Preparation method of dihydroxyacetone by transforming glycerol

A technology of dihydroxyacetone and glycerol, which is applied in the field of converting glycerol to prepare dihydroxyacetone, which can solve the problems of long fermentation time, high culture conditions, and low production intensity, and achieve the effects of short fermentation time, high production intensity, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Isolation and purification of strains

[0024] Put 1g of fresh soil sample or 1ml of water sample into 100mL enrichment medium, enrich culture for 3-7 days, take 5ml of enrichment culture medium and transfer it to new enrichment medium, and transfer for 3 generations in turn. Take 1ml of the enriched culture solution, serially dilute it with a 10-fold gradient, and select an appropriate dilution (10 -4 , 10 -5 , 10 -6 ) bacterial suspension 0.5ml, mixed with the separation medium and poured onto the plate. After culturing for 48 hours at 30°C, a single colony was picked. Transfer the obtained bacterial colony into the liquid fermentation medium, shake and cultivate at 30°C for 30 hours, and then measure the concentration of dihydroxyacetone in the fermentation broth according to the following method:

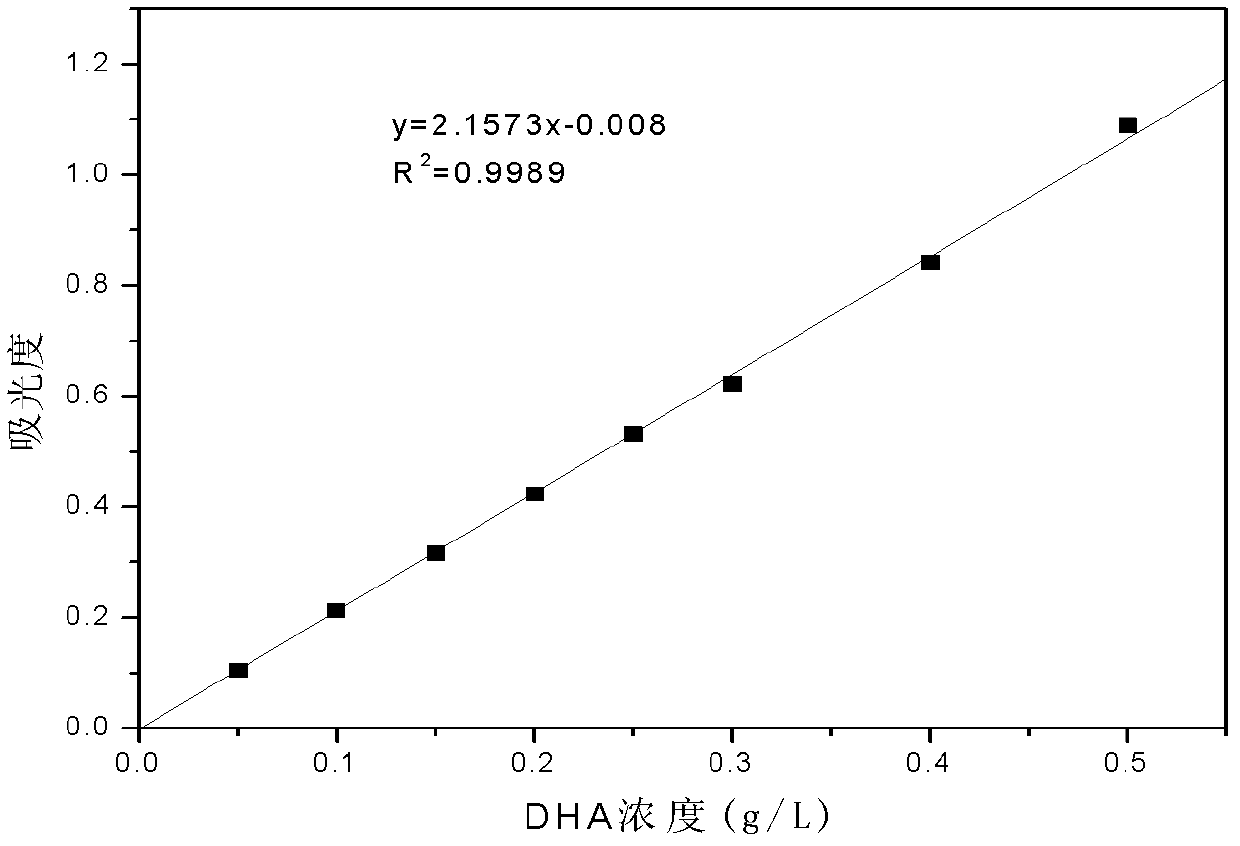

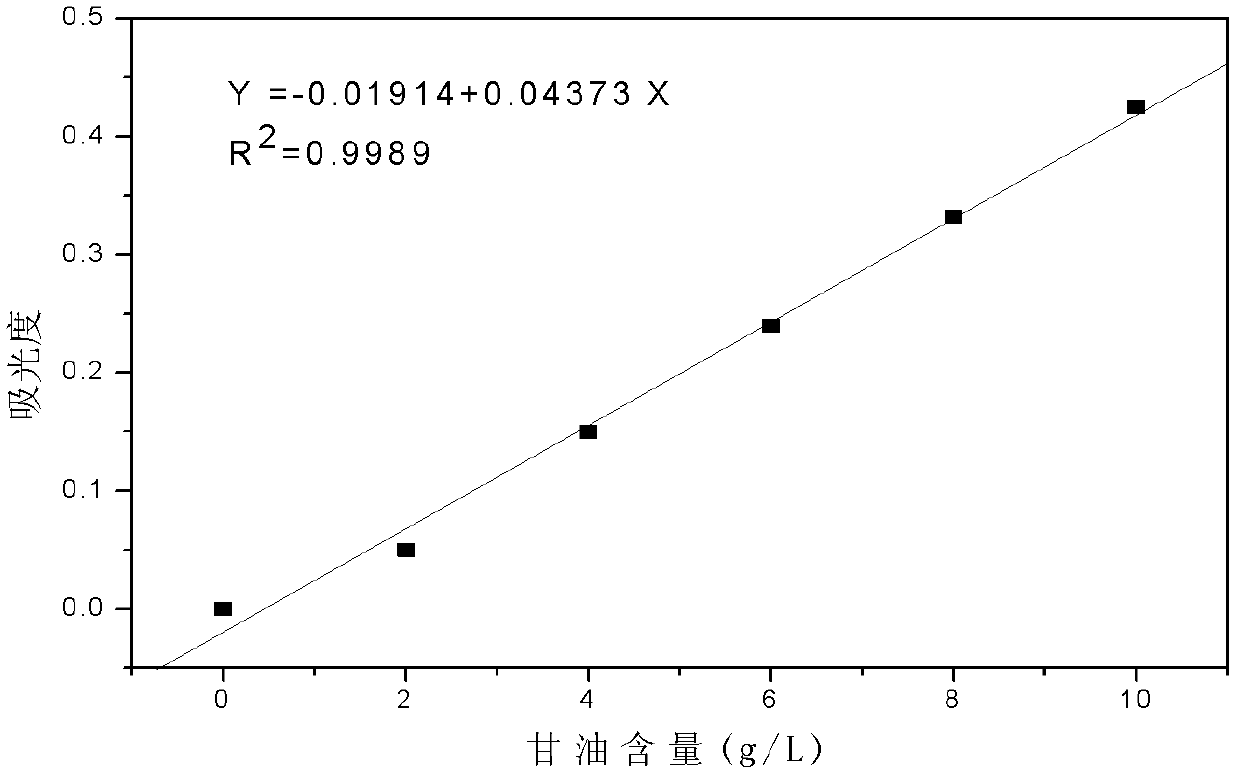

[0025] Determination of dihydroxyacetone (DHA) by diphenylamine chromogenic method: put 0.500 g of the standard sample into a 100 mL volumetric flask, add water t...

Embodiment 2

[0040] (1) Fermentation method: 250ml Erlenmeyer flask, shaker fermentation.

[0041] (2) Strains: Flavobacterium halmsphilum ch20-1.

[0042] (3) Medium:

[0043] Seed medium (g / L): Chen Haihai 1000 (ml), peptone 5, yeast extract 5, K 2 HPO 4 2. Sorbitol 5, pH6.0, 0.1MPa sterilization for 20min.

