Silencing unit and internal-combustion engine exhaust silencer using same

A technology of muffler unit and muffler, which is applied in the direction of machines/engines, muffler devices, mechanical equipment, etc., can solve the problems of poor structure of exhaust muffler, deterioration of aerodynamic performance, loss of power consumption of internal combustion engine, etc., and achieve compact structure, reduced The effect of small air resistance and reducing dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

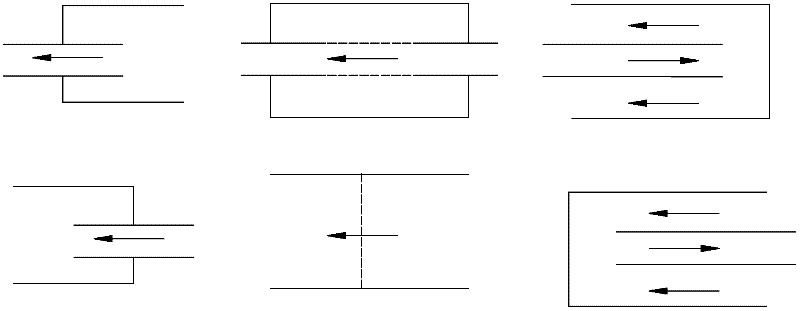

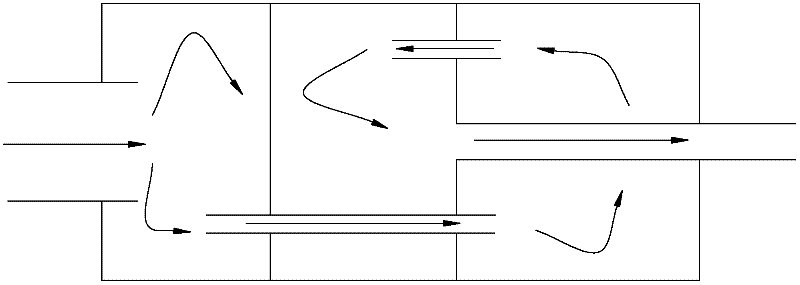

Method used

Image

Examples

Embodiment 1

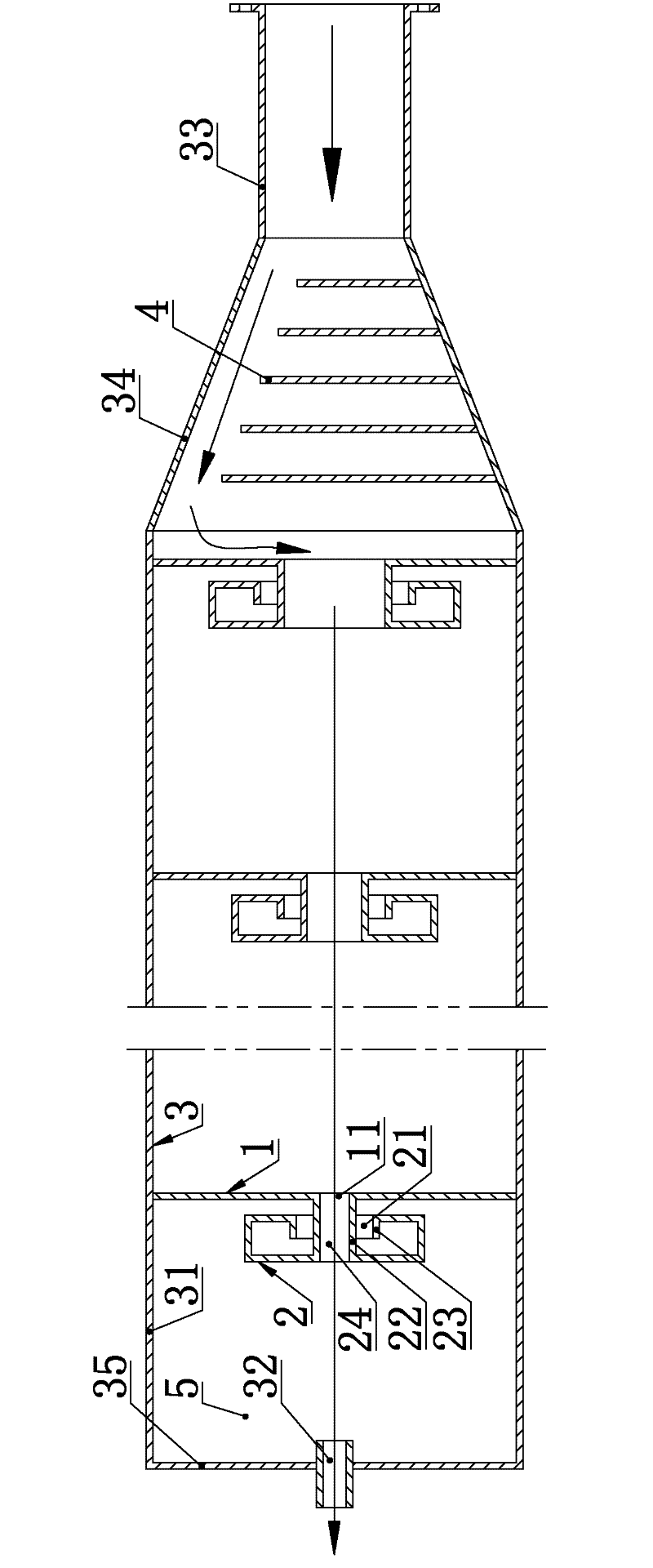

[0041] Such as image 3 , Figure 4 As shown, a kind of internal combustion engine exhaust muffler used for motorcycles includes a cylindrical cavity 5 surrounded by a muffler 3 housing 31, a muffler 3 inlet, and a muffler 3 outlet 32. There are five levels of muffler units inside, and the muffler units include partitions 1 and spiral structures 2 .

[0042] The partition 1 is a circular flat plate that is consistent with the radial section of the cavity 3 and vertical to the axial direction of the cavity 5. The surrounding of the partition 1 is fixedly connected with the housing 31 and axially partitions the cavity 5. coaxial through-hole. The through holes of the partitions 1 of each muffler unit are coaxial with the outlet 32 of the muffler 3, and the air flow path is straight.

[0043] The plane square spiral coiled from the outside to the inside is used as the cross-section contour line. The cross-section contour line includes five sides and the angles between adjace...

Embodiment 2

