Multi-stage series ozone catalytic oxidation deep treatment device and preparation method of catalyst applied to same

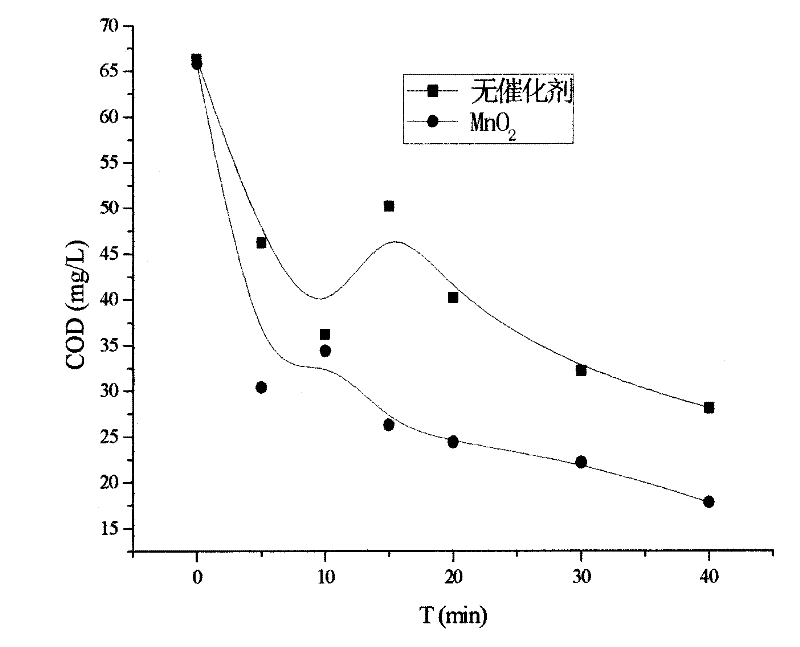

A technology of ozone catalytic oxidation and advanced treatment, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, water/sewage multi-stage treatment, etc. , affect water quality and other issues, to achieve the effect of improving ozone utilization rate, increasing reactivity, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

