Membrane type hydrostatic pressure sensor

A hydrostatic pressure and sensor technology, applied in the direction of fluid pressure measurement involving the displacement of the magnet, can solve the problems of affecting the flow state of the water, not adapting to the underwater test environment, low test accuracy, etc., achieving easy automatic control, light weight, high resolution good rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

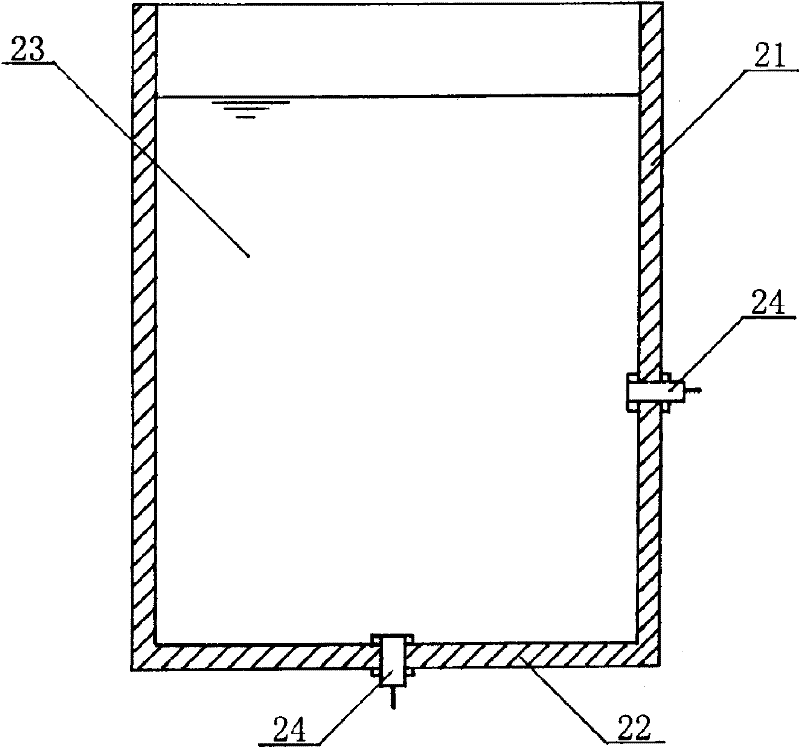

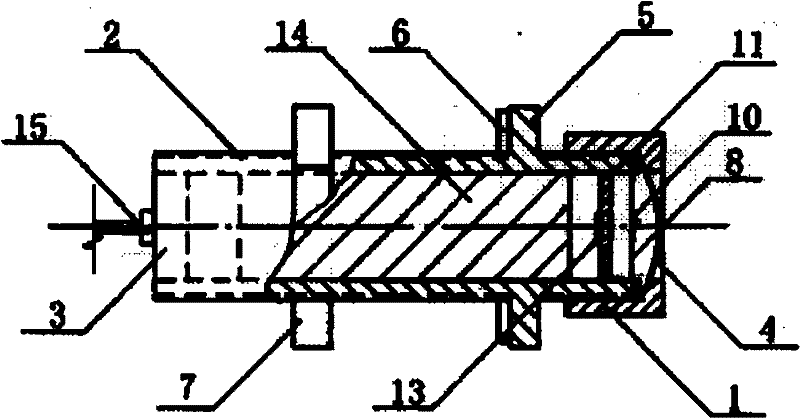

[0028] see Figure 2A , Figure 2B with Figure 2C , the structural form of the membrane hydrostatic pressure sensor 24 in the present embodiment is:

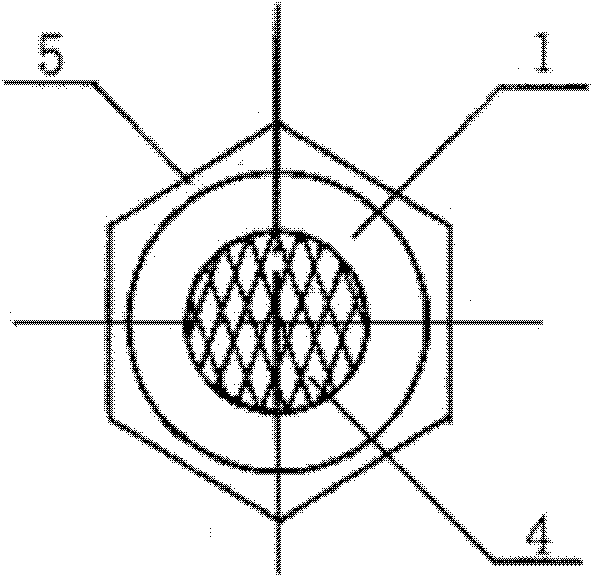

[0029] The machine cap 1, the fuselage 2 and the bottom cover 3 are located on the same central axis, and are screwed together to form a cylindrical body; wherein, the machine cap 1 is in the shape of a round cap, has an internal thread structure, and has a through hole on the top; The outer periphery of 2 is located in the middle section and is provided with a hexagonal shoulder 5, so that the sensor 24 is installed, the two ends of the fuselage 2 are set as external thread segments, and the outer periphery of the fuselage 2 near the end where the cap 1 is located is provided with a water-stop rubber ring. 6 and a nut 7 for fixing the sensor 24.

[0030] The cylinder is divided into two chambers in the axial direction by the elastic membrane 8 arranged on the cross-section of the fuselage, one is a pressure chamber communic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com