Heat exchanger structure and isothermal compression or expansion chamber

A technology of expansion cavity and heat engine, applied in the direction of moving duct heat exchanger, heat exchange equipment, indirect heat exchanger, etc., can solve the difference of heat exchange temperature, can not realize isothermal compression and expansion, low heat pump cycle efficiency, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

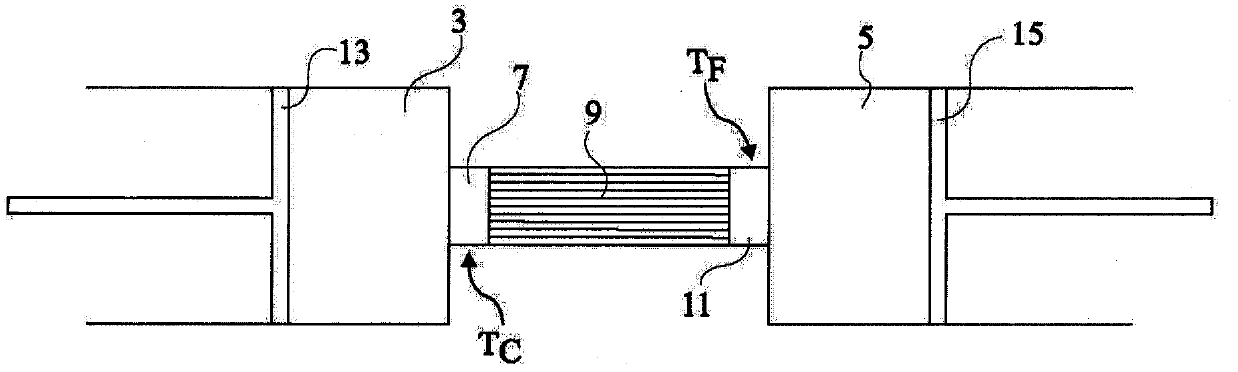

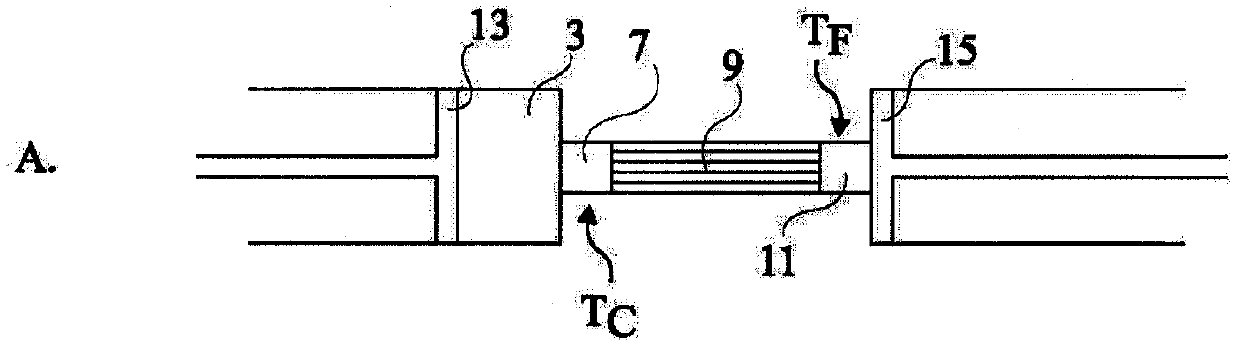

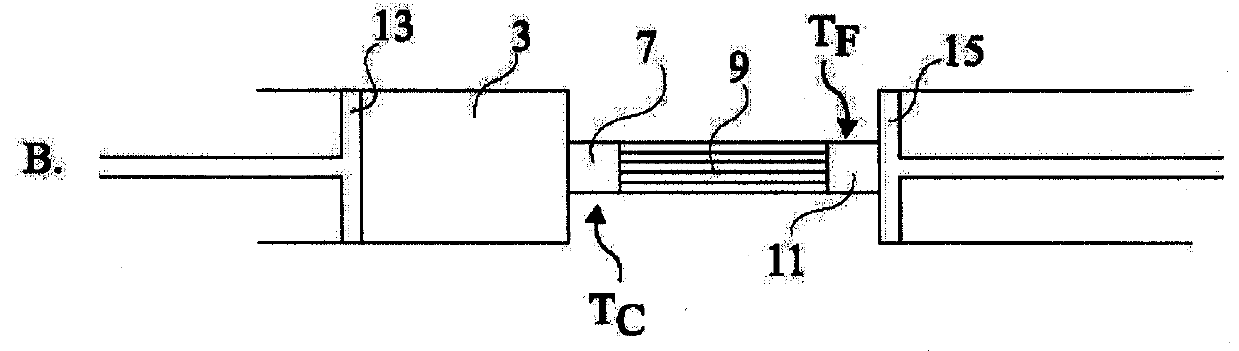

[0041] Embodiments of the present invention first provide for placing the heat exchanger directly in the compression and expansion chambers. It further provides formed compression and expansion chambers in which said exchanger comprises a number of parts forming partitions in said chambers. Such partitions extend from two opposing walls of the chamber and are staggered as the volume of the chamber decreases.

[0042] Figure 3A to Figure 3C The compression chamber or expansion chamber is shown in longitudinal section, as described above, forming part of, for example, a Stirling engine. These figures show different states in isothermal expansion.

[0043] exist Figure 3AIn the cylinder, a chamber 21 is formed in the cylinder and delimited by two walls 23 and 25 that are movable relative to each other in the cylinder. The example shown assumes a movable wall 23 associated with a piston shaft 27 and a fixed wall 25 fixed relative to a heat accumulator 29 (not detailed). It ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com