Method of converting glycerin for preparation of lactic acid

A technology of glycerol and lactic acid, applied in the field of lactic acid, can solve the problems of environmental pollution, high production cost and high energy consumption, and achieve the effect of reducing production cost and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

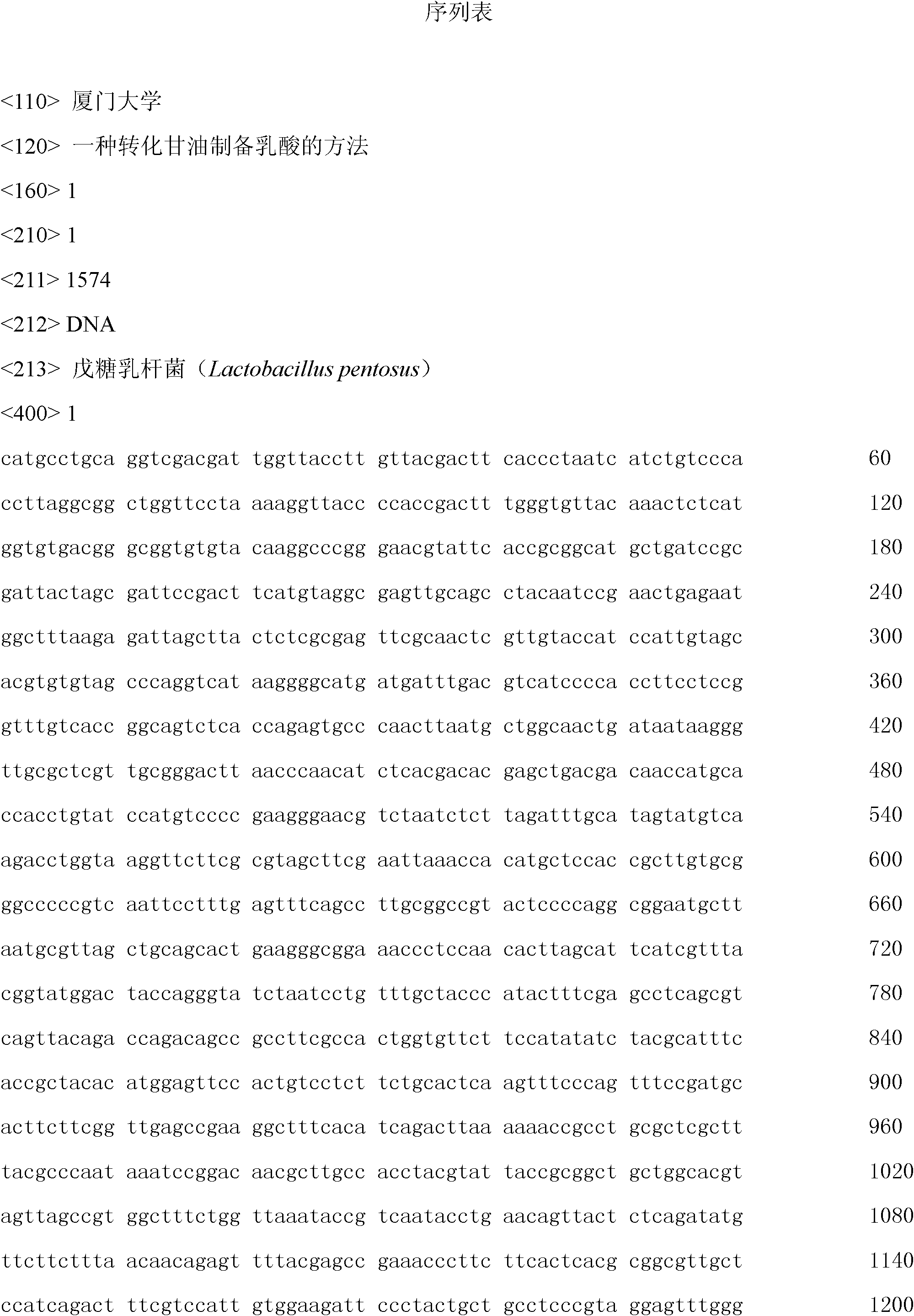

[0025] (1) Isolation and purification of strains

[0026] Put 1g of fresh soil sample or 1ml of water sample into 100mL enrichment medium, enrich and cultivate for 48h, take 5ml of enrichment culture medium and transfer it into new enrichment medium, and transfer for 3 generations in turn. Take 1ml of the enriched culture solution, serially dilute it with a 10-fold gradient, and select an appropriate dilution (10 -4 , 10 -5 , 10 -6 ) bacterial suspension 0.5ml, mixed with the separation medium and poured onto the plate. After culturing for 48 hours at 37°C, pick the strain with a large transparent circle. Transfer the obtained strains into a liquid fermentation medium, and after static cultivation at 37°C for 72 hours, after the fermentation is complete, measure the concentration of lactic acid in the fermentation broth according to the following method:

