Method and device for manufacturing water-heating braided hose steel bushing

A production method and a braided tube technology are applied in the field of metal processing and forming, which can solve the problems of complex processing procedures and drawing dies, low utilization rate of steel materials, low production efficiency, etc. Easy-to-install effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

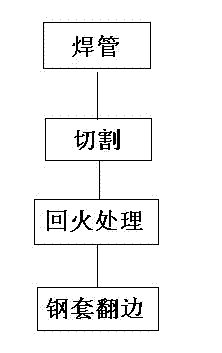

[0025] Such as figure 1 As shown, the invention discloses a method for manufacturing a water heating braided pipe steel sleeve, comprising the following steps:

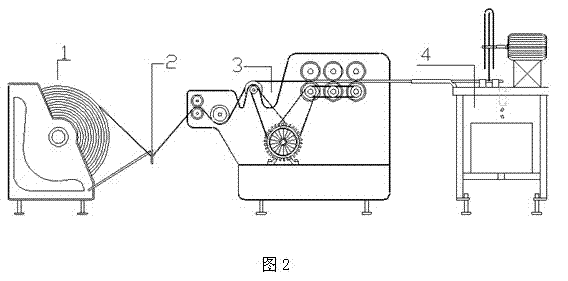

[0026] Step 1, welded pipe: use welding equipment to weld the stainless steel strip into a welded pipe;

[0027] Step 2, cutting: use a cutting machine to cut the welded pipe;

[0028] Step 3, tempering treatment: Tempering the cut welded pipe sections;

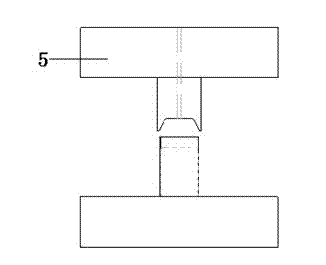

[0029] Step 4, steel sleeve flanging: using a flanging mold to flang the tempered welded pipe sections as required to form a steel sleeve.

[0030] In this embodiment, the size requirements of the stainless steel strip are as follows: the thickness is 0.25-0.30 mm, the width is the circumference of the steel sleeve, and the length is not limited.

[0031] The material requirements of the stainless steel belt are as follows: the stainless...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com