Installation method of heating belt

An installation method and heating cable technology are applied in the direction of heating elements, heating element shapes, ohmic resistance heating parts, etc., which can solve problems such as the failure of the monitoring system of the heating cable, no waterproof measures for the insulation layer, and shortened service life of the heating cable. Achieve the effects of improving heat transfer efficiency and heat transfer stability, preventing heat transfer mud loss, and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

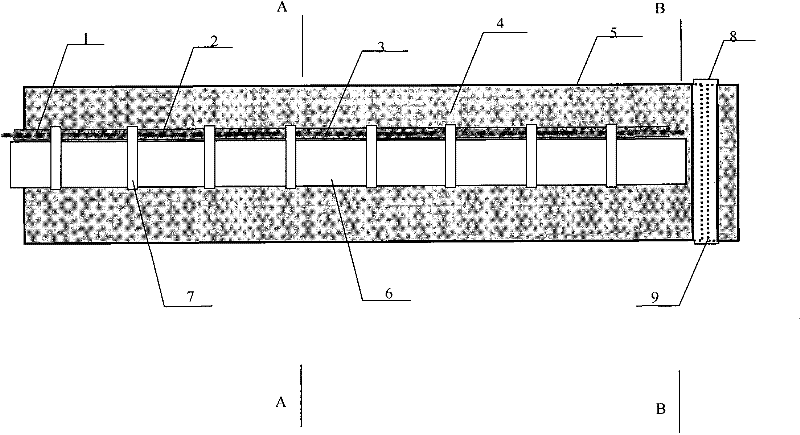

[0042] The model of the heating cable (3) is B / 1H00197SB / 120m / 6156W / 380V, which means that the cable structure is B, the number of heating cores is 1, the voltage level is 600V, the cable resistance is 0.197Ω / m, the sheath material is stainless steel, and heating resistance wire Material code B, cable length 120m, cable power 6156W, rated voltage 380V.

[0043] The installation method is as follows:

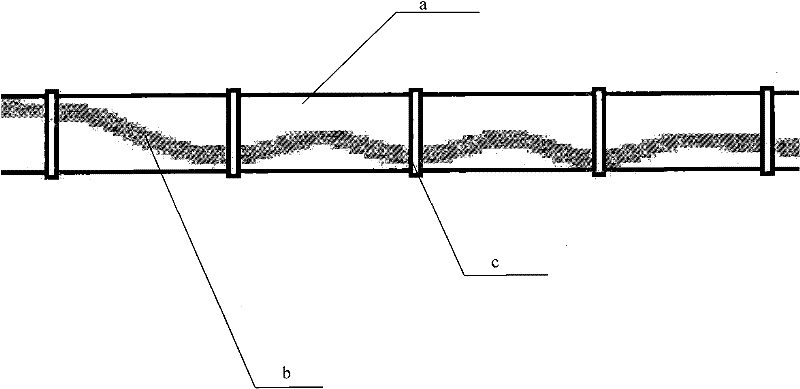

[0044]1. Remove burrs and rust spots on the surface of the pipe 6 to make the surface clean and smooth to prevent poor contact between the heating cable 3 and the pipe 6 and affect the heat transfer effect;

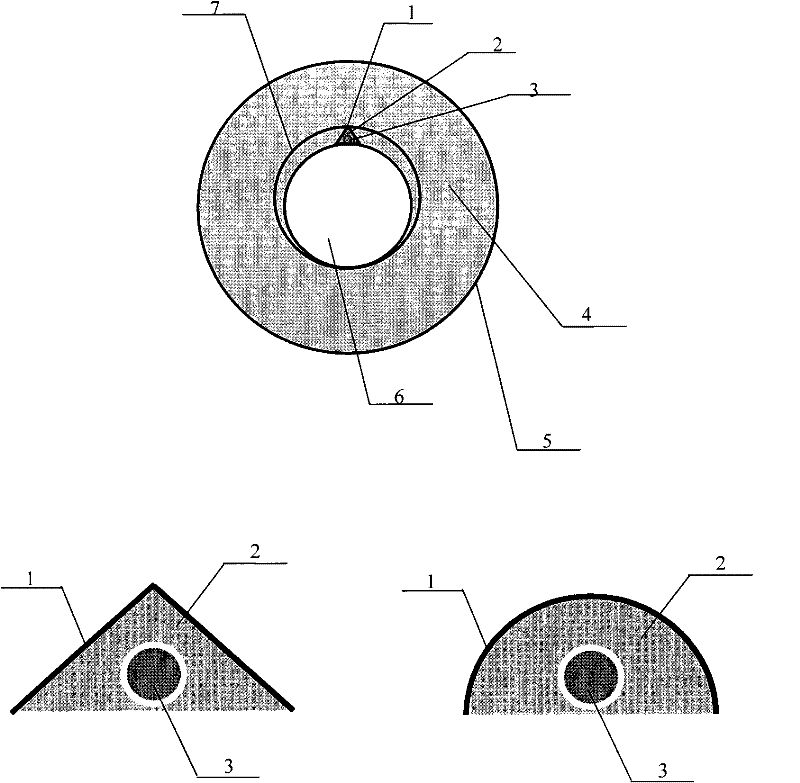

[0045] 2. Make a total of 158 protective tubes 1, using 0.3mm thick aluminum skin. The length of a single protective tube 1 is 2000mm, the cross-sectional shape is triangular, the angle of the apex of the triangle is 90 degrees, and the waist length of the triangle is 20mm. Remove the burrs around the protective tube 1 with a fine file to prevent scratching the outer metal ...

Embodiment 2

[0054] The model of heating cable 3 is B / 1H00328SB / 112m / 3934W / 380V, and its meaning is similar to that of embodiment 1, except that the resistance, length and power of heating cable 3 are different.

[0055] The installation method is as follows:

[0056] 1. Remove burrs and rust spots on the surface of the container shell 6 to make the surface clean and smooth, so as to prevent poor contact between the heating cable 3 and the container shell 6 and affect the heat transfer effect;

[0057] 2. Make a total of 6 protective tubes 1, using 0.2mm thick aluminum skin. The length of a single protective tube 1 is 2000mm, its cross-sectional shape is semicircular, and its diameter is 50mm. Use a fine file to remove the burrs around the protective tube 1 to prevent scratching the surface metal sheath of the heating cable 3 during construction;

[0058] 3. Lay the heating cable (3) along the container shell 6, and temporarily fix it with flexible cloth every 5 meters. When the heating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com