Leachate guide and discharge device for garbage landfill gas collecting well

A technology for landfills and gas collection wells, applied in landfill technology, water supply devices, drainage structures, etc., can solve the problems of complex process, low degree of automation, and low gas collection efficiency of the gas collection system, and achieve improved collection Efficiency, improvement of automation, and cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

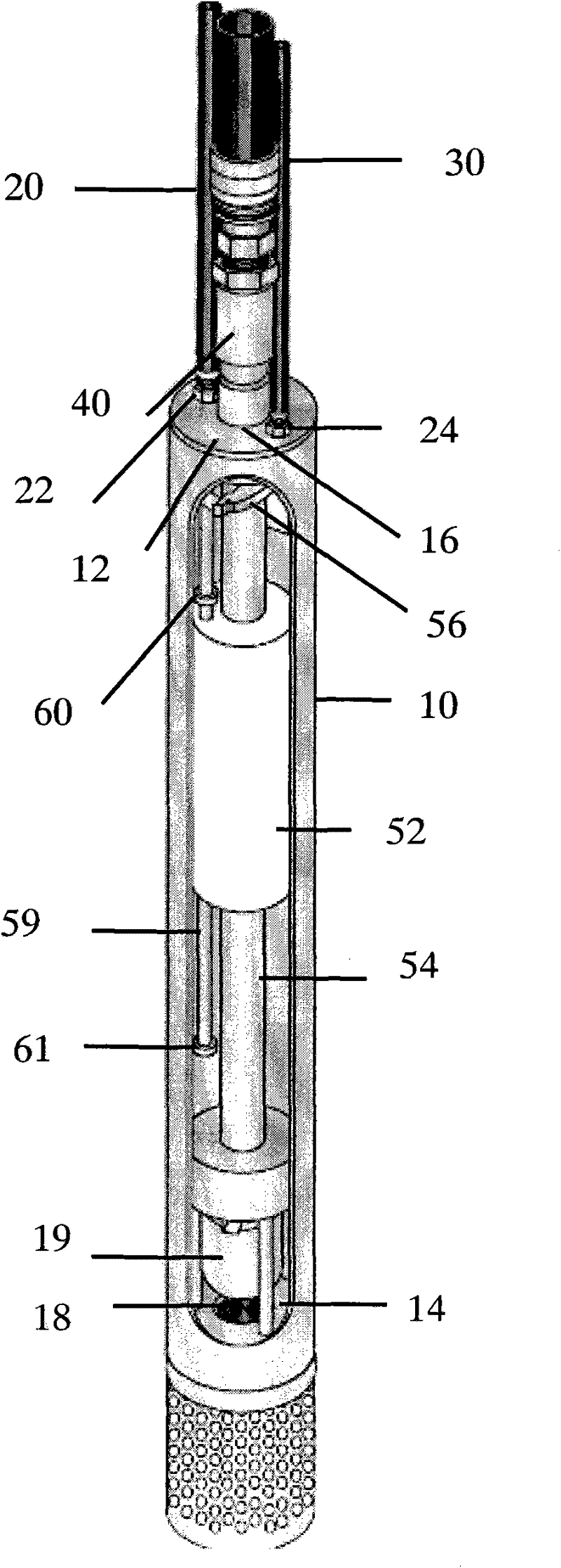

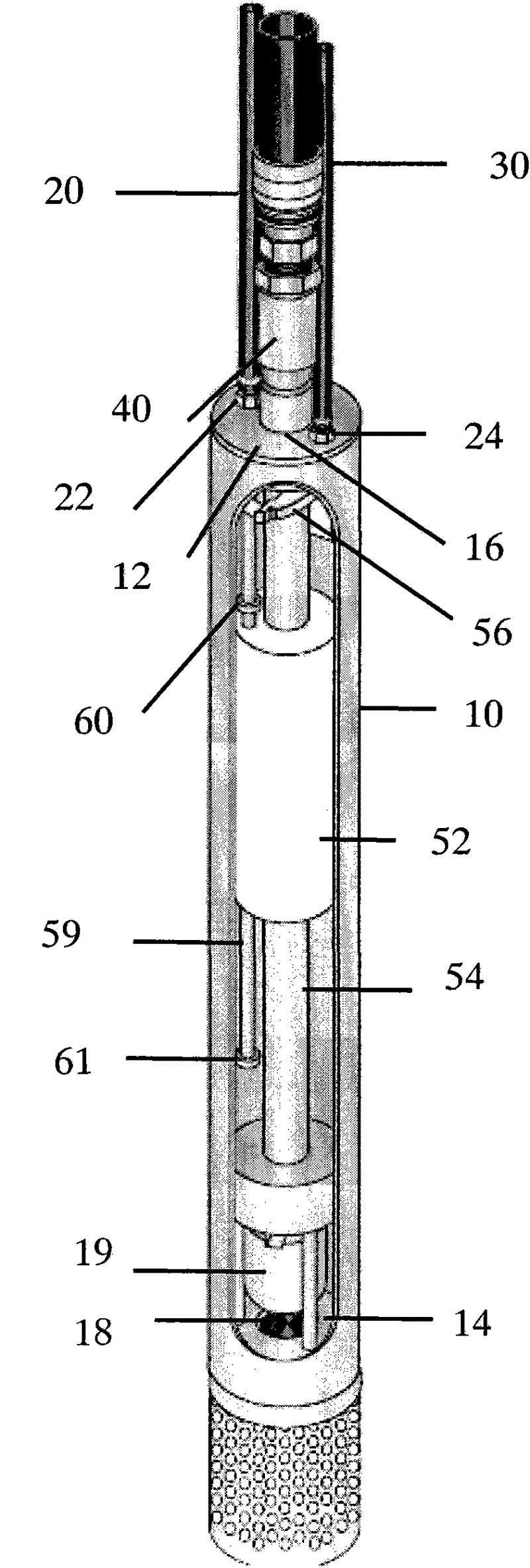

[0029] figure 1 It is a structural schematic diagram of a leachate drainage device used in a gas collection well of a landfill according to an embodiment of the present invention, and the device can be located in a gas collection well of a landfill. The water collecting pipe 10 has an upper top plate 12 and a lower bottom plate 14, the upper bottom plate 12 has a hole 16 approximately in the center, and the lower bottom plate 14 has a hole 18 equipped with a check valve 19 approximately in the center; compressed air pipe 20 , is connected with the intake valve 22 that penetrates the upper top plate 12; the exhaust pipe 30 is connected with the exhaust valve 24 that penetrates the upper top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com