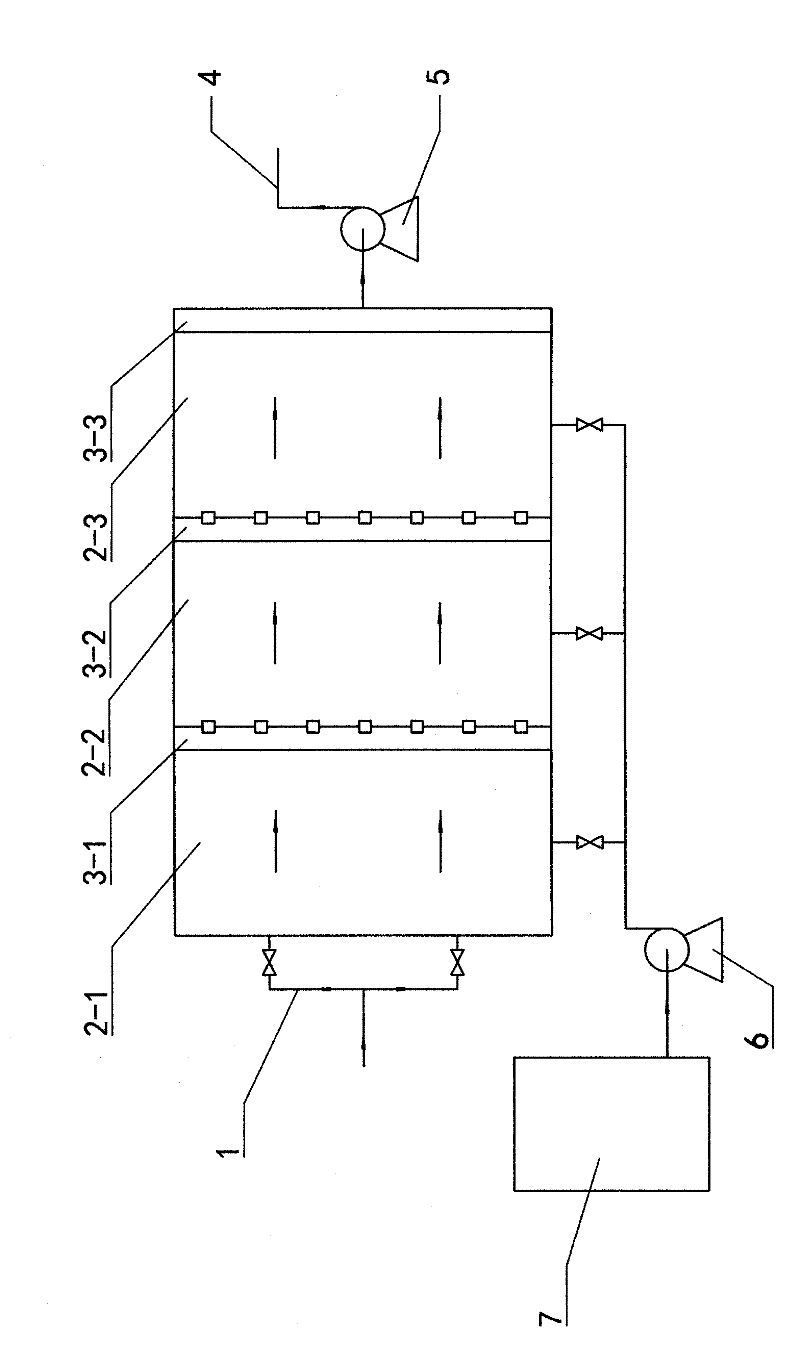

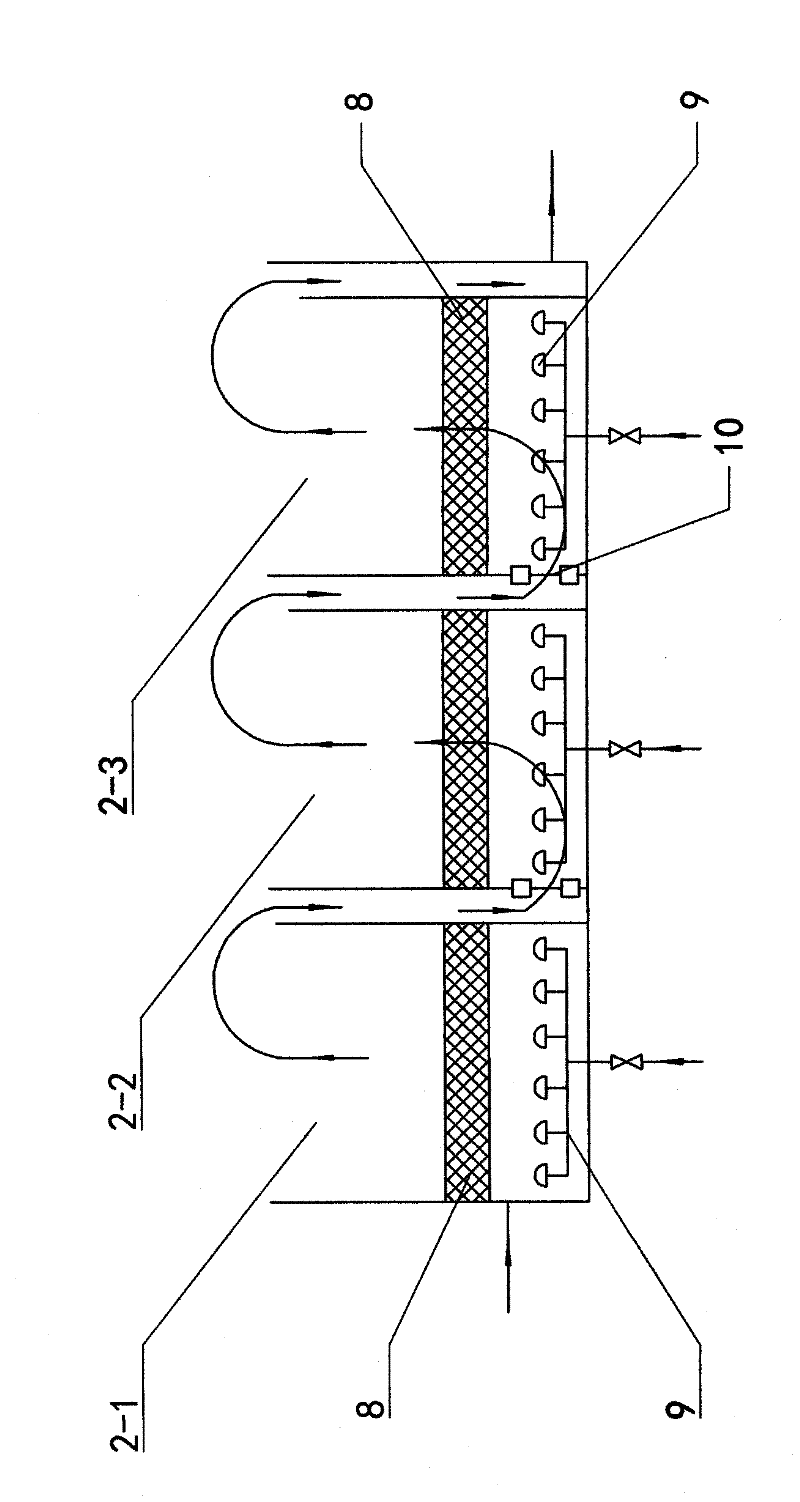

[0042] Example 1: Three-stage series ozone catalytic oxidation advanced treatment device.

[0043] Such as figure 1 , 2 As shown, a three-stage series-connected ozone catalytic oxidation advanced treatment device provides an equipment system for treating and reusing waste water from refineries. The water drain is controlled by the water inlet part 1 through the regulating valve. Enter the bottom of the first reaction tank 2-1, after fully contacting and reacting with the ozone released by the gas distribution device 9 and the catalyst layer 8, it flows upward and overflows to the first water storage tank 3-1, and the first water storage tank 3-1 The bottom of the partition wall is provided with a plurality of water outlets 10, and the sewage enters the second reaction tank 2-2 along the water outlets 10, repeats the above process, passes through the second water storage tank 3-2, the third reaction tank 2-3 successively, and passes through three times and After the catalyst ...

Embodiment 2

[0048] Embodiment 2: method for preparing catalyst with large particle size and high strength

[0049] 1) Weigh 4 kg of diaspore powder, add 1.5 L of 10% manganese nitrate, and mix in a blender for 30-80 minutes;

[0050] 2) preparing a weight concentration of 5% to 20% manganese nitrate solution, called binder solution;

[0051] 3) Spray into the binder solution, the spraying amount is 3% to 50% of the powder weight, and the particle size of the granulation is controlled to be 6 to 15mm;

[0052] 4) Curing the particulate matter prepared in step 3) with water vapor at room temperature for 4 to 8 hours;

[0053] 5) drying the particulate matter obtained in step 4): the drying temperature is 100-150° C., and the drying time is 2-5 hours;

[0054] 6) Calcining the dried particles in step 5) at 350°C to 800°C for 2 to 8 hours to obtain a primary catalyst carrier;

[0055] 7) Immerse the primary catalyst carrier prepared in step 6) into a manganese nitrate solution with a weigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com