New technology for preparing hard wear resistant coating through shaped charge detonation gun spraying

A technology of shaped charge and explosive spraying, which is applied in metal material coating process, coating, melting spraying and other directions, can solve the problems of uneven spray coating, small spraying area, and easy to form pits on the workpiece to be sprayed. Achieve the effect of preventing oxidative decarburization, large coating area and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

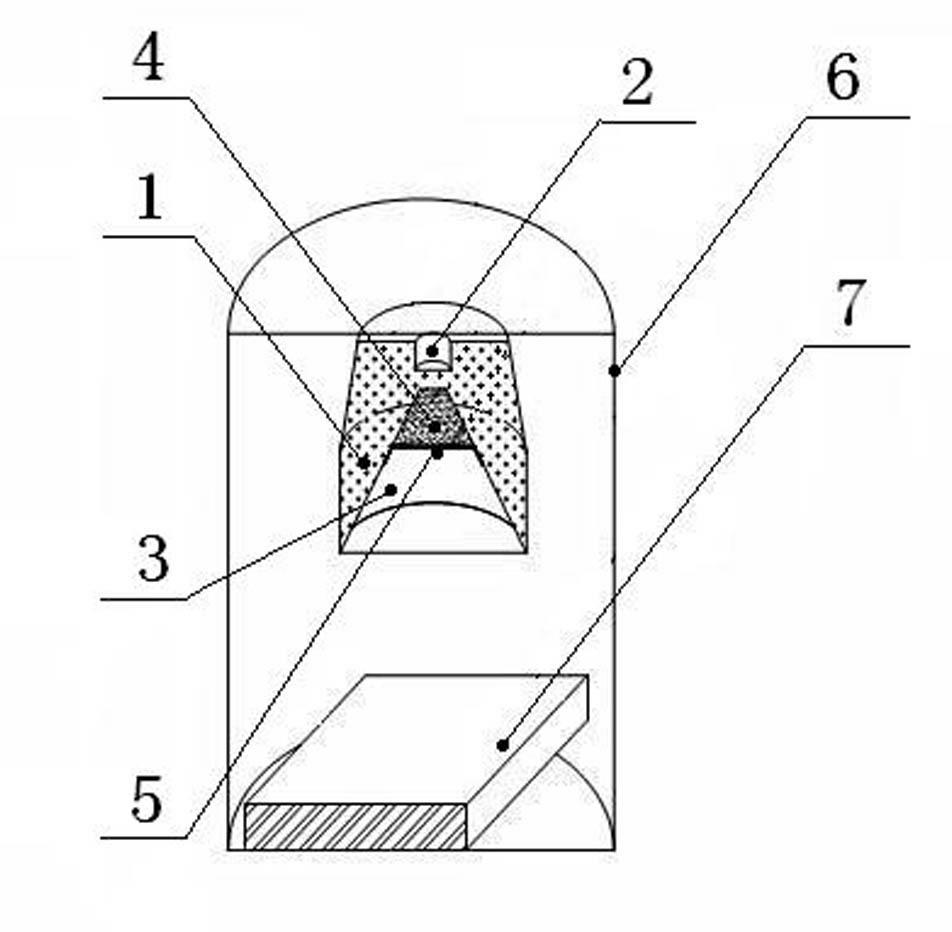

[0025] The workpiece 7 to be sprayed is made of A3 steel with a size of 50 50 5mm 3 . Before spraying, the workpiece 7 to be sprayed is cleaned and pre-treated by sandblasting. The processed workpiece 7 to be sprayed is subjected to explosive spraying with concentrated charge, and the specific spraying process is completed by the following steps:

