Red luminous paint

A technology of red luminescent and luminescent materials, applied in luminescent coatings, polyester coatings, epoxy resin coatings, etc., can solve the problem of high corresponding temperature measurement temperature, achieve simple methods, improve temperature measurement accuracy, and reduce errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

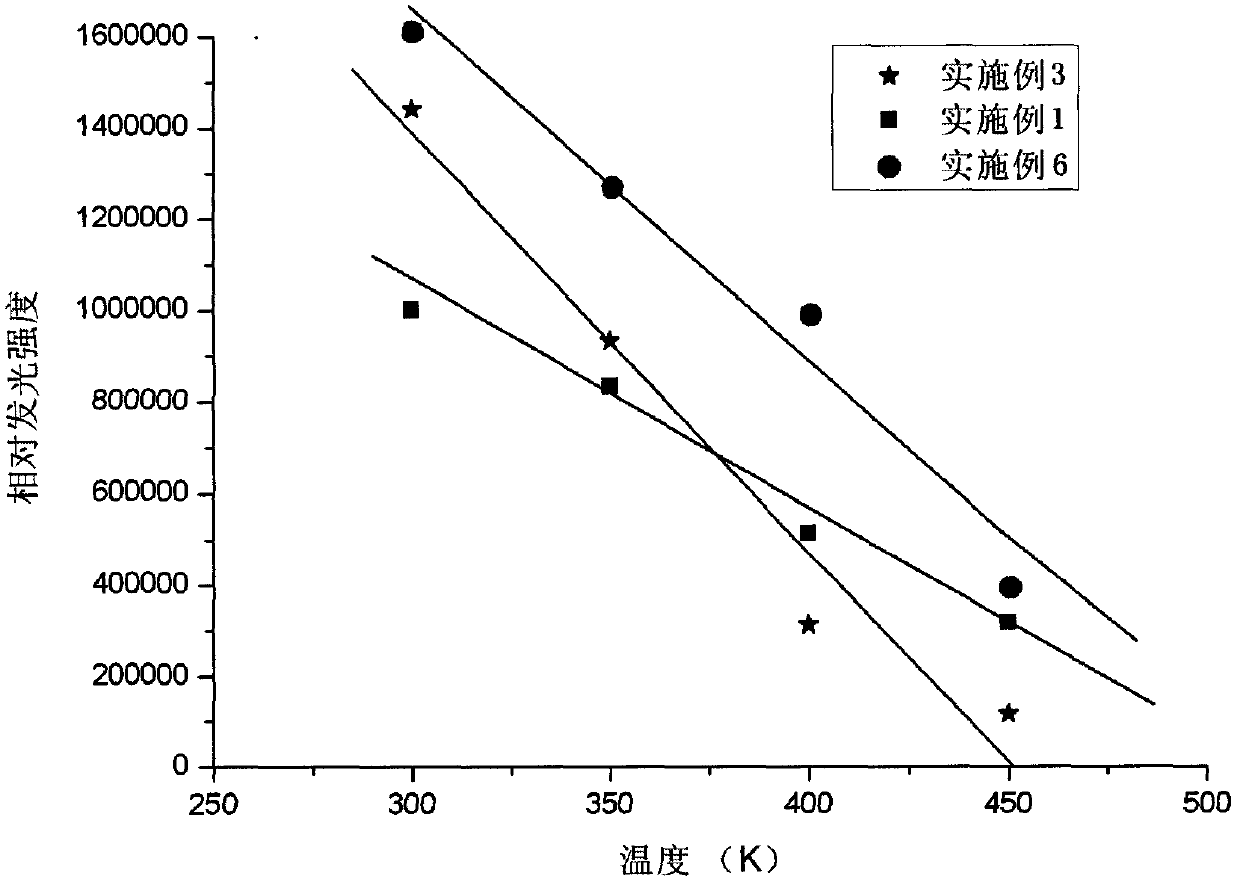

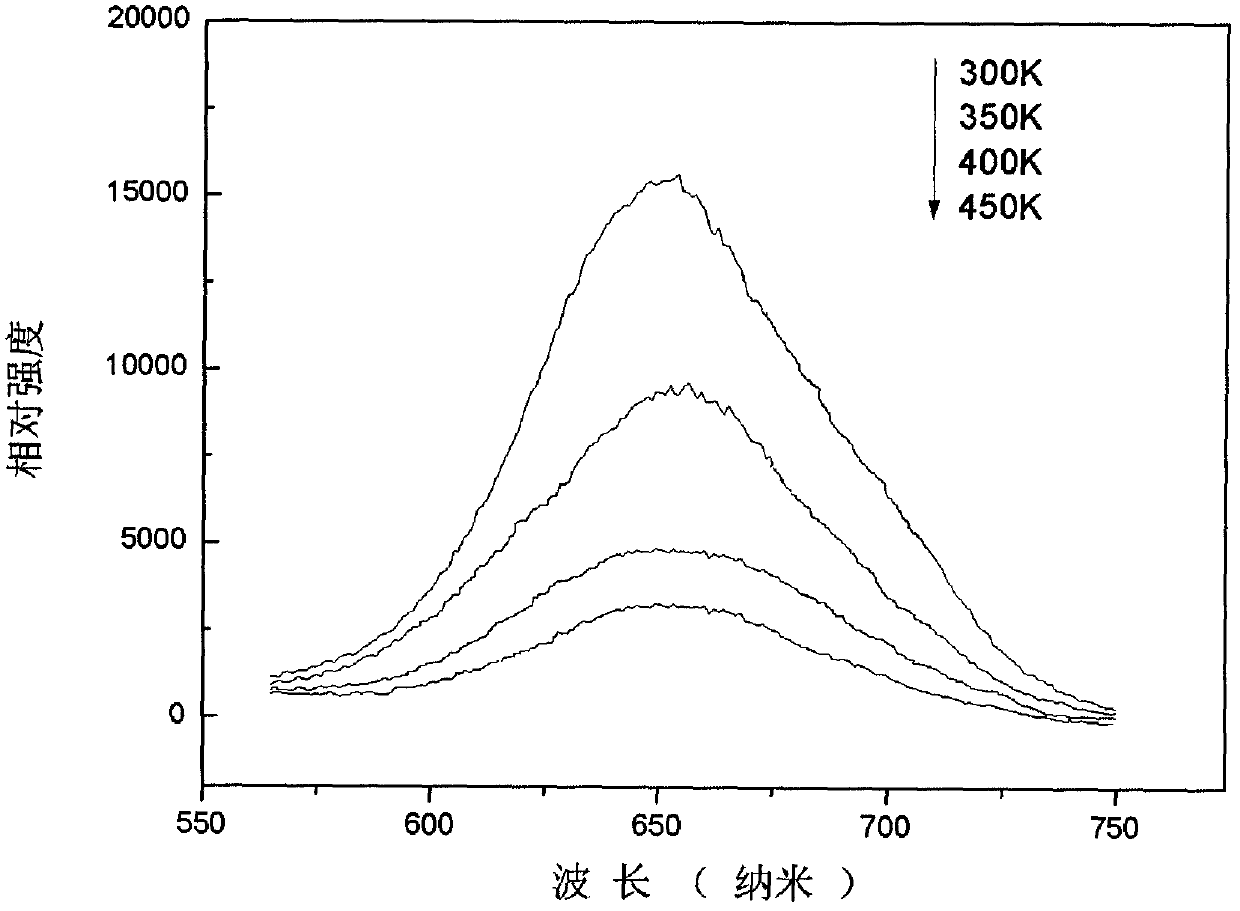

[0027] Specific examples are shown in the following table:

[0028]

[0029]

[0030] Only take Example 3 as an example to briefly describe the preparation process of the present invention, and the principles of the preparation process of other embodiments are the same.

