Instantaneous high temperature resistant intelligent fire-resistant heat-insulating composite fabric structure

A high temperature resistant and intelligent technology, applied in the direction of synthetic resin layered products, layered products, metal layered products, etc., can solve the problems of reducing efficiency, reducing heat and moisture transfer performance, physiological heat load, etc., to improve heat insulation performance, Excellent waterproof and breathable performance, excellent heat insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Such as Figure 4 As shown, the basalt fiber / carbon fiber cloth of the fireproof outer layer 1, the shape memory alloy fiber of the heat insulation layer 2, the waterproof breathable layer 3, and the outlast acrylic fiber / cotton cloth of the comfort layer 4 are combined in sequence, and the U-shaped shape memory alloy fiber and The polytetrafluoroethylene film composite cloth is set between the basalt fiber / carbon fiber cloth and outlast acrylic fiber / cotton cloth layers. The arch of the U-shaped shape memory alloy fiber is fixed at a certain position on the basalt fiber / carbon fiber cloth, and this position corresponds to the interweaving part of the carbon fiber. The foot of the U-shaped shape memory alloy fiber is semi-fixed on the polytetrafluoroethylene film composite cloth with a floating thread, and at the same time, a thermal insulation gasket is added to the corresponding position of the polytetrafluoroethylene film composite cloth.

Embodiment 2

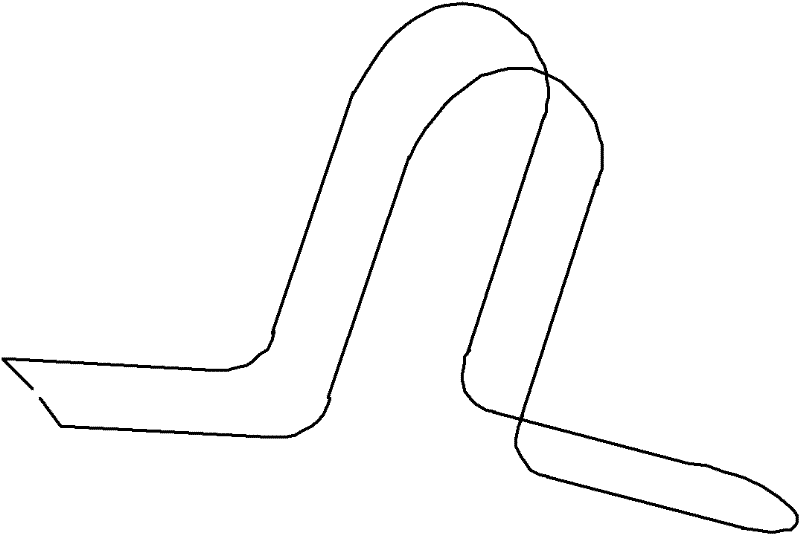

[0028] Such as Figure 5 As shown, the basalt fiber / carbon fiber cloth of the fireproof outer layer 1, the shape memory alloy fiber of the heat insulation layer 2, the waterproof breathable layer 3, and the outlast acrylic fiber / cotton cloth of the comfort layer 4 are combined in sequence, and the U-shaped shape memory alloy fiber and The polytetrafluoroethylene film composite cloth is set between the basalt fiber / carbon fiber cloth and outlast acrylic fiber / cotton cloth layers. When the S-shaped shape memory alloy fiber is excited, fix the corresponding position of its peak to the corresponding position on the basalt fiber / carbon fiber cloth, which corresponds to the interweaving of carbon fiber; and fix the corresponding position of the wave trough to the outlast acrylic fiber / cotton cloth At the same time, add a thermal insulation gasket to the corresponding position of the polytetrafluoroethylene film composite cloth.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com