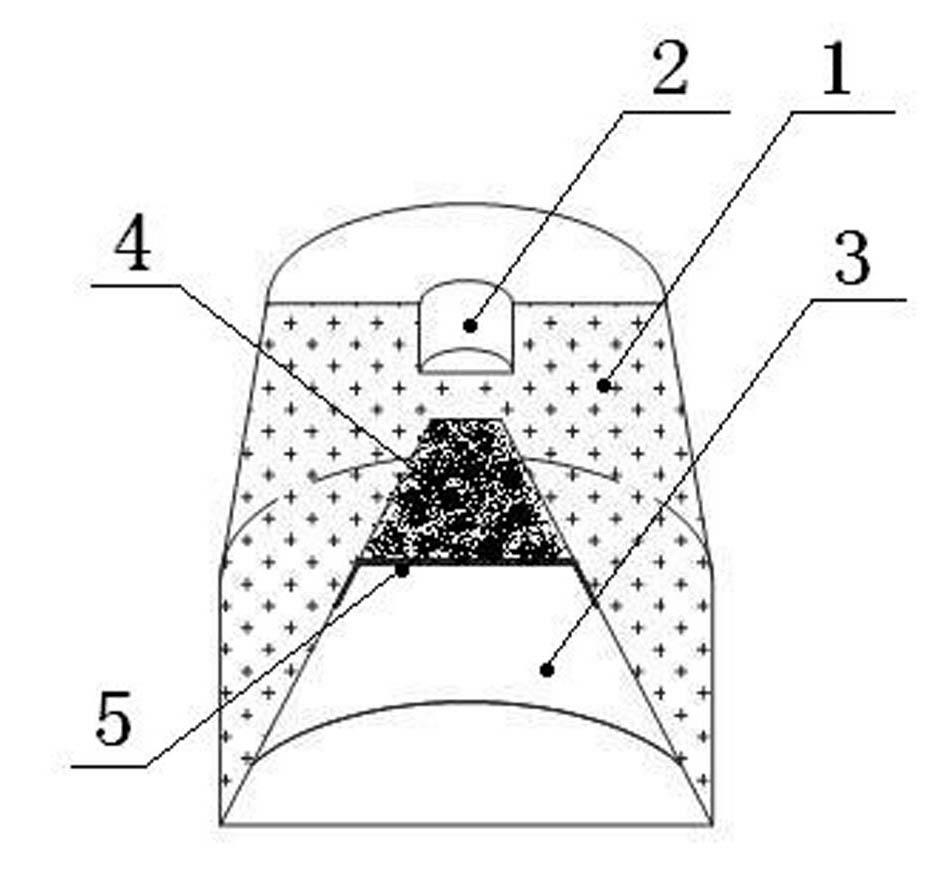

[0026] (1) Compression of shaped charge: put insensitive RDX 1 high-energy explosive 1 into a conical shaped charge mold, and press to a density of 1.3g / cm 3 , the conical shaped charge with a cone angle of 50° in the point 3 of the shaped charge, and an electric detonator is inserted in the detonator slot 2 of the shaped charge;

[0027] (2) Filling of the spraying powder 4: take the spraying powder 4 with a mass of 10% of the mass of the shaped charge and put it into the shaped hole 3 of the inverted shaped charge, so that the powder filling density is 2.5g / cm 3 , and then use the film 5 bonded to the inner wall of the ener...

Embodiment 2

[0032] The workpiece 7 to be sprayed is made of A3 steel with a size of 100 50 5mm 3 . Before spraying, the workpiece 7 to be sprayed is cleaned and pre-treated by sandblasting. The processed workpiece 7 to be sprayed is subjected to explosive spraying with concentrated charge, and the specific spraying process is completed by the following steps:

