One-step molding process for optical communication assembly seat

A forming process and one-time technology, which is applied in the field of one-time forming process of optical communication component seat, can solve the problems of difficult to meet market demand, low efficiency of machining method, low utilization rate of raw materials, etc., and achieve low production cost and good fluidity , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

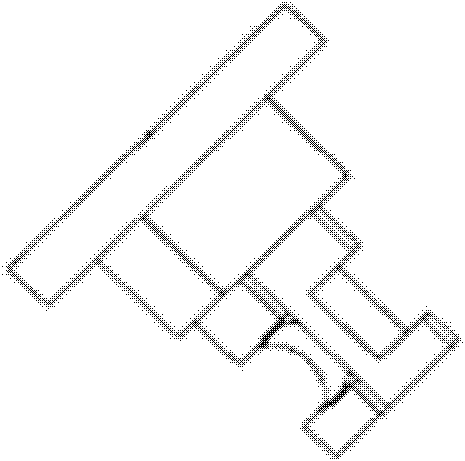

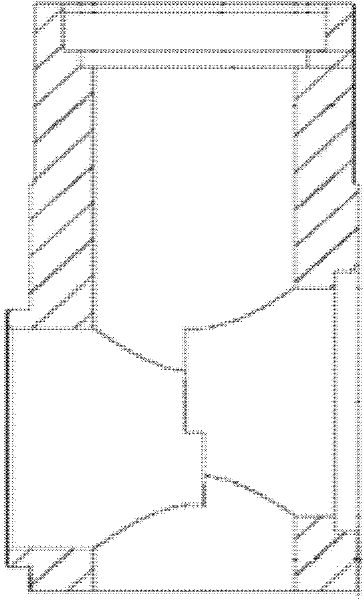

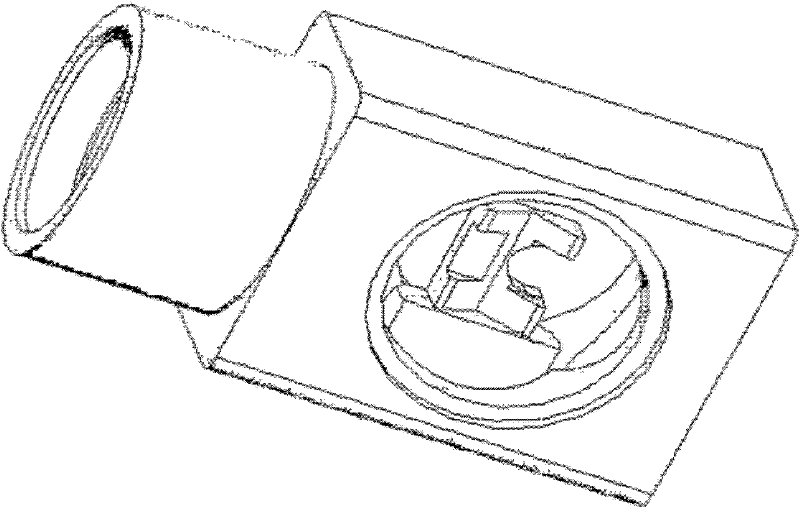

Image

Examples

Embodiment 1

[0024] The present invention takes the optical communication assembly seat as an example to introduce the present invention in detail, and its process is as follows:

[0025] Raw material preparation: the powder raw material used is 304 stainless steel aerosolized powder provided by Osprey Company of the United Kingdom;

[0026] Preparation of binder: by weight percentage, PW70%, PE20%, SA10% are placed in a blade mixer, and mixed for 1 hour at a temperature of 140 ° C;

[0027] Preparation of feeding materials: weigh the binder and 304 powder according to the volume ratio of 50:60, and carry out mixing. The mixing temperature is 130°C, the speed of the mixing machine is 40r / min, and the mixing time is 2h;

[0028] Injection molding: put the prepared feed into BOY50T injection molding machine, injection temperature is 165°C, injection pressure is 60MPa, mold temperature is 60°C, and the blank is injection-molded.

[0029] Blank treatment: first place the blank in a dichlorome...

Embodiment 2

[0032] The present invention takes the optical communication assembly seat as an example to introduce the present invention in detail, and its process is as follows:

[0033] Raw material preparation: The powder raw material used is the gas atomized powder of 304 stainless steel provided by the British Osprey company.

[0034] Preparation of binder: by weight percentage, PW70%, PE15%, SA15%, put in a blade mixer, mix at 150°C for 1.5 hours.

[0035] Preparation of feed: weigh the binder and 304 powder according to the volume ratio of 60:50, and mix them. The mixing temperature is 140° C., the kneading machine speed is 50 r / min, and the kneading time is 1.5 h.

[0036] Injection molding: put the prepared feed into BOY50T injection molding machine, injection temperature is 135°C, injection pressure is 80MPa, mold temperature is 50°C, and the blank is injection-molded.

[0037] Blank treatment: first place the blank in a dichloromethane solvent to dissolve the PE component; the...

Embodiment 3

[0040] The present invention takes the optical communication assembly seat as an example to introduce the present invention in detail, and its process is as follows:

[0041] Raw material preparation: The powder raw material used is the gas atomized powder of 304 stainless steel provided by the British Osprey company.

[0042] Preparation of binder: by weight percentage, PW70%, PE15%, SA10% were placed in a blade mixer, and mixed at a temperature of 160° C. for 2 hours.

[0043] Preparation of feed: Weigh the binder and 304 powder according to the volume ratio of 50:50, and then knead them. The mixing temperature is 150° C., the rotation speed of the kneader is 55 r / min, and the kneading time is 1.8 h.

[0044] Injection molding: put the prepared feed into BOY50T injection molding machine, injection temperature is 145°C, injection pressure is 100MPa, mold temperature is 40°C, and the blank is injection molded.

[0045] Blank treatment: first place the blank in a dichlorometh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com