Method for producing lactic acid by using immobilized cells for converting glycerin

A technology for immobilizing cells and glycerol, applied in the field of lactic acid, can solve the problems of restricting the industrial application of lactic acid production, serious substrate inhibition, low production intensity, etc., and achieve the effects of saving purification and separation costs, low cost, and improving production intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

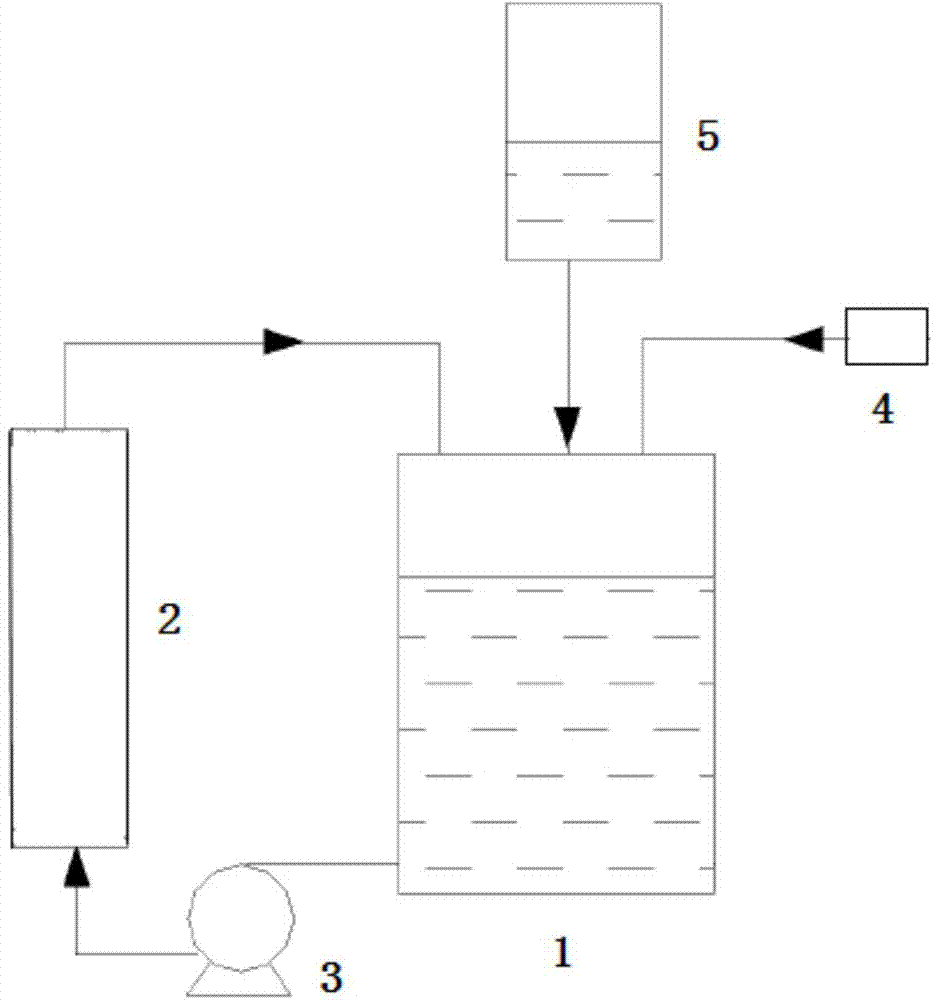

[0032] What this embodiment provides is to carry out the process of batch fermentation of lactic acid by immobilized Lactobacillus pentosus in a fiber bed bioreactor with biodiesel by-product crude glycerol as raw material:

[0033] 1. Culture medium (the glycerol added in the medium is crude glycerol, a by-product of biodiesel, and the concentration of glycerol in the medium refers to the concentration of glycerol contained in the added crude glycerol):

[0034] 1) Seed medium ( / L):

[0035] Glycerin 40g, yeast powder 5g, tryptone 10g, sodium acetate 6g, K 2 HPO 4 1.5g, pH6.5;

[0036]2) Expanded culture medium ( / L): glycerol 40g, yeast powder 6g, tryptone 10g, sodium acetate 6g, K 2 HPO 4 1.5g, MnCl 2 ·H 2 O0.15g, defoamer 0.05g, pH6.0~6.2;

[0037] 3) Fermentation medium ( / L):

[0038] Glycerin 60g, yeast powder 6g, tryptone 10g, sodium acetate 6g, K 2 HPO 4 1.5g, MnCl 2 ·H 2 O0.15g, defoamer 0.05g, pH6.0~6.2;

[0039] 2. Strains: Lactobacillus pentosus R3-8; ...