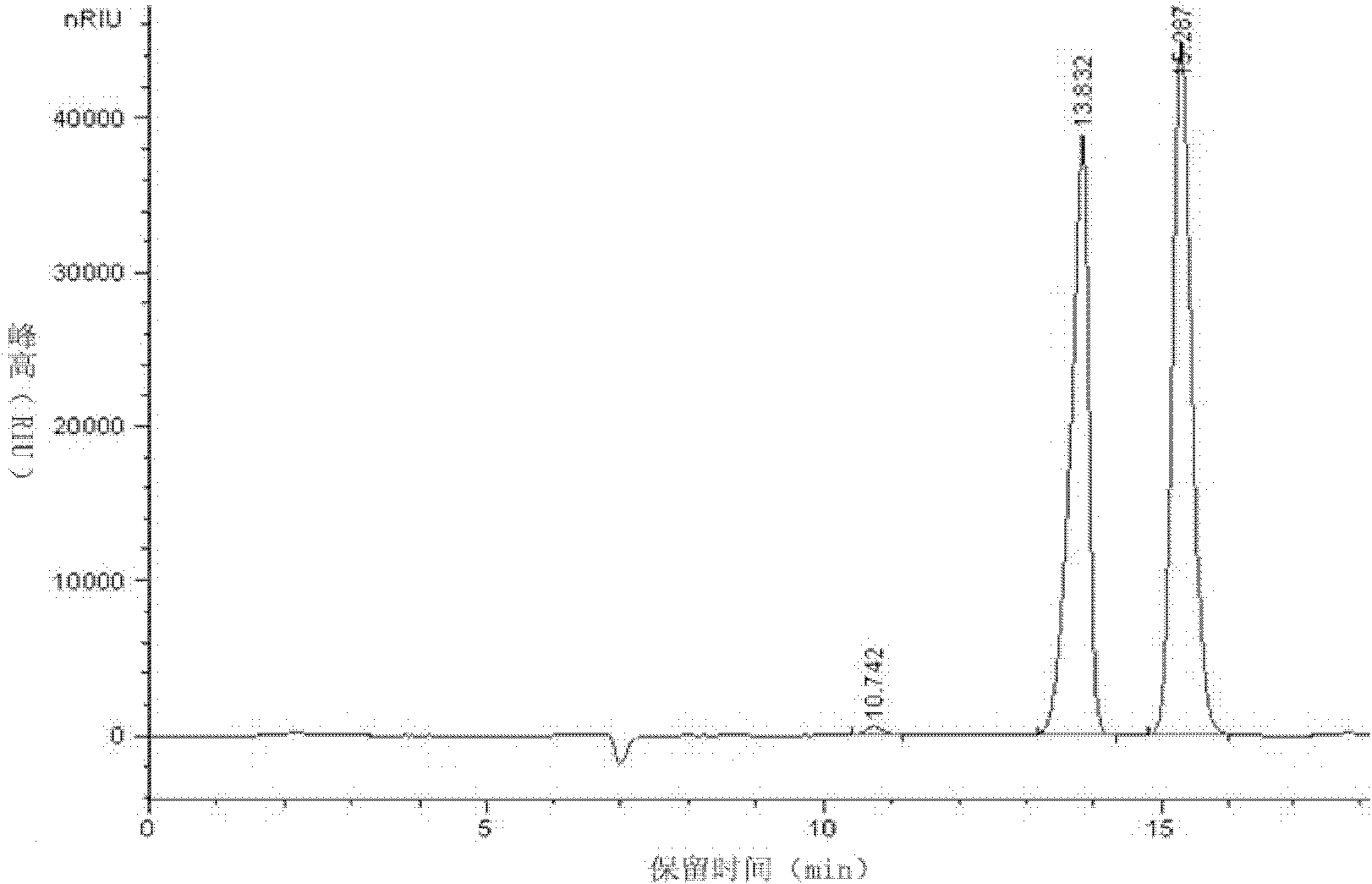

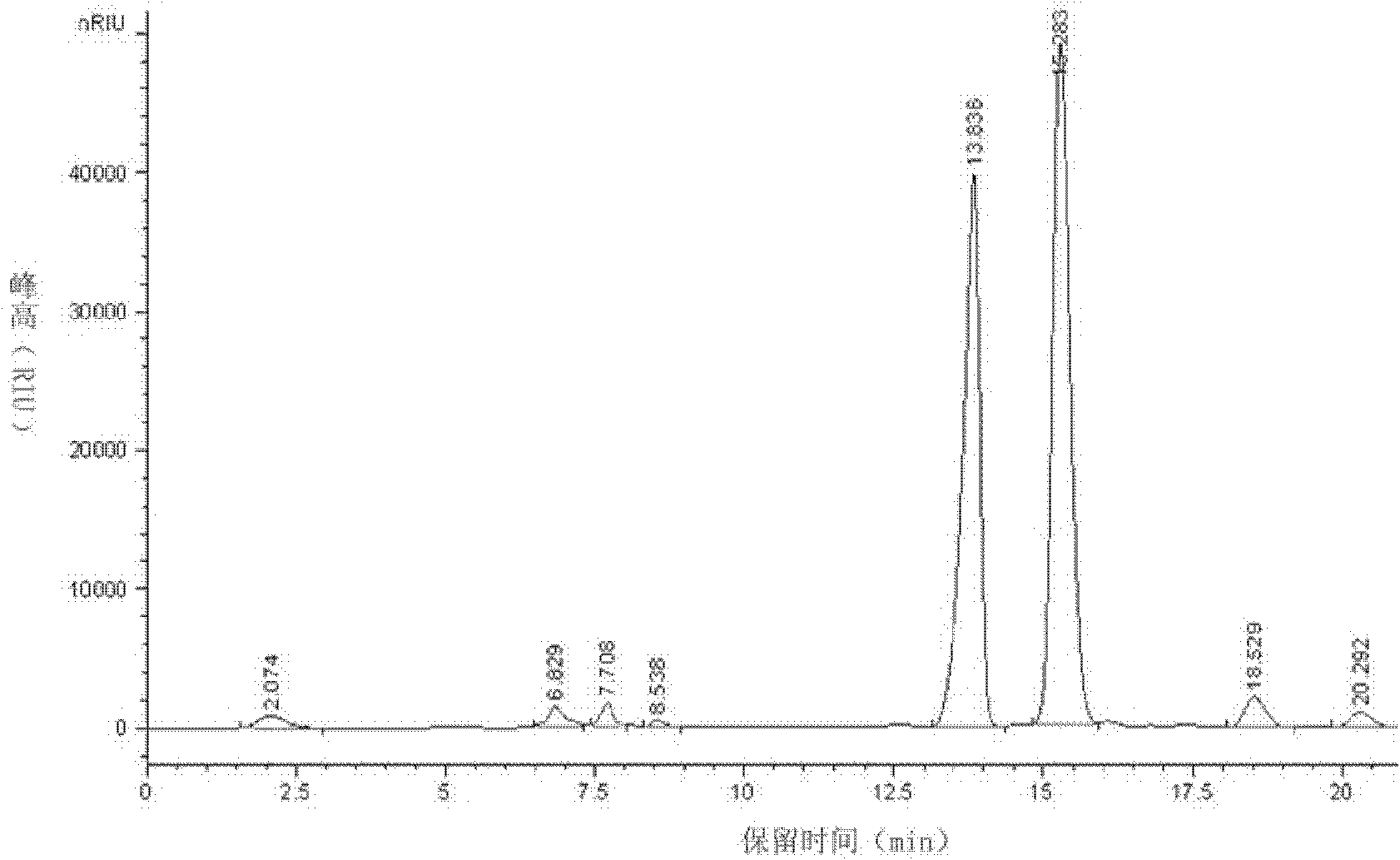

[0027] The reaction product was qualitatively and quantitatively analyzed by high-performance liquid chromatography (A...

Embodiment 2

[0067] (1) Fermentation method: 250ml triangular flask, stand for fermentation.

[0068] (2) Strains: Lactobacillus pentosus R3-8CGMCC No.4726.

[0069] (3) Medium:

[0070] Seed medium (g / L): peptone 10, yeast extract 5, K 2 HPO 4 2. Sodium acetate 5, pure glycerin 20, pH 6.5, 0.1MPa sterilization for 20min.

[0071] Fermentation medium (g / L): peptone 10, yeast extract 6, K 2 HPO 4 1.5, sodium acetate 6, waste glycerol (glycerol content about 96% w / w) 80, CaCO 3 (Separate sterilization) 30, pH 6.5, 0.1MPa sterilization for 20min.

[0072] (4) Fermentation process:

[0073] Seed culture: Inoculate Lactobacillus pentosus into a seed medium containing 20g / l glycerol (250ml Erlenmeyer flask, liquid volume: 100ml), and culture it statically at 37°C for 8h.

[0074] Fermentation culture: transfer the seed solution to the fermentation medium (250ml Erlenmeyer flask, liquid volume 100ml) containing 80g / l waste glycerol according to the inoculum size of 6%, and culture it stat...

Embodiment 3

[0078] (1) Fermentation method: 5L mechanical stirring fermenter, batch fermentation with air.

[0079] (2) bacterial classification: with embodiment 2.

[0080] (3) Medium:

[0081] Seed medium (g / L): peptone 10, yeast extract 5, K 2 HPO 4 2. Sodium acetate 5, pure glycerin 20, pH 6.5, 0.1MPa sterilization for 20min.

[0082] Fermentation medium (g / L): peptone 10, yeast extract 6, K 2 HPO 4 1.5, sodium acetate 6, waste glycerol (glycerin content about 96% w / w) 80, pH 6.5, 0.1MPa sterilization for 20min.

[0083] (4) Fermentation process:

[0084] Seed culture: with embodiment 2.

[0085] Fermentation culture: Use a 5L fermenter with a liquid volume of 2L, control the fermentation temperature at 34°C, and automatically adjust the pH to 6.0 with a NaOH solution with a concentration of 7.5mol / L. l The fermentation medium of waste glycerin, the stirring speed is 250rpm, the air volume is 0.8vvm, and the fermentation time is 96h.

[0086] (5) Fermentation result:

[0087...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com