Vacuum sputtering UV-curable finish coat

A technology of vacuum sputtering and ultraviolet light, which is applied in the field of coatings, can solve the problems of poor chemical resistance, low production efficiency, and insufficient wear resistance, and achieve the effects of low volatility, beautiful appearance, and enhanced adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

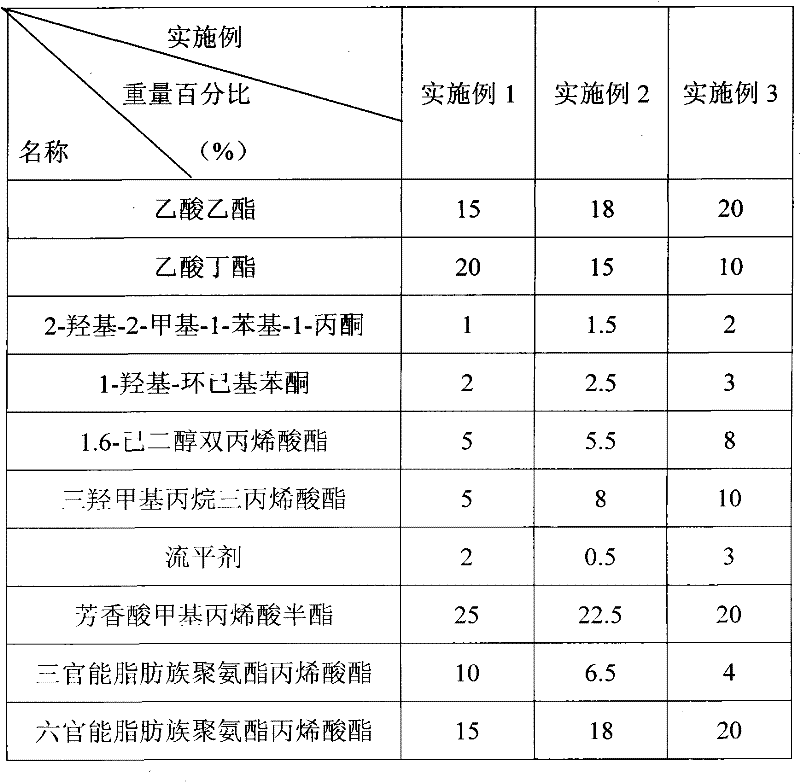

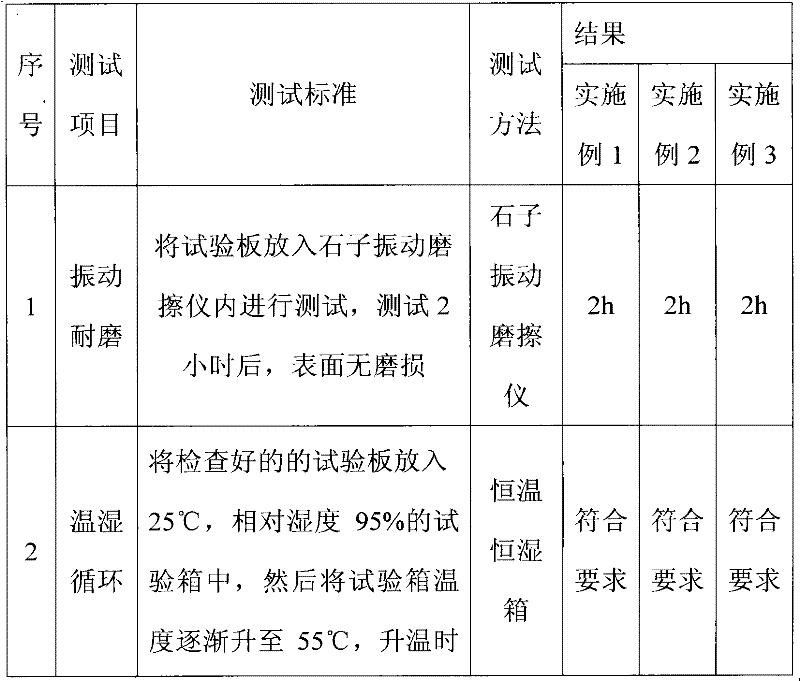

Embodiment 1

[0045] The preparation method of vacuum sputtering UV-curing topcoat comprises the following steps: (1) adding 15% of ethyl acetate, 20% of butyl acetate, 2-hydroxy-2-methyl- 1% of 1-phenyl-1-acetone, 2% of 1-hydroxy-cyclohexyl phenone, and then stirred for 10 minutes at 200 rpm with a dispersing mixer; (2) according to the above weight percentage, add 1, 5% of 6-hexanol diacrylate, 5% of trimethylolpropane triacrylate, and then stirred for 10 minutes at 300 rpm with a dispersing mixer; (3) according to the above weight percentage, add a leveling agent to the container Polyether-modified polysiloxane 2%, then use a dispersing mixer at 350 rpm for 10 minutes; (4) According to the above weight percentage, add 25% aromatic acid methacrylate half ester, trifunctional aliphatic 10% of aliphatic urethane acrylate and 15% of hexafunctional aliphatic urethane acrylate, and then stirred with a dispersing mixer at 700 rpm for 30 minutes; (5) 400-mesh filtration, packaging to obtain a fi...

Embodiment 2

[0047] The preparation method of vacuum sputtering UV-curable topcoat comprises the following steps: (1) adding 18% ethyl acetate, 15% butyl acetate, 2-hydroxy-2-methyl- 1-Phenyl-1-acetone 1.5%, 1-hydroxy-cyclohexyl phenone 2.5%, and then with a dispersing mixer at 250 rev / min, stirring for 8 minutes; (2) According to the above weight percentage, add 1, 5.5% of 6-hexanol diacrylate, 8% of trimethylolpropane triacrylate, and then stirred for 9 minutes at 400 rpm with a dispersing mixer; (3) according to the above weight percentage, add a leveling agent to the container 0.5% of polyether-modified polysiloxane, and then stirred at 400 rpm for 9 minutes with a dispersing mixer; (4) According to the above weight percentage, add 22.5% of aromatic acid methacrylate half ester, trifunctional aliphatic 6.5% of aliphatic urethane acrylate and 18% of hexafunctional aliphatic urethane acrylate, and then stirred with a dispersing mixer at 800 rpm for 28 minutes; (5) 450-mesh filtration and...

Embodiment 3

[0049]The preparation method of vacuum sputtering UV-curing topcoat comprises the following steps: (1) adding 20% ethyl acetate, 10% butyl acetate, 2-hydroxy-2-methyl- 1-Phenyl-1-acetone 2%, 1-hydroxy-cyclohexyl phenone 3%, then with a dispersing mixer at 300 rev / min, stirring for 5 minutes; (2) According to the above weight percentage, add 1, 8% of 6-hexanol diacrylate, 10% of trimethylolpropane triacrylate, and then stirred for 8 minutes at 500 rpm with a dispersing mixer; (3) according to the above weight percentage, add a leveling agent to the container Polyacrylate 3%, then use a dispersing mixer to stir at 400 rpm for 8 minutes; (4) According to the above weight percentage, add 20% aromatic acid methacrylate half ester, trifunctional aliphatic urethane acrylate 4 to the container %, 20% of hexafunctional aliphatic urethane acrylate, and then stirred at 900 rpm for 25 minutes with a dispersing mixer; (5) 500-mesh filtration and packaging to obtain the finished product. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com