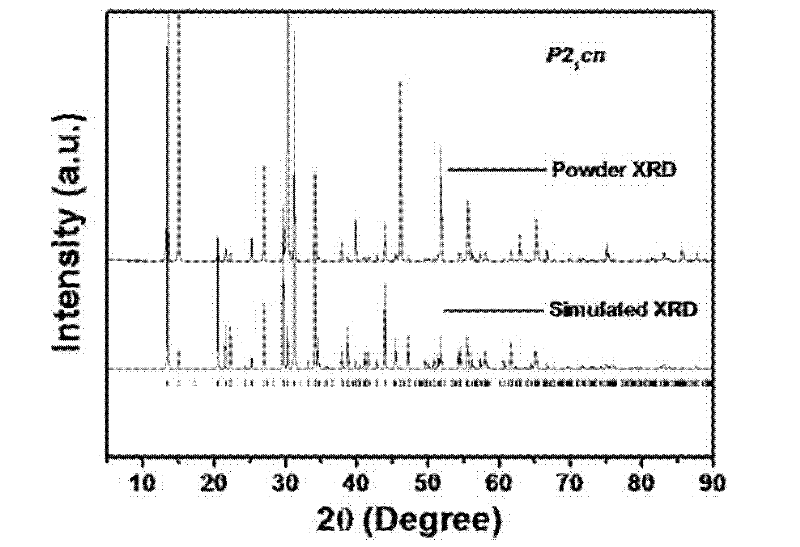

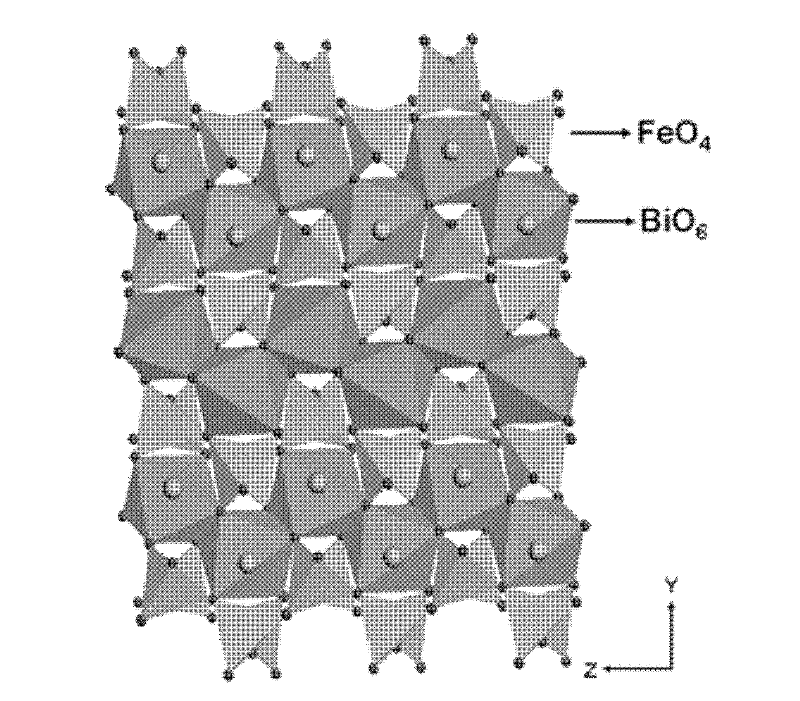

Single-phase multi-ferric material and preparation method thereof

A multi-ferroic material and single-phase technology, applied in chemical instruments and methods, iron compounds, manganate/permanganate, etc., can solve problems such as limited perovskite oxides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

