Recycling process of hot and humid air generated in wheat processing

A moist and hot air, processing technology, applied in the direction of transporting passenger cars, tank cars, railway car body parts, etc., can solve problems such as affecting the balance of the wheat milling system and product quality, increasing construction and equipment investment, and reducing the toughness of the wheat cortex. The effect of increasing social benefits and corporate economic benefits, saving warehouse capacity, and shortening the time of wheat moistening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

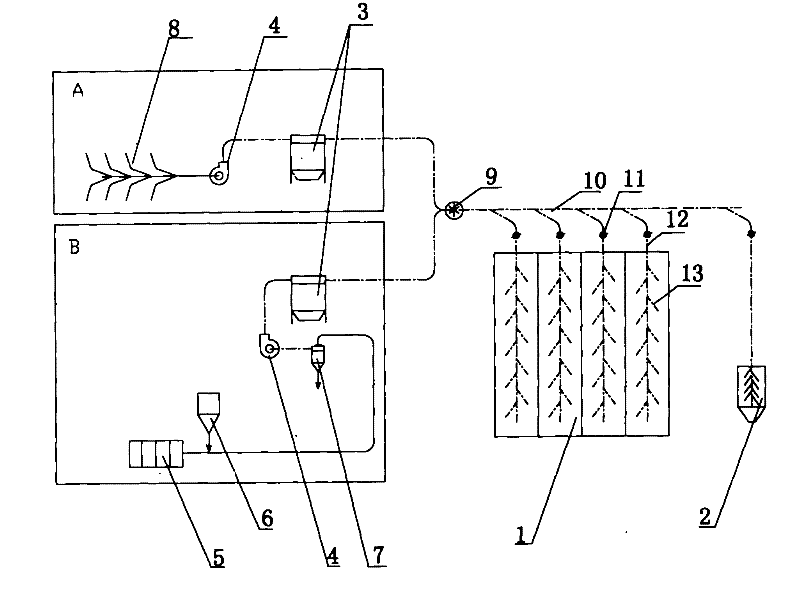

[0040] A hot and humid air recycling process in the wheat processing process, the process steps are as follows (200 tons of wheat processed per day, 4 wheat moistening bins of 3m×3m×18m, 1 clean wheat bin with a diameter of 2m and a height of 3m, 1 group of conveying Wind net as an example):