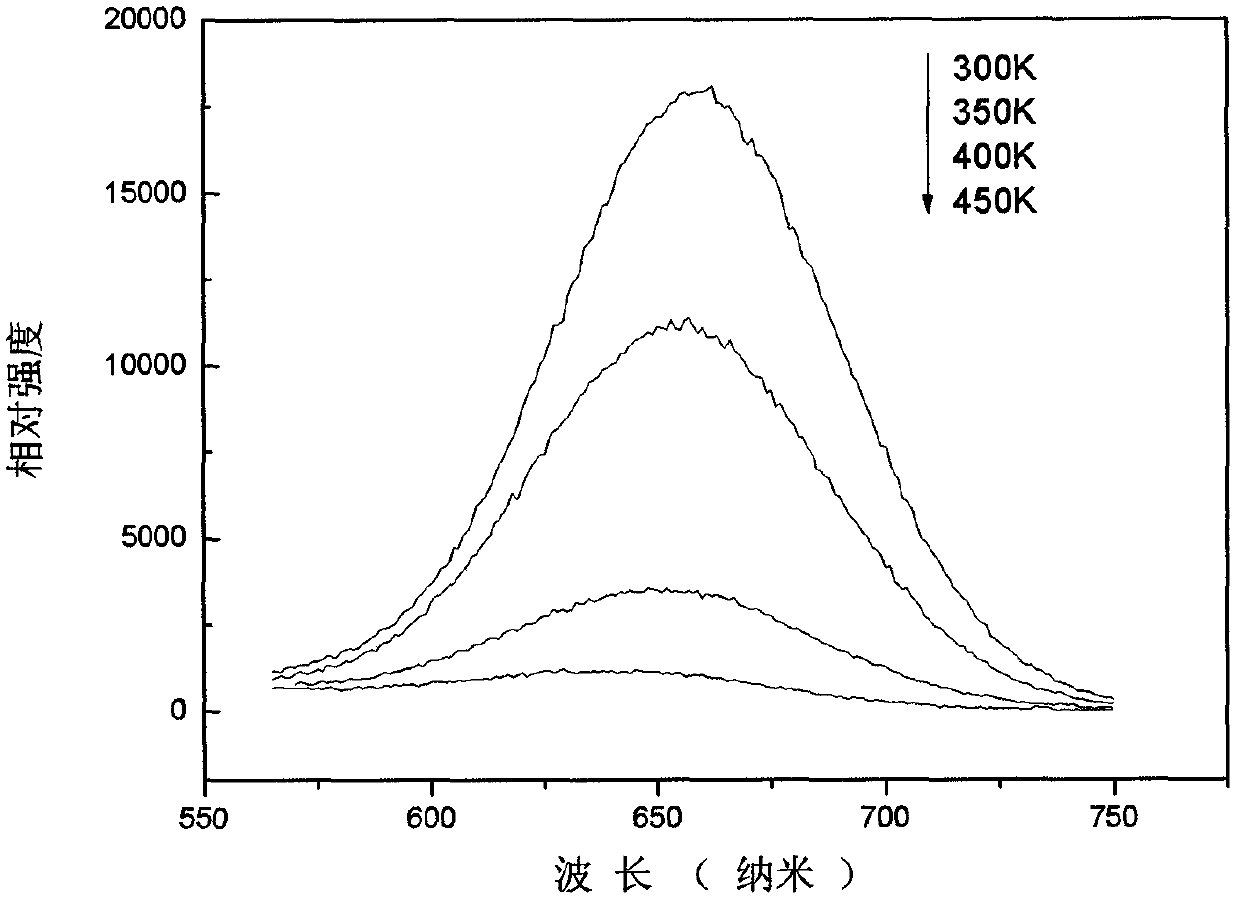

[0031] (1) The chemical formula prepared by traditional high-temperature solid phase method is: Ba 2 ZnS 3 :aEu 2+ (a=0.05) Luminescent material.

[0032] The raw materials are barium oxide, zinc oxide, europium trioxide and sulfur. Weigh the raw materials according to the stoichiometric ratio, grind and mix them evenly, burn the raw materials in a closed crucible at 900-1200°C for 1-20 hours, and then take them out of the furnace to cool to obtain the blocky red luminescent material Ba 2 ZnS 3 :0.05Eu 2+ .

[0033] (2) The bulk red luminescent material Ba 2 ZnS 3 :aEu 2+ After being roughly crushed by a jaw crusher, it is ground into a fine powder by a ball mill, passed through a 250-mesh sie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com