Special-purposed cellular composite material used for small unmanned air vehicle

A technology for small unmanned aerial vehicles and composite materials, applied in the aviation field, can solve problems such as undiscovered public documents, and achieve the effects of small thermal expansion and contraction deformation, high surface flatness, and high connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail through specific embodiments below in conjunction with the accompanying drawings. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

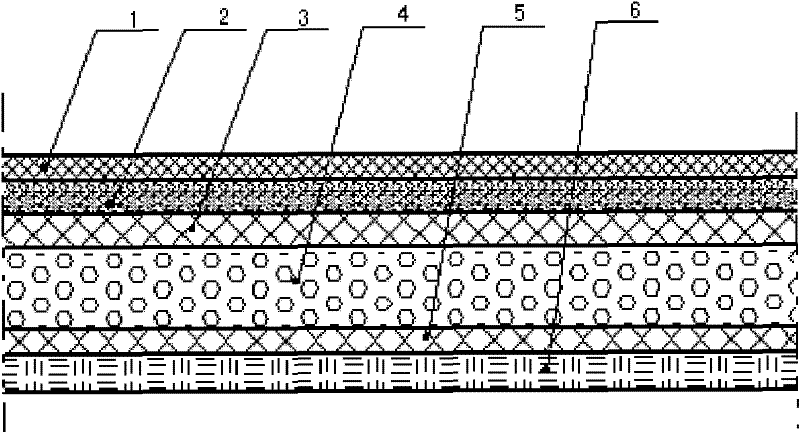

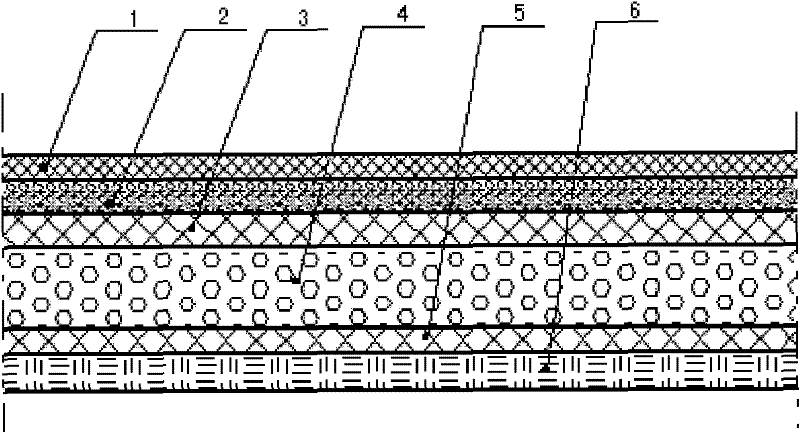

[0020] A special honeycomb composite material for small drones, see figure 1 , a layered composite structure made of panels and honeycomb interlayers bonded by adhesives. Among them, the panel includes: the outer panel is composed of epoxy varnish 1, topcoat 2, and outer glass fiber layer 3, the inner panel is composed of inner glass fiber layer 5, carbon fiber mixed cloth layer 6, and the honeycomb interlayer 4 is fixed on the outer panel. Between the outer glass fiber layer of the inner panel and the inner glass fiber layer of the inner panel. The cross-sectional structure of the composite material is as follows from inside to outside: carbon fiber mixed cloth layer, inner glass fiber layer, honeycomb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com