[0044] Fermentation medium (g / L): aged sea water 1000 (ml), peptone 5, yeast extract 5, K 2 HPO 4 2. Waste glycerin 90, MgSO 4 ·7H 2 O 0.2, MnSO 4 ·H 2 O 0.3, pH 6.0, 0.1MPa sterilization for 20min.

[0045] (4) Fermentation process:

[0046] Seed culture: Inoculate Flavobacterium halophilus into the seed culture medium (250ml Erlenmeyer flask, liquid volume 50ml), and cultivate at 30°C for 16h.

[0047] Fermentation culture: transfer the seed solution to the fermentation medium (250ml Erlenmeyer flask, liquid volume 50ml) containing 90g / l waste glycerol according to the inoculum amount of 5%, and cultivate at 30°C for 30h.

[0048] (5) Fermentation result:

[0049] At ...

Embodiment 3

[0051] (1) Fermentation method: 5L mechanical stirring fermentation tank, batch fermentation with air

[0052] (2) bacterial classification: with embodiment 2

[0053] (3) Medium:

[0054] Seed medium (g / L): Chen Haihai 1000 (ml), peptone 5, yeast extract 5, K 2 HPO 4 2. Sorbitol 5, pH6.0, 0.1MPa sterilization for 20min.

[0055] Fermentation medium (g / L): aged sea water 1000 (ml), peptone 5, yeast extract 5, K 2 HPO 4 2. Waste glycerin 90, MgSO 4 ·7H 2 O 0.2, MnSO 4 ·H 2 O 0.3, pH 6.0, 0.1Mpa sterilization for 20min.

[0056] (4) Fermentation process:

[0057] Seed culture: with embodiment 2

[0058] Fermentation culture: Use a 5L fermenter with a liquid volume of 2L. The fermentation temperature is controlled at 30°C. The pH is automatically adjusted at 6.0 with a concentration of 3mol / L NaOH solution, and the seed solution is transferred to a 90g / l For the fermentation medium of waste glycerol, the stirring speed is 200rpm, the amount of air introduced is 6vvm, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com