Device and method for multi-component online polargrafic detection of metallurgical feed liquid

A detection device, material liquid technology, applied in the direction of material electrochemical variables, etc., can solve the problem that the speed control of the mercury storage bottle, the highly accurate control of equipment efficiency, and the screw motor cannot meet the requirements of rapid lifting, rapid measurement, and upper and lower limits. The switch cannot realize automatic adjustment and other problems, so as to improve the service life, ensure the quality of production, and improve the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings.

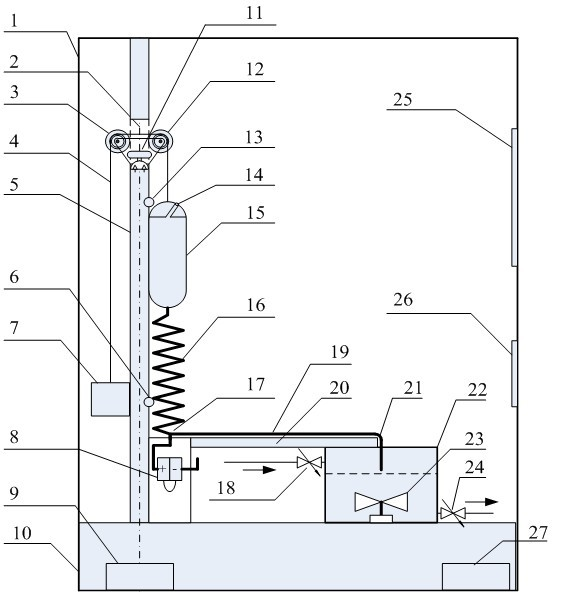

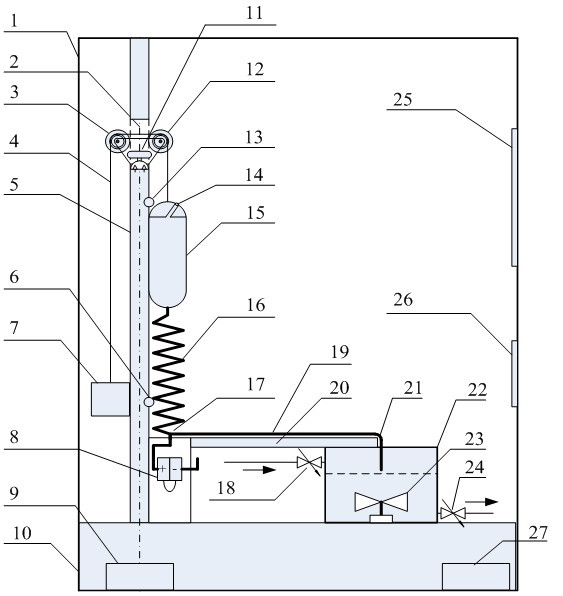

[0042] Such as figure 1 , the device of the present invention is a cuboid, with three cavities in total, two cavities, a front cavity and a rear cavity, and a cavity below, which are used to place a fixed lifting / lowering speed optimization control unit 9 and a signal processing and driving unit 27 . There is an intermediate wall hole 2 between the front and rear two cavities, and the steel wire cable 4 passes through the intermediate wall hole 2. The intermediate wall holes 2 are respectively located in the front cavity and the rear cavity of the instrument cabinet, and the servo motor, the runner 12, the guide wheel and the grating 3 are fixed on the intermediate wall layer through a triangular bracket. The slideways of mercury storage bottle 15 and balance counterweight device 7 are respectively designed before and after the middle wall layer, and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com