A kind of strain and method for degrading naringin

A technology of naringin and strains, applied in the field of degrading naringin, can solve the problem of high cost, and achieve the effects of simple nutritional requirements and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

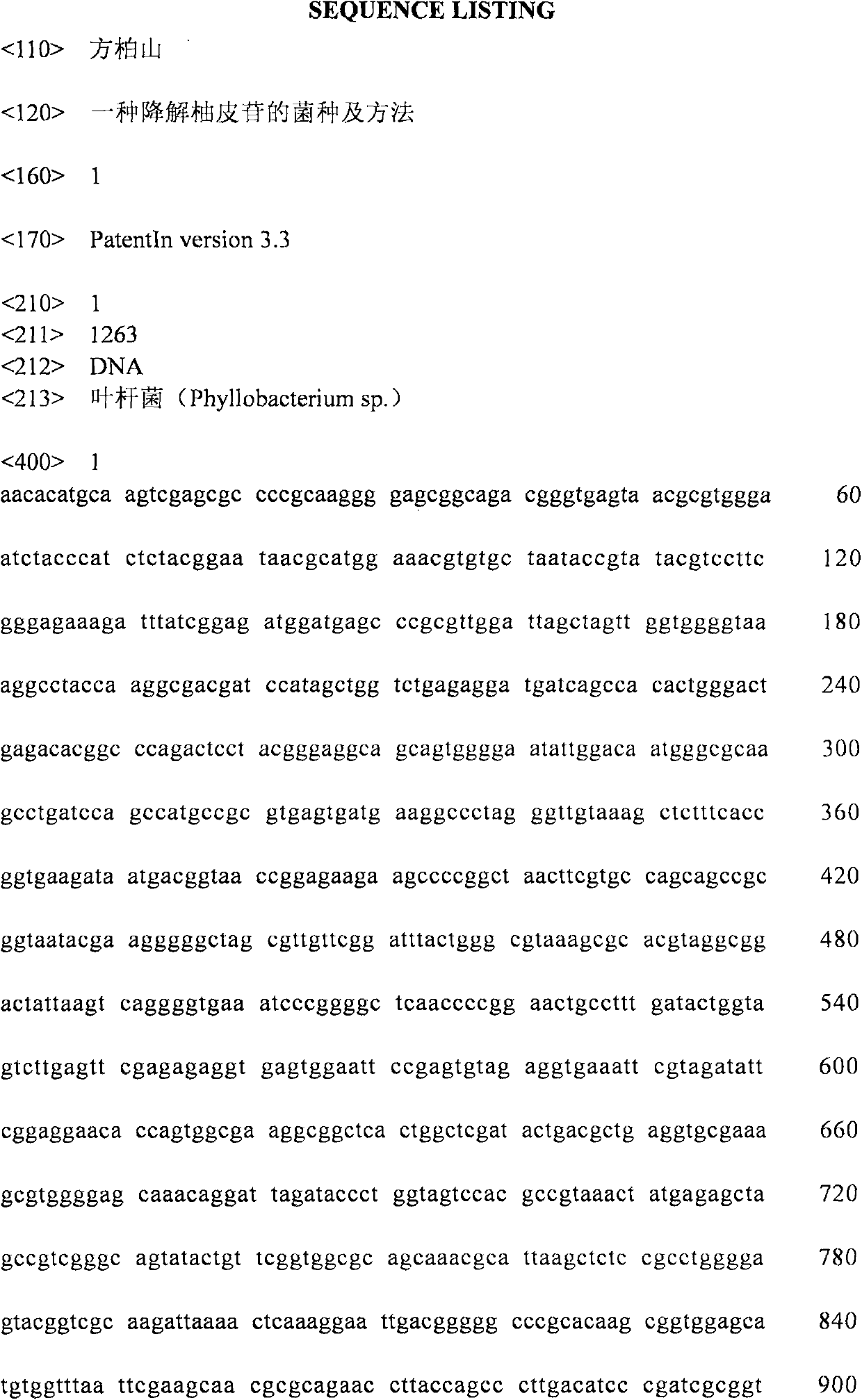

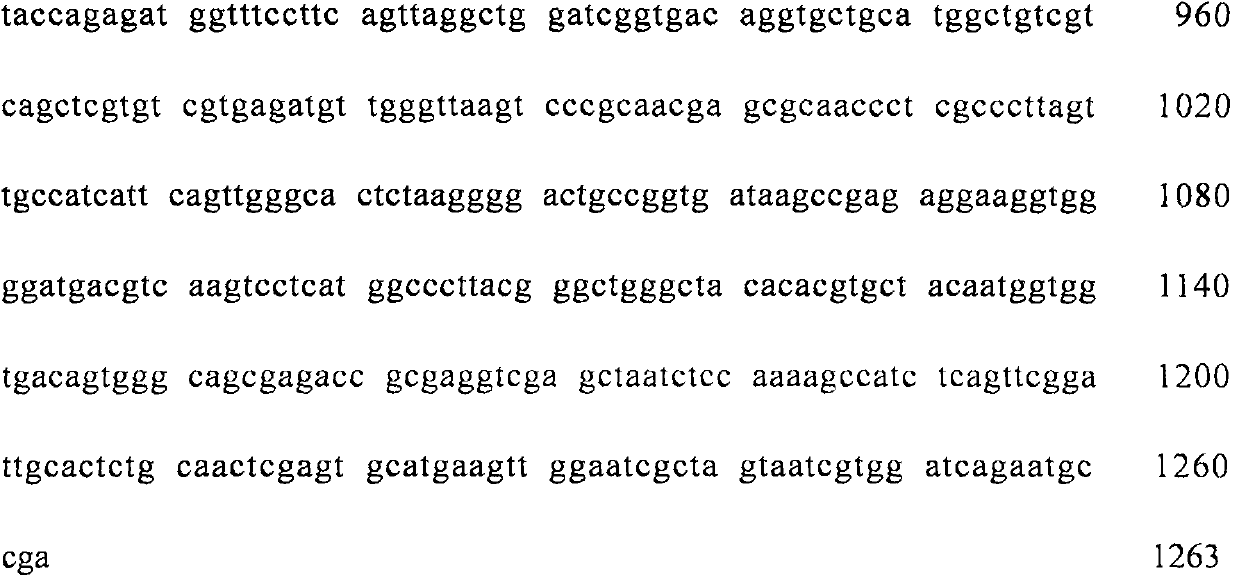

Image

Examples

Embodiment 1

[0034] (1) Isolation and purification of strains

[0035] Take 1g of fresh soil sample from pomelo orchard and add it to 100mL enrichment medium for 48 hours, then take 1mL of enrichment medium and transfer it to a new enrichment medium for continuous enrichment culture for 3 generations. Take 1mL of the enriched culture solution, perform serial dilutions with a 10-fold gradient, and select an appropriate dilution (10 -1 , 10 -5 , 10 -6 ) bacterial suspension 0.2mL, spread in the isolation medium, place in a 30°C incubator and cultivate for 72 hours, pick all the growing strains and separate them by streaking. Continuously streaked and cultured for 3 generations to obtain purified strains. Transfer these pure bacterial strains to liquid medium, 30 ℃, 150rpm, shaker culture, after cultivating 72h, measure the change situation of naringin content according to the following method:

[0036] Determination by high performance liquid chromatography, the conditions are: mobile ph...

Embodiment 2

[0046] Determination of growth curve and degradation of naringin.

[0047] Strain: Phyllobacterium sp. Wb51b CGMCC No. 6472.

[0048] Medium:

[0049] Seed medium (g / L): glucose 1; yeast powder 2; peptone 0.5; naringin 0.5; pH 3.0-5.0, 0.1MPa, sterilized for 20 minutes.

