Cast steel matrix for process for preparing forging mould through double-layer build-up welding and preparation method thereof

A process and technology for casting steel, applied in the field of cast steel matrix and its preparation, can solve the problems of easy cracking of the surfacing layer, and achieve the effects of saving forging process, good weldability and excellent welding performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

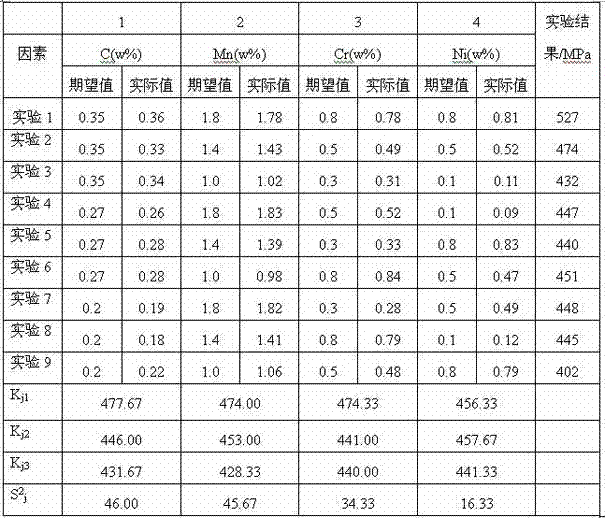

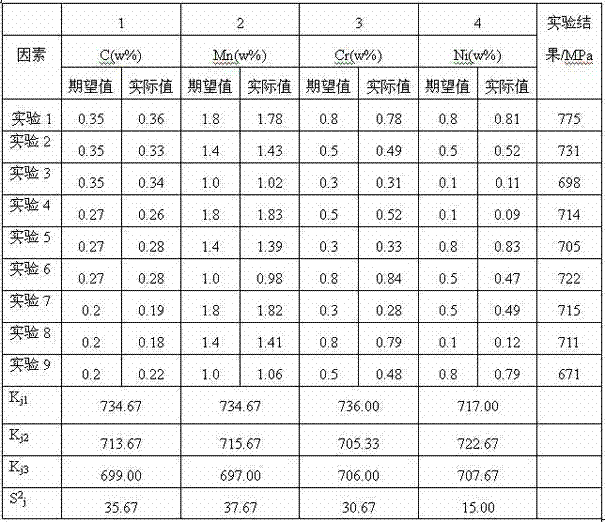

[0025] The present invention will be further verified and illustrated below in conjunction with specific experiments.

[0026] In order to verify the effect of the present invention, the applicant has carried out an orthogonal experiment. During the experiment, in the formula of the matrix material of the present invention, the specific proportions of C, Mn, Cr, and Ni four elements that play a major role in the performance of the material are selected, and the orthogonal experiment is adopted. For verification, the process is to obtain the cast steel matrix by normalizing and then tempering, wherein the normalizing temperature is 980-1020°C; the tempering temperature is 550-600°C, and the performance parameters such as the strength of the cast steel matrix obtained by testing , and then adopt the double-layer surfacing welding preparation forging die process described in the background technology to surfacing a transition layer on the surface of the cast steel substrate, and d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com