Embodiment 2

[0050] What this embodiment provides is to carry out the process of feeding batch fermentation of lactic acid by immobilizing Lactobacillus pentosus in a fiber bed bioreactor with biodiesel by-product crude glycerol as raw material:

[0051] 1. Culture medium (the glycerol added in the medium is crude glycerol, a by-product of biodiesel, and the concentration of glycerol in the medium refers to the concentration of glycerol contained in the added crude glycerol):

[0052] 1) Seed medium ( / L):

[0053] Glycerin 40g, yeast powder 5g, tryptone 10g, sodium acetate 6g, K 2 HPO 4 1.5g, pH6.5;

[0054] 2) Expand culture medium ( / L):

[0055] Glycerin 40g, yeast powder 6g, tryptone 10g, sodium acetate 6g, K 2 HPO 4 1.5g, MnCl 2 ·H 2 O0.15g, defoamer 0.05g, pH6.0~6.2;

[0056] 3) Initial fermentation medium ( / L):

[0057] Glycerin 60g, yeast powder 6g, tryptone 10g, sodium acetate 6g, K 2 HPO 4 1.5g, MnCl 2 ·H 2 O0.15g, defoamer 0.05g, pH6.0~6.2;

[0058] 2. Strains: Lact...

Embodiment 3

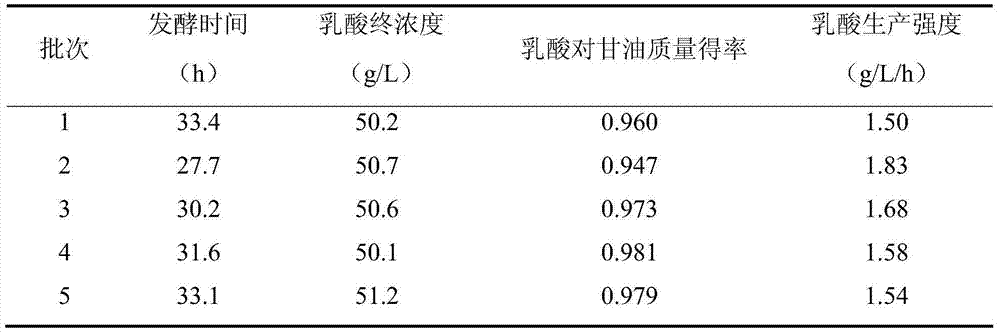

[0068] What this embodiment provides is to carry out the process of repeatedly batch-fermenting lactic acid by immobilized Lactobacillus pentosus in a fiber bed bioreactor with biodiesel by-product crude glycerol as raw material:

[0069] 1. Culture medium (the glycerol added in the medium is crude glycerol, a by-product of biodiesel, and the concentration of glycerol in the medium refers to the concentration of glycerol contained in the added crude glycerol):

[0070] 1) Seed medium ( / L):

[0071] Glycerin 40g, yeast powder 5g, tryptone 10g, sodium acetate 6g, K 2 HPO 4 1.5g, pH6.5;

[0072] 2) Expand culture medium ( / L):

[0073] Glycerin 40g, yeast powder 6g, tryptone 10g, sodium acetate 6g, K 2 HPO 4 1.5g, MnCl 2 ·H 2 O0.15g, defoamer 0.05g, pH6.0~6.2;

[0074] 3) Fermentation medium ( / L):

[0075] Glycerin 60g, yeast powder 6g, tryptone 10g, sodium acetate 6g, K 2 HPO 4 1.5g, MnCl 2 ·H 2 O0.15g, defoamer 0.05g, pH6.0~6.2;

[0076] 2. Strains: Lactobacillus p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com