Preparation process of special rubber powder for architectural coating

A preparation process and technology for architectural coatings, applied in the direction of starch derivative coatings, etc., can solve the problems of low reaction efficiency, long reaction time, and long production process, and achieve the effects of high transparency, short reaction time, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

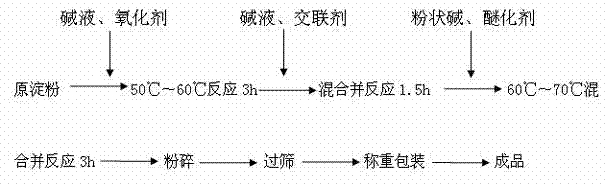

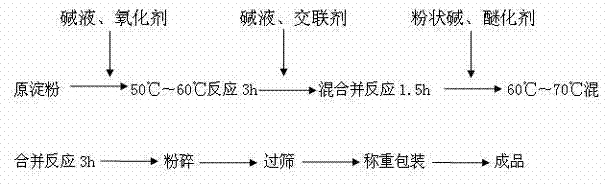

Method used

Image

Examples

Embodiment 1

[0060] (1) Oxidation reaction:

[0061] Put 1000kg of raw starch into the stainless steel reaction tank through the elevator, start the motor to stir, spray 10% NaOH solution into the starch through the spray system, adjust the pH to 10, after adjusting the pH, add 5Kg industrial H 2 o 2 The solution prepared with 60Kg of water is heated at the same time, the temperature is controlled at 50°C to 60°C, and the reaction is carried out at this temperature for 3 hours;

[0062] Hydrogen peroxide generates active oxygen under alkaline conditions, which can break and oxidize starch glycosidic bonds, reduce the instability of starch molecules, and introduce carbonyl and carboxyl groups on starch molecules to obtain oxidized starch.

[0063] (2), cross-linking reaction:

[0064] After the oxidation reaction is completed, adjust the pH value to 11.5 with NaOH solution, spray into a solution made of 0.04Kg epichlorohydrin and 8Kg industrial alcohol, and react for 2 hours at 50°C to 60...

Embodiment 2

[0069] (1) Oxidation reaction: Put 1000kg of raw starch into the stainless steel reaction tank through the elevator, start the motor to stir, spray 10% NaOH solution into the starch through the spray system, and adjust the pH to 8.5; adjust the pH After that, add 9Kg industrial H 2 o 2 And 60Kg water solution, turn on the oil pump to heat at the same time, control the temperature at 50℃~60℃, and react at this temperature for 2h;

[0070] (2) Cross-linking reaction: After the oxidation reaction is completed, adjust the pH value to 10 with NaOH solution, spray a solution made of 0.08Kg epichlorohydrin and 8Kg industrial alcohol, and react at 50°C to 60°C for 3 hours;

[0071] (3) Etherification reaction: After the cross-linking reaction is completed, adjust the temperature below 30°C, then put 104Kg powdered NaOH into the reaction tank, stir and mix for 30min, and then add 70Kg ClCH 2 The solution made of COOH and 60Kg industrial alcohol is sprayed into the reaction tank for r...

Embodiment 3

[0073] (1) Oxidation reaction: Put 1000kg of raw starch into the stainless steel reaction tank through the elevator, start the motor to stir, spray 10% NaOH solution into the starch through the spray system, and adjust the pH to 9; adjust the pH Finally, add 6Kg industrial H 2 o 2 And 65Kg water solution, turn on the oil pump to heat at the same time, control the temperature at 50 ℃ ~ 60 ℃, and react at this temperature for 2 hours;

[0074] (2) Crosslinking reaction: After the oxidation reaction is completed, adjust the pH value to 11 with NaOH solution, spray a solution made of 6Kg sodium trimetaphosphate and 10Kg water, and react at 50°C to 60°C for 3 hours;

[0075] (3) Etherification reaction: After the cross-linking reaction is completed, adjust the temperature below 30°C, then put 65kg of powdered NaOH into the reaction tank, stir and mix for 30min, and then add 70kg of ClCH 2 The solution made of COONa and 60kg of water was sprayed into the reaction tank for reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com