Equatorial telescope bracket

An instrument bracket, equatorial technology, applied in the field of equatorial mounts, can solve the problems of inability to realize the automatic star finding function of celestial bodies, time-consuming adjustment process, poor pointing accuracy of the bracket, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and a preferred embodiment.

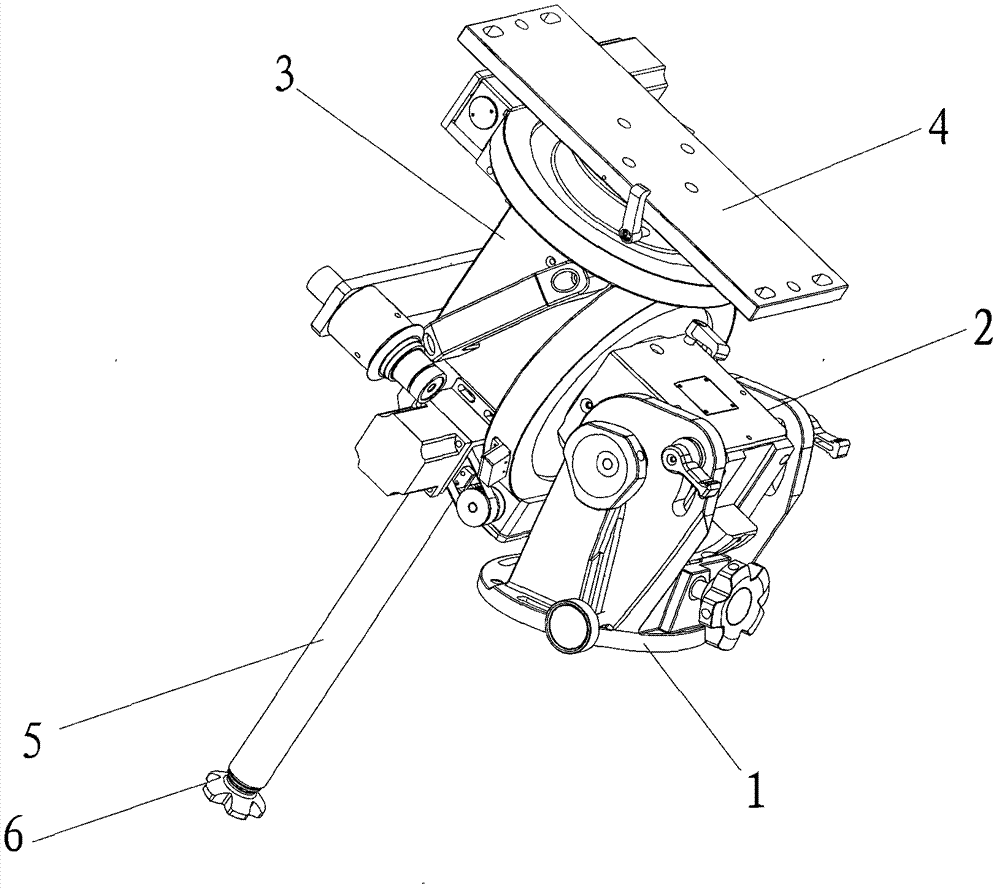

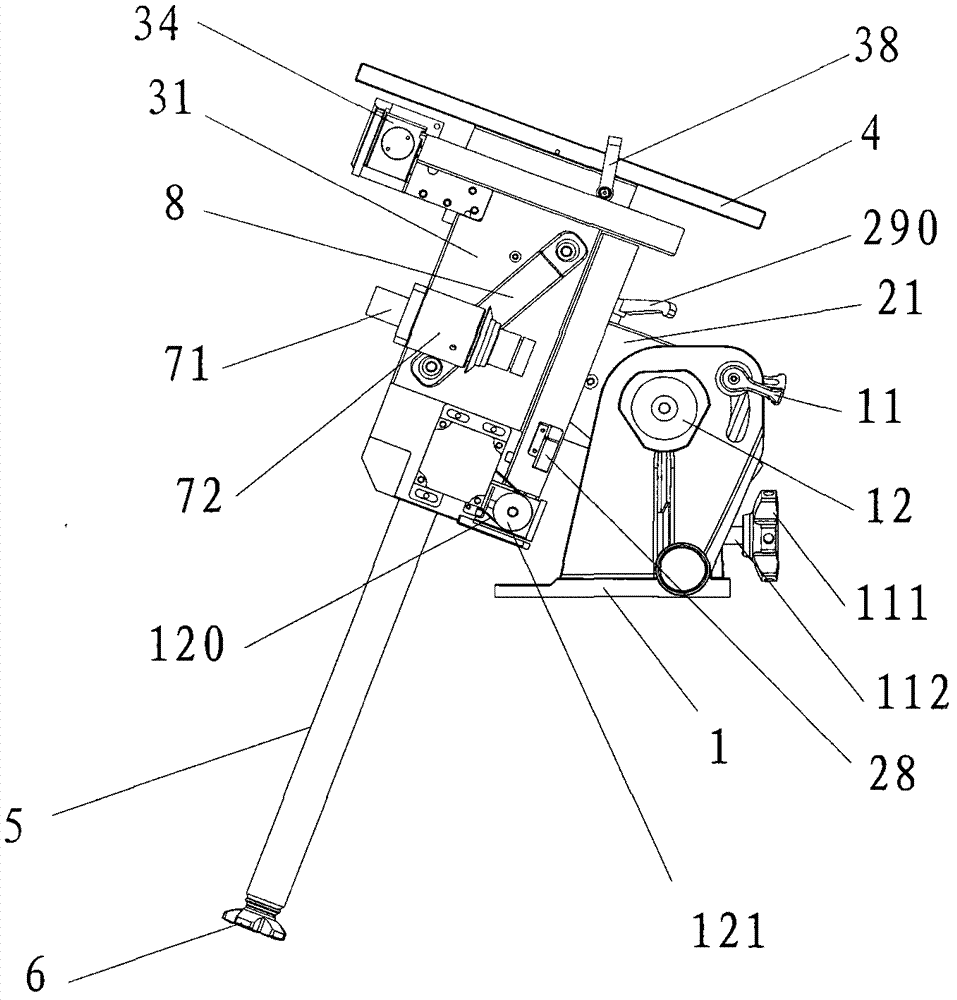

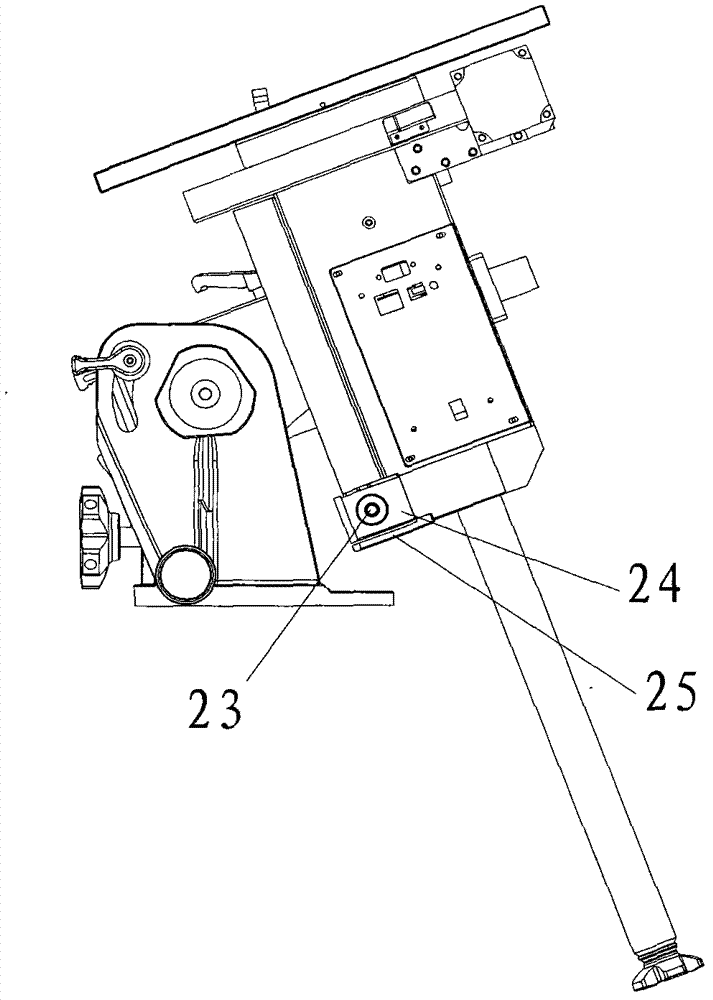

[0034] refer to Figure 1-9 , the equatorial mount bracket includes a base 1, an hour angle mechanism 2 and an angle mechanism 3; the hour angle mechanism 2 is connected to the base 1, and can rotate around a latitude axis driven by a latitude adjustment mechanism; the angle angle Mechanism 3 is connected with hour angle mechanism 2, and can rotate around an hour angle axis under the drive of hour angle drive mechanism; The lens barrel support plate 4 is connected on the described deflection box 3, and the lens barrel support plate can be rotated in the deflection angle drive mechanism Rotate around a deflection axis under driving; Described hour angle driving mechanism comprises hour angle motor 91 and hour angle worm 23, and described hour angle motor and hour angle worm drive connection; Described angle angle driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com