Method for measuring Young modulus through Doppler vibrating mirror sinusoidal modulation of multi-beam laser heterodyne second harmonic

A technology of Doppler galvanometer and laser heterodyne, which is applied in the direction of measuring device, using optical device, and applying stable tension/pressure to test the strength of materials, etc. It can solve the problems of laser difference frequency signal and signal processing operation speed, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

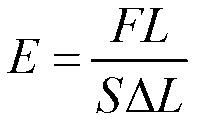

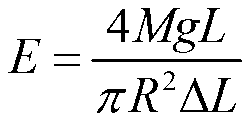

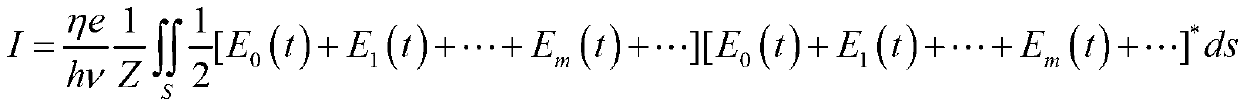

[0063] Embodiment 1: Combining figure 1 This embodiment is described. The method for measuring Young's modulus by the second harmonic of the Doppler galvanometer sinusoidally modulated multi-beam laser heterodyne described in this embodiment is based on the Doppler galvanometer sinusoidally modulated multi-beam laser heterodyne two It is realized by a device for measuring Young's modulus by subharmonics, which includes a device for measuring distance with multi-beam laser heterodyne, which consists of a H0 solid-state laser 1, a flat mirror 6, a quarter-wave plate 3, and a galvanometer 2 , galvanometer driving power supply, polarizing beam splitter 4, converging lens 9, thin glass plate 5, photodetector 10 and signal processing system. The galvanometer driving power supply is used to drive the galvanometer mirror 2 to vibrate; the thin glass plate 5 is horizontally fixed, A flat mirror 6 is arranged at a distance d directly above the thin glass plate 5, the thin glass plate 5 ...

specific Embodiment approach 2

[0120] Embodiment 2: This embodiment is different from Embodiment 1 in that xMg is within the elastic limit of the metal wire to be tested. Other compositions and connection methods are the same as those in the first embodiment.

specific Embodiment approach 3

[0121] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the metal wire 8 to be tested is a steel wire. Other compositions and connection methods are the same as those in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| angle of incidence | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com