Method for preparing anisotropic bonded rare-earth permanent magnet

A rare earth permanent magnet, anisotropic technology, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problems of material performance decline, low strength, difficult orientation, etc., to improve magnetic properties, good orientation, and market competition. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

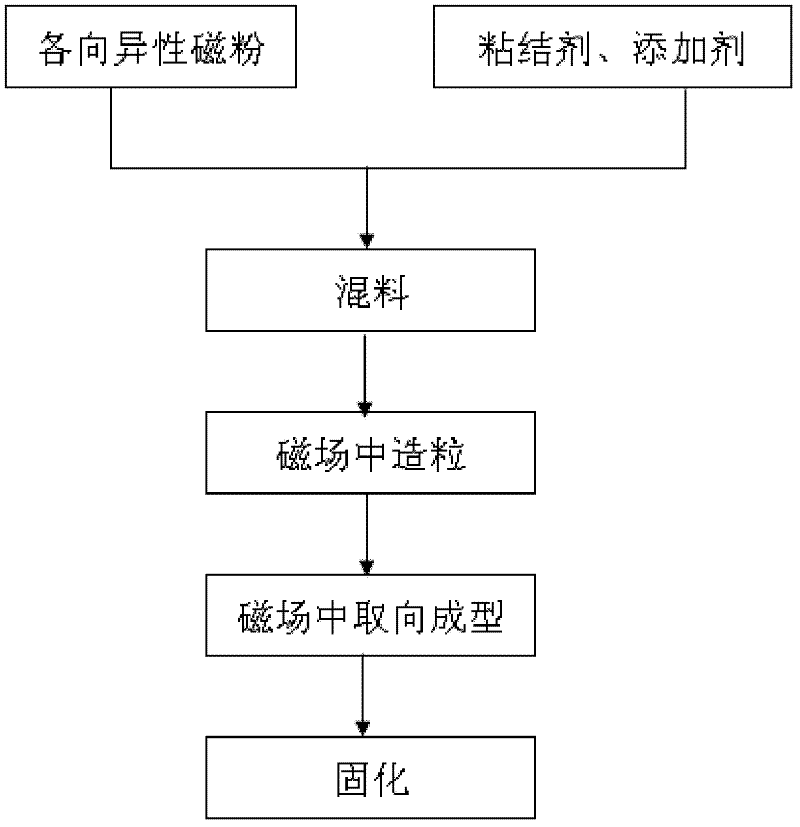

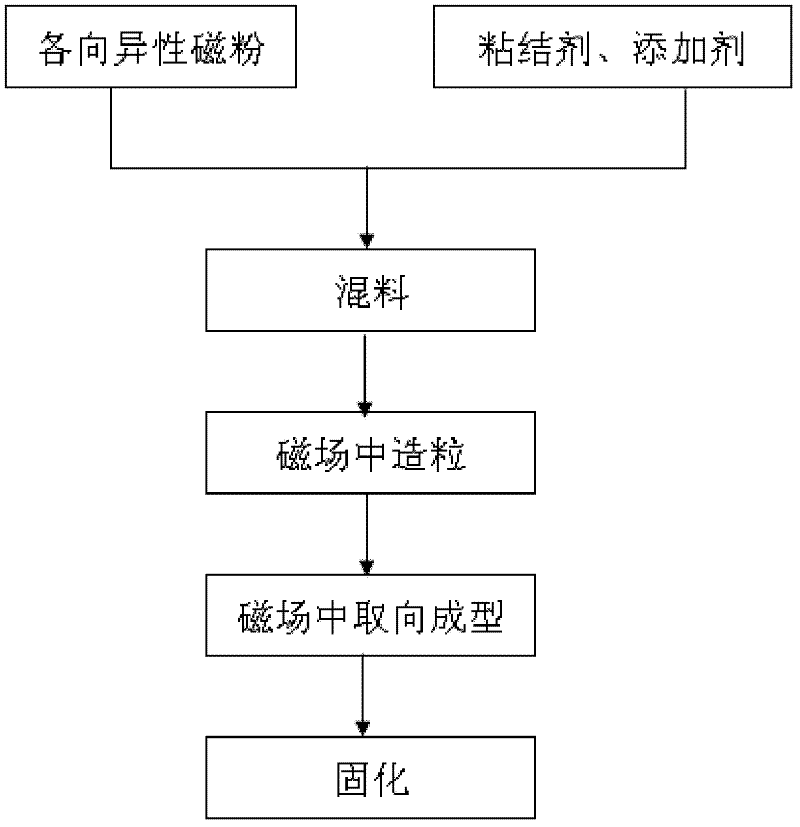

Method used

Image

Examples

Embodiment 1

[0040] Take out the anisotropic NdFeB magnetic powder 96.9% (mass percentage) of crossing 100 mesh sieves (the particle size of anisotropic rare earth permanent magnet magnetic powder is all crossing 100 mesh sieves in the following examples), KH-550 silane coupling agent is 1% (mass percentage), binder is 1.9% (mass percentage); 0.2% (mass percentage) of zinc stearate is for use. First, add the anisotropic NdFeB magnetic powder in the above ratio into the acetone solution dissolved in the KH-550 silane coupling agent in the above ratio, stir, and when the liquid content of the acetone solution is lower than 8%, add it into the dissolved In the acetone solution of the binder of the above ratio, stir, and when the liquid content of the acetone solution is lower than 8%, place the magnetic powder in a 0.5T magnetic field for stirring and drying, and when the liquid content of the magnetic powder reaches 5%, add Zinc stearate 0.2% of the above ratio, continue to stir until the ma...

Embodiment 2

[0042]Take out 98% (mass percentage) of the anisotropic NdFeB magnetic powder, 1.9% (mass percentage) of the binder, and 0.1% (mass percentage) of zinc stearate for use. First add the anisotropic NdFeB magnetic powder in the above ratio into the acetone solution in which the binder in the above ratio is dissolved, and stir. After the liquid content of the acetone solution is lower than 10%, place the magnetic powder in a 1T magnetic field for stirring Drying, when the liquid content of the magnetic powder is about to reach the predetermined target, add the zinc stearate in the above ratio, continue stirring until the magnetic powder reaches the expected liquid content of 5%, take out the magnetic powder, and sieve. Put the mixed magnetic powder into the cavity of the mold, and carry out orientation pressing in a magnetic field forming press with an orientation magnetic field of 1.7T and a forming pressure of 900 MPa, then demagnetize and demould to complete the forming of the m...

Embodiment 3

[0044] Take out anisotropic NdFeB magnetic powder 96.9% (mass percentage), KH-550 silane coupling agent is 1% (mass percentage), and binding agent is 1.9% (mass percentage); Zinc stearate 0.2% (mass percentage) )stand-by. Add the anisotropic NdFeB magnetic powder in the above ratio into the absolute ethanol solution dissolved in the KH-550 silane coupling agent in the above ratio, stir, and after the absolute ethanol is dried, add it into the viscose solution in the above ratio Stir in the acetone solution of the binder. After the liquid content of the acetone solution is lower than 15%, place the magnetic powder in a 0.005T magnetic field for stirring and drying. When the liquid content of the magnetic powder is about to reach the predetermined target, add the above-mentioned proportion of Zinc stearate, continue to stir until the magnetic powder reaches the expected 6% liquid content, take out the magnetic powder, and sieve. Put the mixed magnetic powder into the cavity of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com