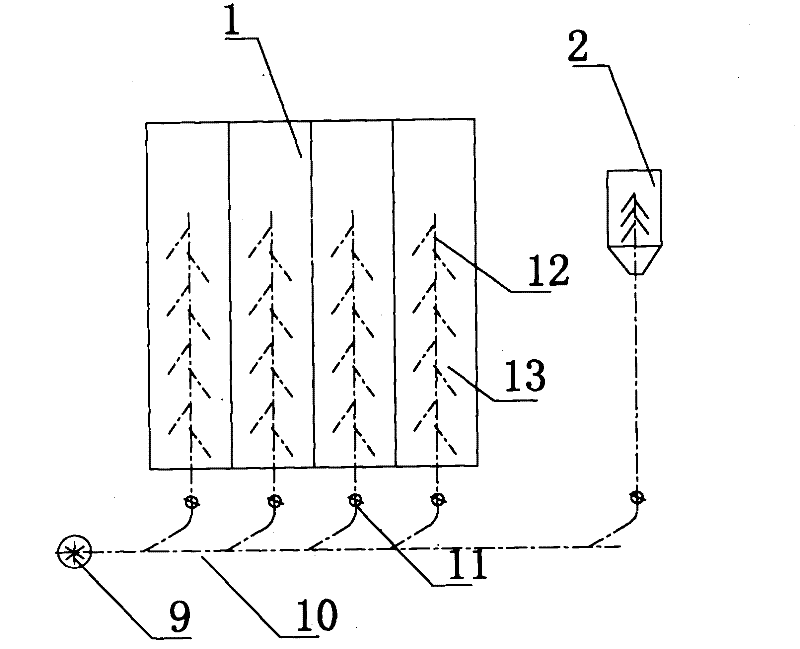

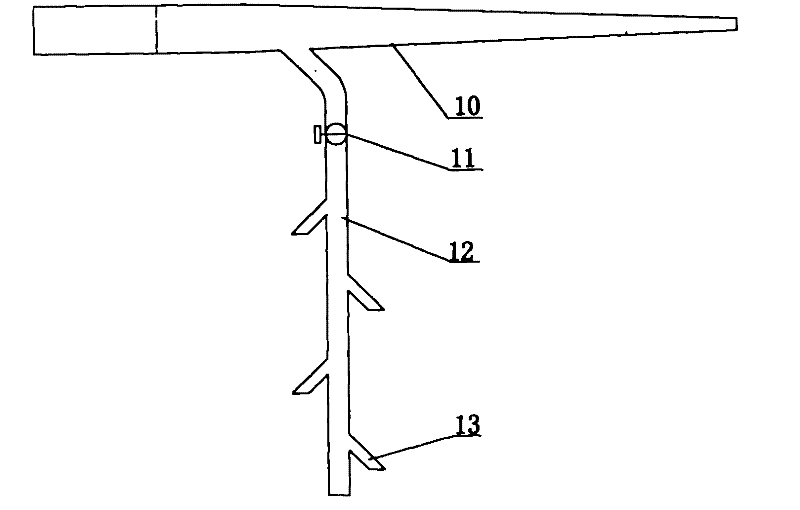

[0041] 1. The humid and hot air that was originally discharged into the atmosphere by the pneumatic conveying wind network is improved into the collection mixer 9 (the mixer adopts a powered impeller pressurized type, and the power is equipped with 5.5kw), and then enters the collection pipe 10 (the diameter of the large head of the collection pipe 600mm, small head diameter 200mm, length 12m), wind speed inside the pipe 16m / s;

[0042] 2. At the corresponding position on the collecting pipe at the central part of the wheat moistening bin 1, the opening is connected to the branch pipe 12 for entering and exiting the bin. The diameter of the branch pipe entering the warehouse is 150mm, t...

Embodiment 2

[0048] A kind of hot and humid air recycling process in wheat processing, the process steps are as follows (300 tons of wheat processed per day, 8 wheat moistening bins of 2m×3m×18m, 1 clean wheat bin with a diameter of 2m and a height of 3m):

[0049] 1. Introduce the hot and humid air from the food workshop into the atmosphere into the collection mixer (the mixer adopts a powered impeller pressurized type, and the power is equipped with 5.5kw), and then enters the collection pipe (the diameter of the large head of the collection pipe is 500mm, and the diameter of the small head 300mm, length 14m), the wind speed inside the pipe is 12m / s;

[0050] 2. At the corresponding position on the collecting pipe corresponding to the central part of the bottom of the wheat conditioning bin, the opening is connected to the branch pipe for entering and exiting the bin. The diameter of the branch pipe entering the warehouse is 200mm, the length is 1.5m, and the wind speed in the pipe is 10...

Embodiment 3

[0056] A hot and humid air recycling process in wheat processing, the process steps are as follows (200 tons of wheat processed per day, four 3m×3m×17m wheat moistening bins, one clean wheat bin with a diameter of 2m and a height of 2.6m, 1 group Conveying wind net, 1 group of bran drying system as an example):

[0057] 1. The hot and humid air originally discharged into the atmosphere by the pneumatic conveying wind net and the bran drying system is changed into the collection mixer (the mixer adopts a powered impeller pressurized type, and the power is equipped with 7.5kw), and then enters the collection pipe (collection The diameter of the big head of the pipe is 650mm, the diameter of the small head is 200mm, and the length is 15m), and the wind speed in the pipe is 18m / s;

[0058] 2. At the corresponding position on the collecting pipe in the center of the wheat moistening bin, the opening is connected to the branch pipe entering and exiting the bin. The diameter of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com