Clamping apparatus for flushing photomask

A card mounting device and photomask technology, which is applied in the photomechanical process of photomechanical processing of originals, optics, and pattern surfaces, etc., can solve the problems of inability to use cleaning technology, large volume, affecting cleaning efficiency, etc. To achieve the effect of reducing installation and debugging time, reasonable and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

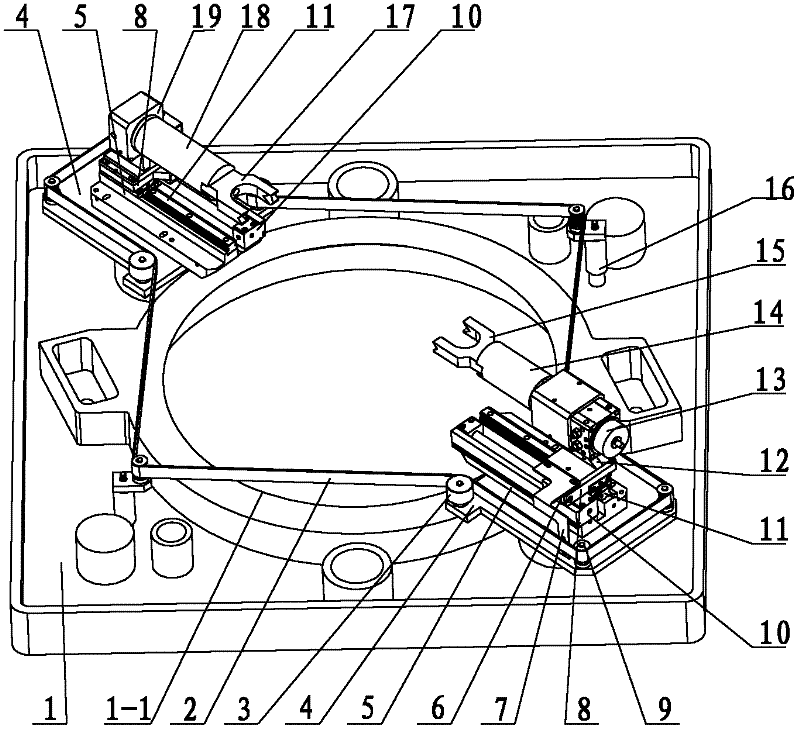

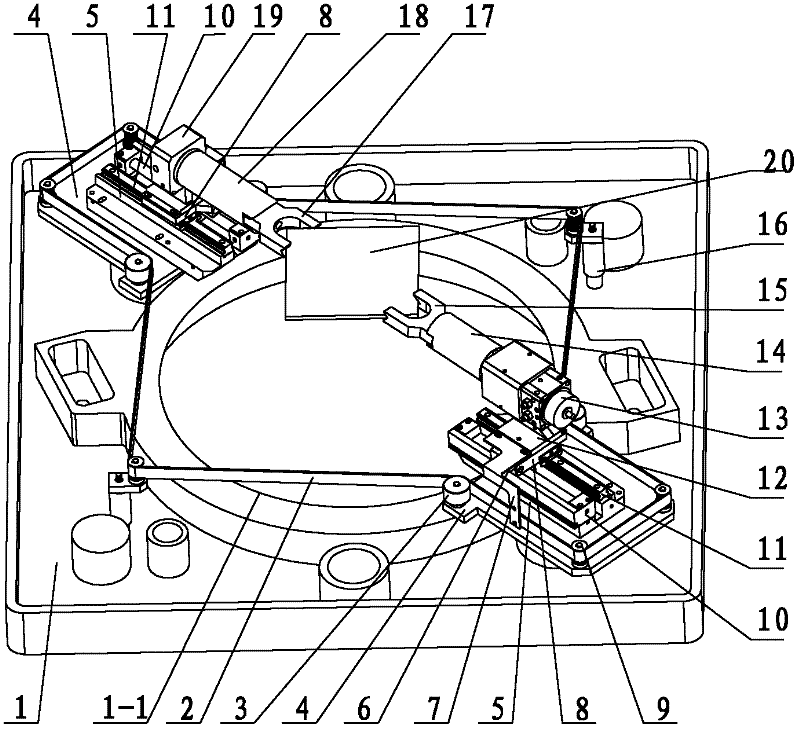

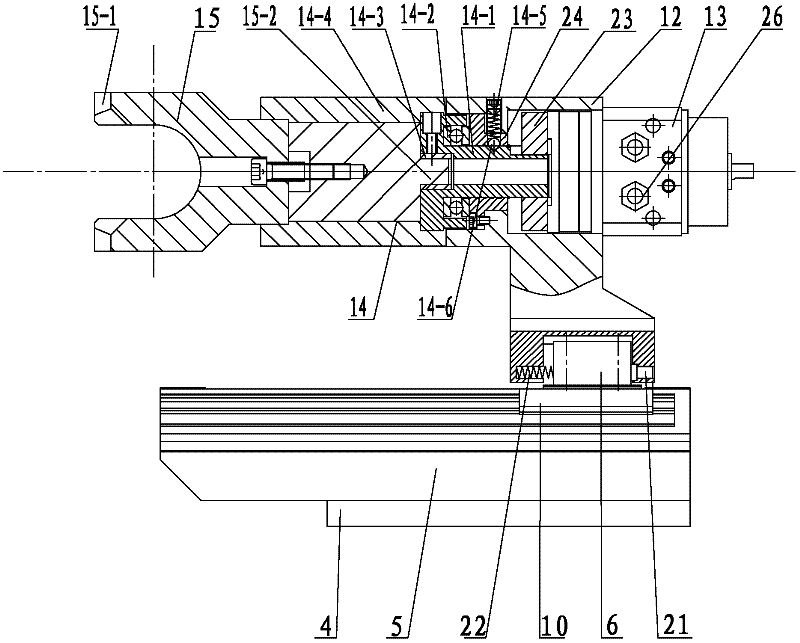

[0018] See Figure 1~6 As shown, the clamping device for photomask flushing of the present invention includes a workbench 1 and an opening and closing drive mechanism and an automatic turning mechanism installed on the workbench 1. The workbench 1 of the present invention is provided with an orifice 1-1 , the workbench 1 is arranged on the top of the cleaning chamber, and at the top of the cleaning chamber, the photomask 20 is grasped, turned over and placed by the clamping device of the present invention, and the cleaning liquid sprayed out by the nozzle is applied to both sides of the photomask 20 Clean up.

[0019] See Figure 1~4 As shown, the opening and closing drive mechanism of the present invention includes two guide rail seats 5 arranged diagonally along the workbench 1, a drive assembly and a synchronous assembly respectively installed on the two guide rail seats 5, and the drive assembly includes a cylinder 10, a linear guide rail 11 and a transition The slider 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com