Lithium ion battery, active cathode material and preparation methods thereof

A cathode active material, lithium-ion battery technology, applied in battery electrodes, electrolyte battery manufacturing, secondary batteries and other directions, can solve the problems of high interface impedance, poor electronic conductivity, etc., to achieve easy process, simple method, good conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Make 100 pieces of 423450A lithium-ion batteries, the specific preparation steps are as follows.

[0018] 1) Positive electrode ingredients.

[0019] Firstly, the positive electrode active material is prepared, the coating solution is mixed with the positive electrode active material by a spray dispersion method, the mixture is dried after washing, and then sintering heat treatment is carried out at 400-600° C. in an inert gas atmosphere. Specifically include the following steps:

[0020] 01) The positive electrode active material LiCoO with a particle size D50 of 9 μm to 20 μm 2 Put the particles into the spray fluidized bed dryer, turn on the induced draft fan and blower, observe the fluidization of the seed crystals in the fluidized bed, and adjust the air speed to ensure that the particles in the fluidized bed are well fluidized. Turn on the electric heater to heat the fluidized LiCoO 2 particles.

[0021] 02) Glucose solution with a mass specific concentration ...

Embodiment 2

[0051] Prepare 100 models of 423450A lithium-ion batteries. The difference between the preparation steps and Example 1 is that in step 1) positive electrode ingredients, in step 02) when preparing the positive electrode active material, a glucose solution with a mass ratio concentration of 20% and mass Al(OH) with a specific concentration of 10% 3 The solutions were mixed to make a coating solution, and other steps and formulations were the same as in Example 1.

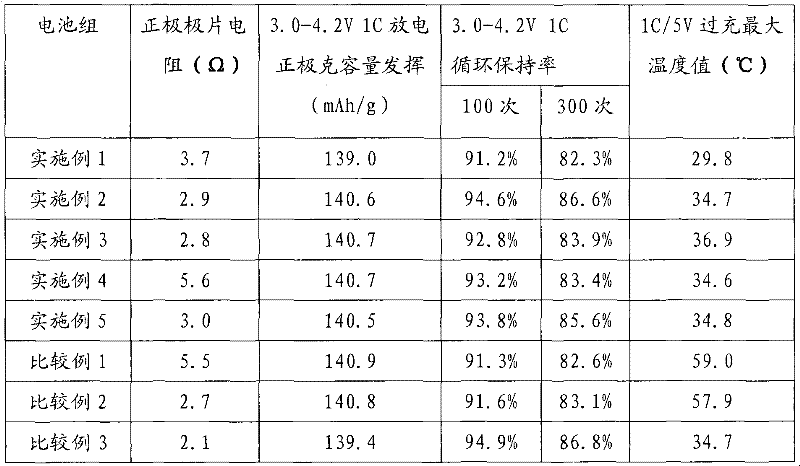

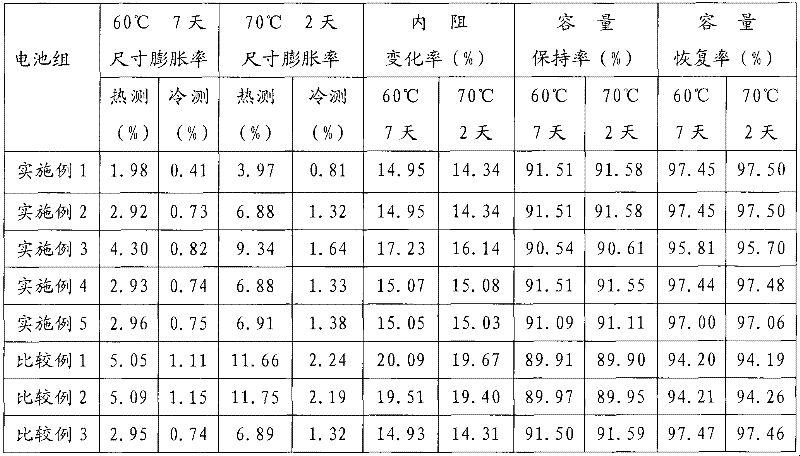

[0052] The charging and discharging, cycle, overcharge test and high temperature storage performance test conditions and methods of the battery are the same as in Example 1. The test results are shown in Table 1 and Table 2.

Embodiment 3

[0054] Prepare 100 models of 423450A lithium-ion batteries. The difference between the preparation steps and Example 1 is that in step 1) positive electrode ingredients, in step 02) when preparing the positive electrode active material, a glucose solution with a mass ratio concentration of 20% and mass Al(OH) with a specific concentration of 5% 3 The solutions were mixed to make a coating solution, and other steps and formulations were the same as in Example 1.

[0055] The charging and discharging, cycle, overcharge test and high temperature storage performance test conditions and methods of the battery are the same as in Example 1. The test results are shown in Table 1 and Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com