Method for preparing YBCO (Yttrium Barium Copper Oxide) coating conductor barrier layer

A technology for coating conductors and barrier layers, applied in the field of preparation of barrier layers in second-generation high-temperature superconducting tapes, can solve the problem of high cost of barrier layers, and achieve the effects of small surface roughness, high deposition rate and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Weigh 0.1 mol of aluminum isopropoxide, and dissolve aluminum isopropoxide in 135 mL of deionized water to prepare a solution.

[0020] (2) stirring the solution prepared in step (1) by a magnetic stirrer at 80° C. for 1 h;

[0021] (3) adding hydrochloric acid to the solution prepared in the above step (2), adjusting the pH value of the solution to 2;

[0022] (4) Stir the solution prepared in the above step (3) at 80°C for 4 hours with a magnetic stirrer to obtain a transparent Al 2 o 3 gel.

[0023] (5) the Al prepared in step (4) 2 o 3 The gel was spin-coated on the nickel-based alloy substrate at a speed of 5000 rpm, and the spin-coating time was 0.5 min;

[0024] (6) Place the film-coated substrate in step (5) in a high-temperature tubular quartz furnace, feed 500 sccm argon into the reaction chamber, raise the temperature from room temperature to 300° C. at a rate of 5° C. / h, and Keep warm for 5h, then cool the sample to room temperature with the furnac...

Embodiment 2

[0026] (1) Weigh 0.1 mol of aluminum isopropoxide, and dissolve aluminum isopropoxide in 200 mL of deionized water to prepare a solution.

[0027] (2) Stir the solution prepared in step (1) by a magnetic stirrer at 85° C. for 2 h;

[0028] (3) adding hydrochloric acid to the solution prepared in the above step (2), adjusting the pH value of the solution to 3;

[0029] (4) Stir the solution prepared in the above step (3) at 85°C for 6h with a magnetic stirrer to obtain a transparent Al 2 o 3 gel.

[0030] (5) the Al prepared in step (4) 2 o 3 The gel was spin-coated on the nickel-based alloy substrate at a speed of 5000 rpm, and the spin-coating time was 1 min;

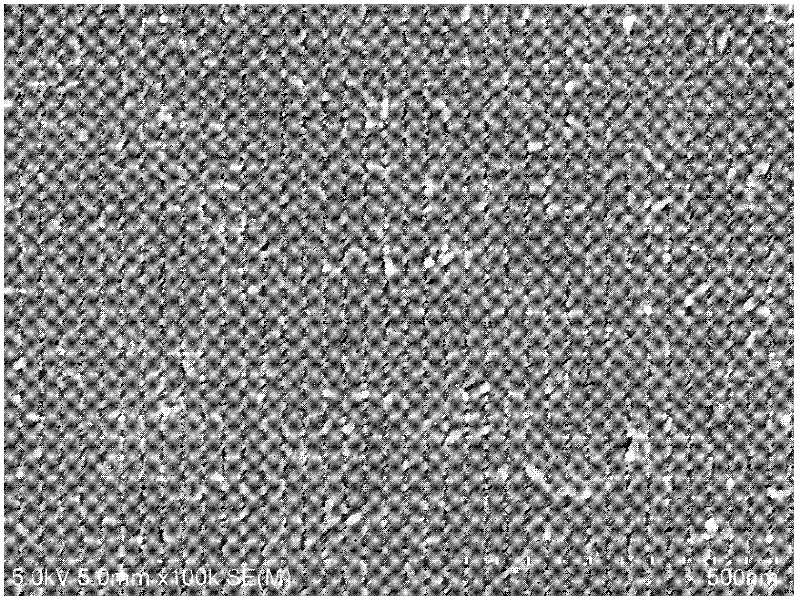

[0031] (6) Place the film-coated substrate in step (5) in a high-temperature tubular quartz furnace, feed 500 sccm argon into the reaction chamber, heat up to 400°C from room temperature at a rate of 5°C / h, and Keep warm for 10h, then cool the sample to room temperature with the furnace. The surface morphology o...

Embodiment 3

[0033] (1) Weigh 0.1 mol of aluminum isopropoxide, and dissolve aluminum isopropoxide in 270 mL of deionized water to form a solution;

[0034] (2) Stir the solution prepared in step (1) for 3 h with a magnetic stirrer at 90° C.;

[0035] (3) adding hydrochloric acid to the solution prepared in the above step (2), adjusting the pH value of the solution to 4;

[0036] (4) Stir the solution prepared in the above step (3) at 90°C for 8 hours with a magnetic stirrer to obtain a transparent Al 2 o 3 gel.

[0037] (5) the Al prepared in step (4) 2 o 3 The gel was spin-coated on the nickel-based alloy substrate at a speed of 5000 rpm, and the spin-coating time was 1.5 min;

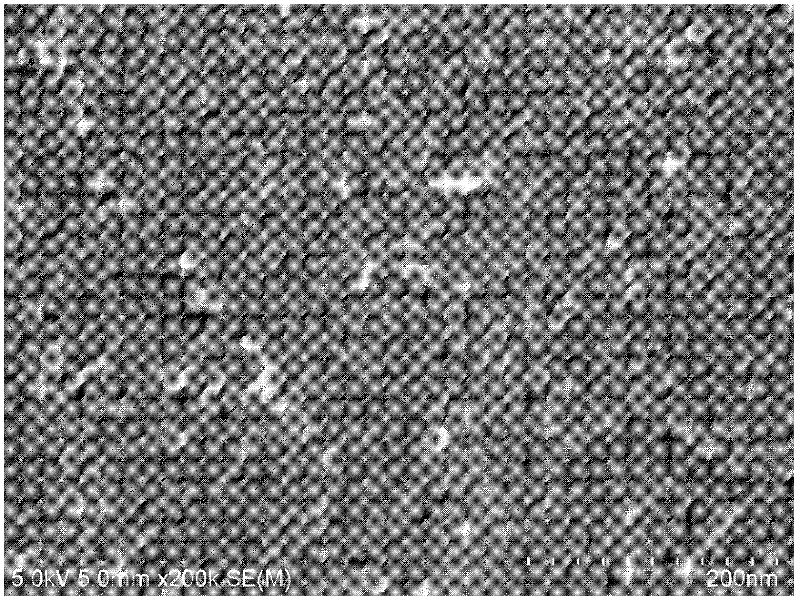

[0038] (6) Place the film-coated substrate in step (5) in a high-temperature tubular quartz furnace, feed 500 sccm of argon into the reaction chamber, heat up to 500°C from room temperature at a rate of 5°C / h and keep it warm 10h, then the sample was cooled to room temperature with the furnace. The surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com