[0050] Fermentation medium (g / L): naringin 2; ammonium sulfate 1; dipotassium hydrogen phosphate 1; anhydrous calcium chloride 0.2; magnesium sulfate 0.5; pH 3.0-6.0, 0.1MPa, sterilization for 20 minutes.

[0051] Seed culture: Inoculate Phyllobacterium sp.Wb51b CGMCC No.6472 into a medium containing 0.5g / L naringin (250mL Erlenmeyer flask, liquid volume 100mL), temperature 30°C, rotation speed 150rpm, shaker culture for 24h.

[0052] Fermentation culture: Inoculate the Phyllobacterium sp.Wb51b CGMCC No.6472 strain after seed culture culture into the fermentation medium, the culture conditions are the same as the seed culture, and samples are taken every 4h to measure the biomass OD respectively 600nm and ...

Embodiment 3

[0057] Degradation of naringin by free cells

[0058] Strain: Phyllobacterium sp. Wb51b CGMCC No. 6472.

[0059] Medium (g / L): naringin 2; yeast extract 0.1; ammonium sulfate 1: calcium chloride 0.2; magnesium sulfate 0.5; dipotassium hydrogen phosphate 1;

[0060] Phyllobacterium sp.Wb51b CGMCC No.6472 was inoculated into the seed medium at a temperature of 30° C. and a rotational speed of 150 rpm, and cultured on a shaker for 72 hours.

[0061] Isolation of free cells:

[0062] The Phyllobacterium sp.Wb51b CGMCC No.6472 cells cultured for 72 hours were collected and centrifuged for 10 minutes in a centrifuge with a temperature of 4° C., a rotation speed of 8000 rpm, and a capacity of 50 mL. Discard the supernatant, wash three times with PBS buffer with pH 6.0 to remove naringin contained in the cells, and finally suspend the cells with PBS buffer with pH 6.0, and store them in a refrigerator at 4°C for later use.

[0063] Under the conditions of naringin concentration of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com