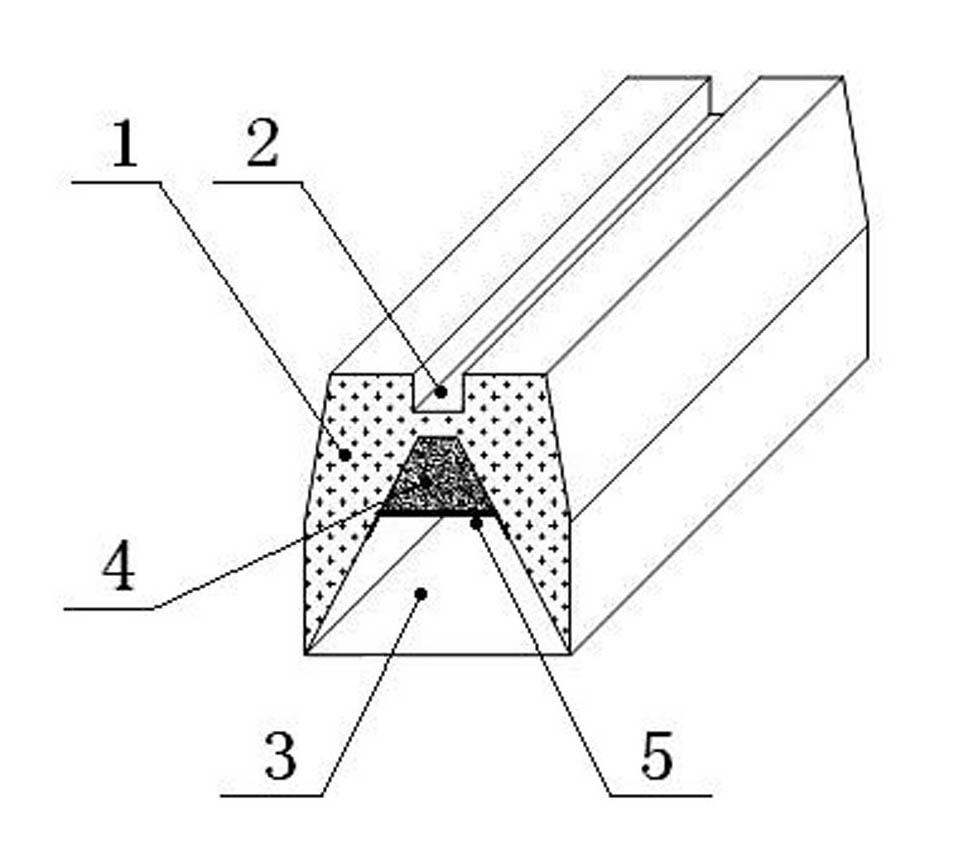

[0033] (1) Compression of shaped charge: put the insensitive Octojin high-energy explosive 1 into a linear shaped charge mold, and press it to a density of 1.5g / cm 31. A linear shaped charge with a taper angle of 60° in the point 3 of the shaped charge, and an electric detonator is inserted in the detonator slot 2 of the shaped charge;

[0034] (2) Filling of the spraying powder 4: take the spraying powder 4 whose mass is 30% of the mass of the shaped charge and put it into the gathering hole 3 of the inverted shaped charge, so that the powder filling density is 2.0g / cm 3 , and then use the film 5 bonded to the inner wall of...

Embodiment 3

[0039] The workpiece 7 to be sprayed is made of A3 steel with a size of 50 50 5mm 3 . Before spraying, the workpiece 7 to be sprayed is cleaned and pre-treated by sandblasting. The processed workpiece 7 to be sprayed is subjected to explosive spraying with concentrated charge, and the specific spraying process is completed by the following steps:

[0040] (1) Compression of shaped charge: put insensitive RDX 1 high-energy explosive 1 into a conical shaped charge mold, and press to a density of 1.6g / cm 3 1. The conical shaped charge with a cone angle of 40° in the point 3 of the shaped charge, and an electric detonator is inserted in the detonator slot 2 of the shaped charge;

[0041] (2) Filling of the spraying powder 4: take the spraying powder 4 whose mass is 20% of the mass of the shaped charge and put it into the gathering hole 3 of the inverted shaped charge, so that the powder filling density is 3.0g / cm 3 , and then use the film 5 bonded to the inner wall of the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com