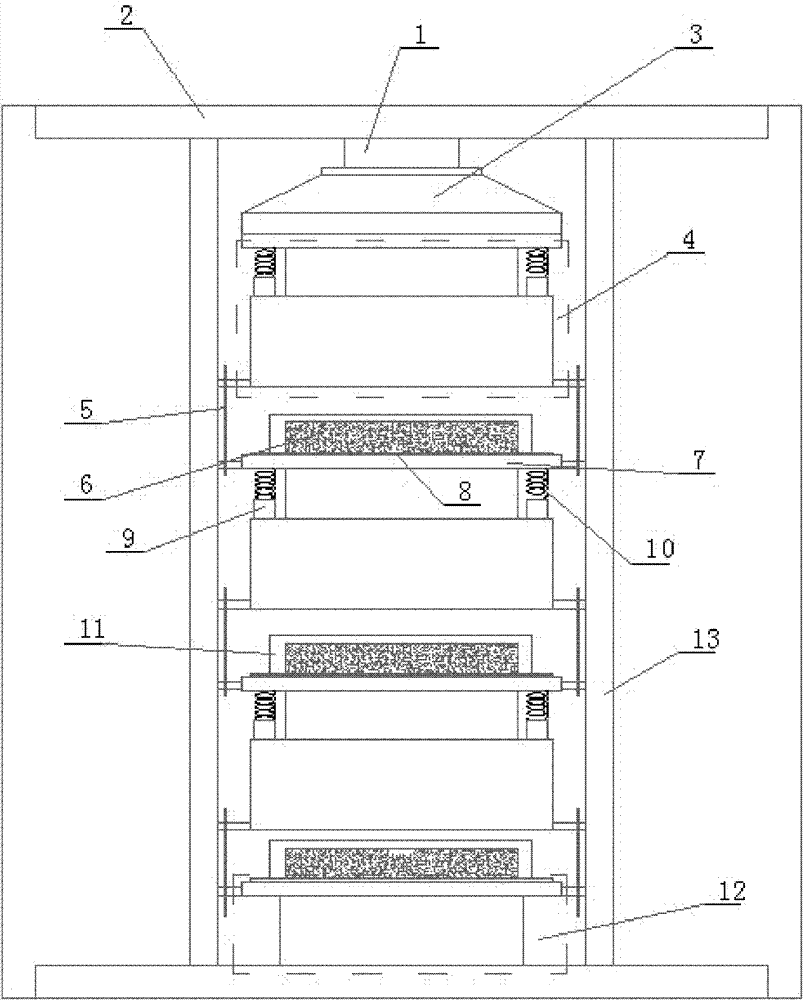

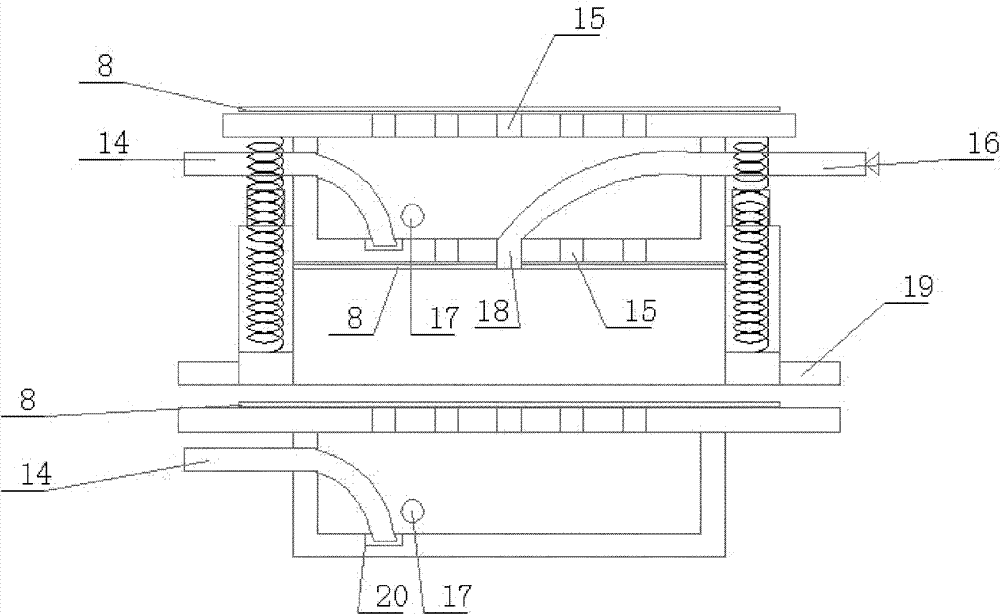

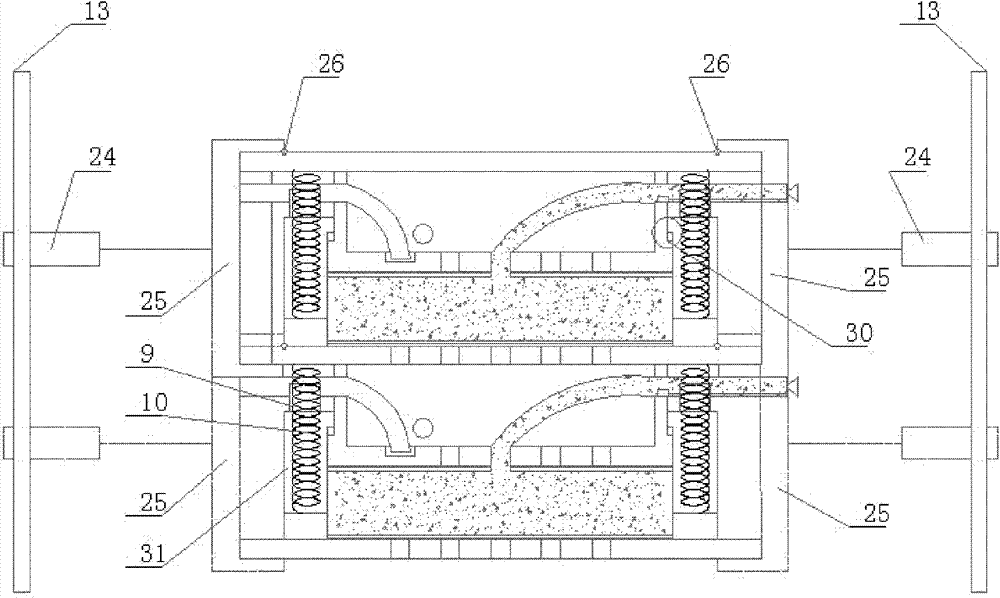

[0049] An automatic filter press dehydration equipment, including a gantry 2, an oil pressure cylinder 1, a pressure plate 3 and a filter plate frame group; the oil pressure cylinder 1 is installed on the top of the gantry 2, and the pressure plate 3 is connected with the oil pressure cylinder 1, The pressure plate 3 is connected with the filter press plate frame group; it is characterized in that, the filter press plate frame set includes a filter press unit 4 and a bottom filter press box 12; the filter press unit 4 is above the bottom filter press box 12, and the filter press Unit 4 comprises filter press plate and filter press frame 22, and described filter press plate comprises top cover, side wall and bottom surface, has high-pressure gas hole 17, feed pipe 16 and liquid outlet pipe 14 on the side wall of press filter plate, in The bottom surface of the filter press plate has a through feed inlet 18, a through hole 15 and a groove 20, and the feed pipe 16 is connected to ...

Embodiment 2

[0055] A kind of working method of automatic press filter dehydration equipment as described in embodiment 1, the steps are as follows:

[0056] 1) Forming the filter chamber: start the equipment, and the computer operating platform controls the hydraulic cylinder 1 to move downward to push the filter unit 4. When the distance between adjacent top covers is smaller than the distance between the two ends of the concave fixture 25, the oil The pressure cylinder 1 remains stationary, and the oil cylinder 24 pushes the concave-shaped fixture 25 to rotate along the pivot; realize the fixing of the size of the pressure filter cavity;

[0057] 2) Filling: The computer operating platform controls the feed pump to start feeding, and at the same time controls the pressure sensor to collect pressure data. The feed pump feeds the filter chamber in the filter press frame 22 through the feed pipe 16. When the filter press chamber When the pressure is 1MPa, the feed pump stops feeding, and t...

Embodiment 3

[0063] Automatic press filter dehydration equipment as described in embodiment 1, its difference is,

[0064] The number of the filter press units 4 is 6, and sealing parts are arranged symmetrically on both sides of the filter press plate frame group. The sealing parts include a bracket 27, an oil cylinder 23 and a sealing block 29. The bracket 27 is fixed on the The lower edge 19 of the frame, the oil cylinder 23 is installed on the bracket 27, the sealing block 29 is slidably installed on the bracket 27, the oil cylinder 23 is connected with the non-working surface of the sealing block 29, when the lower edge of the adjacent filter press frame 22 and the top cover are closed , The oil cylinder 23 pushes the sealing block 29 to clamp the lower edge 19 and the edge of the top cover of the filter press frame.

[0065] The inner surface of the filter press frame has an inclined edge 32, and the included angle between the inclined edge 32 and the horizontal is less than 90 degre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com