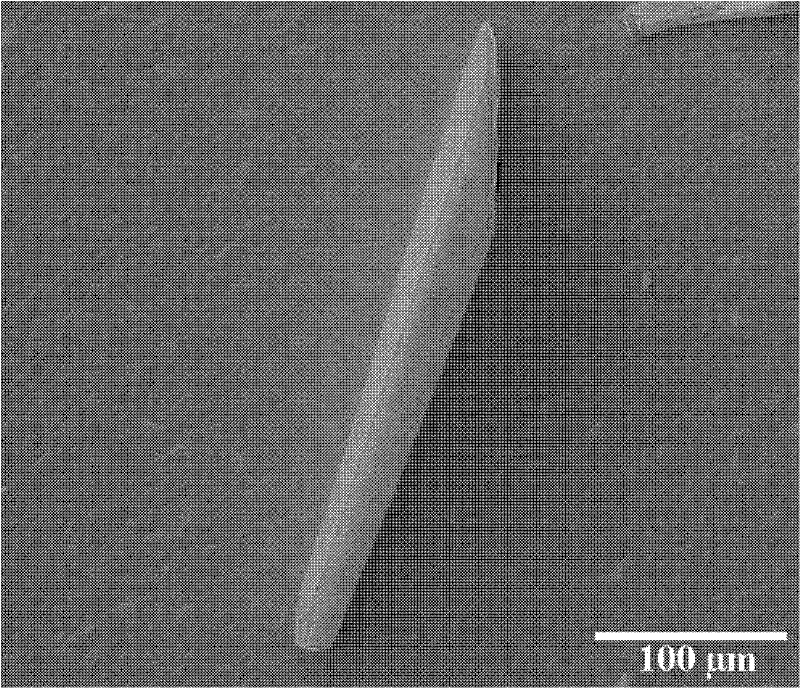

[0028] Preparation of KBiFe in the above single-phase multiferroic materials 2 o 5 The hydrothermal synthesis method, specifically:

[0029] 1) The reaction raw material Bi(NO 3 ) 2 and Fe(NO 3 ) 3 Both were made into a clear solution, and the solution was taken according to the molar ratio of 1:2, and stirred evenly on a magnetic stirrer;

[0030] 2) Add KOH solid directly to the above mixed solution to make the alkalinity of the solution reach more than 5mol / L, and mix the mixture evenly under continuous stirring;

[0031] 3) After the above mixture is cooled to room temperature, transfer it to a reactor with a filling degree of less than 80%, react in a 393-533K oven for 1-7 days, then cool the reactor to room temperature, and release the pressure;

[0032] 4) The synthesized sample was cleaned with deionized water, and ultrasonically treated in an ultrasonic oscillator to obtain a small black crystal sample, and finally the sample was dried in an oven at 60°C.

Embodiment 2

[0034] Preparation of CsBiFe in the above single-phase multiferroic materials 2 o 5 The hydrothermal synthesis method, specifically:

[0035] 1) The reaction raw material Cs 2 CO 3 、 Bi 2 o 3 and Fe(NO 3 ) 3 Add water according to the molar ratio of 1:1:2, and stir evenly on a magnetic stirrer;

[0036] 2) Add KOH solid directly to the above mixed solution to make the alkalinity of the solution reach more than 5mol / L, and mix the mixture evenly under continuous stirring;

[0037] 3) After the above mixture is cooled to room temperature, transfer it to a reactor with a filling degree of less than 80%, react in a 393-533K oven for 1-7 days, then cool the reactor to room temperature, and release the pressure;

[0038] 4) The synthesized sample was washed with deionized water and sonicated in an ultrasonic oscillator to obtain a black sample, and finally the sample was dried in an oven at 60°C.

Embodiment 3

[0040] Preparation of KBiCo in the above single-phase multiferroic materials 2 o 5 The hydrothermal synthesis method, specifically:

[0041] 5) The reaction raw material Bi(NO 3 ) 2 and Co(NO 3 ) 2 Both were made into a clear solution, and the solution was taken according to the molar ratio of 1:2, and stirred evenly on a magnetic stirrer;

[0042] 6) Add KOH solid directly to the above mixed solution to make the alkalinity of the solution reach more than 5mol / L, and mix the mixture evenly under continuous stirring;

[0043] 7) After the above mixture is cooled to room temperature, transfer it to a reactor with a filling degree of less than 80%, react in a 393-533K oven for 1-7 days, then cool the reactor to room temperature, and release the pressure;

[0044] 8) The synthesized sample was washed with deionized water and sonicated in an ultrasonic oscillator to obtain a black sample, and finally the sample was dried in an oven at 60°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com