[0048] Such as Figure 5 , Figure 6 As shown, an internal combustion engine exhaust muffler for motorcycles includes a cylindrical cavity 5 surrounded by a muffler 3 housing 31, a muffler 3 inlet, and a muffler 3 outlet 32, and the muffler 3 is axially installed in the cavity 5. There are five levels of noise reduction units, and the noise reduction units include partitions 1 and spiral structures 2 .

[0049] The partition 1 is an incomplete circular flat plate whose edge is composed of an arc and the chord between the two ends of the arc. The partition 1 is arranged perpendicular to the axial direction of the cavity 5 and axially partitions the cavity 5. The corresponding edge of the arc is fixedly connected with the shell 31, and the air channel 11 is formed by the radial gap between the corresponding edge of the chord and the shell 31. The radial gap corresponding to the adjacent partition 1 is radially symmetrical in the axial projection plane, and the airflow path Wav...

Embodiment 3

[0056] Such as Figure 7 As shown, an internal combustion engine exhaust muffler for motorcycles includes a cylindrical cavity 5 surrounded by a muffler 3 housing 31, a muffler 3 inlet, and a muffler 3 outlet 32, and a muffler unit is arranged in the cavity 5. The noise reduction unit includes a partition 1 and a spiral structure 2 .

[0057] The partition 1 is a spiral plate coiled axially along the cavity 5, and the width direction of the partition 1 is consistent with the radial direction of the cavity 5 and is smaller than the radius of the cavity 5; 12 is fixed on the housing 31; from the inlet to the outlet 32, the width of the partition 1 increases gradually, and the inner edge 13 of the partition 1 in the width direction is conical and spiral; between the adjacent circles of the partition 1 along the cavity 5 axial direction The gap between the gaps constitutes the helical air channel 11 that communicates with the cavities 5 at both axial ends of the partition plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com