Dynamometric electric servo loading device

A technology of electric servo and loading device, which is applied in the direction of testing wear resistance, circuit breaker testing, etc. It can solve the problems of inability to control cylinder stroke and loading force, inability to complete high-intensity fatigue tests, and inability to perform real-time control, etc., to achieve The effect of omitting the deceleration mechanism, reliable structure and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in detail below in conjunction with accompanying drawing:

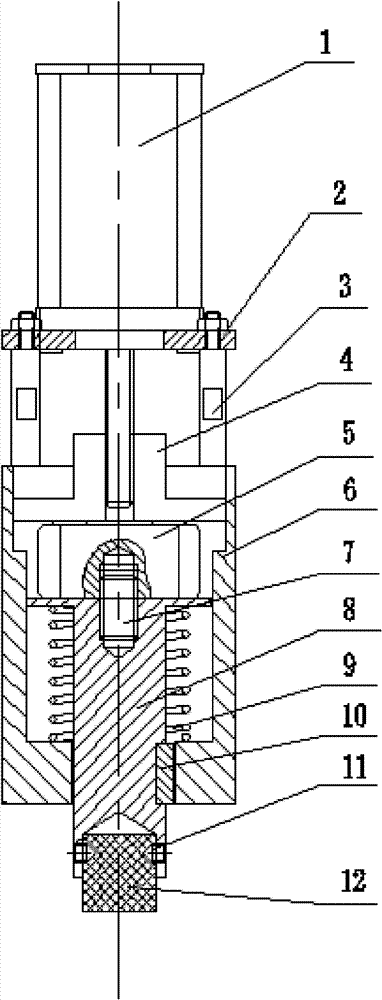

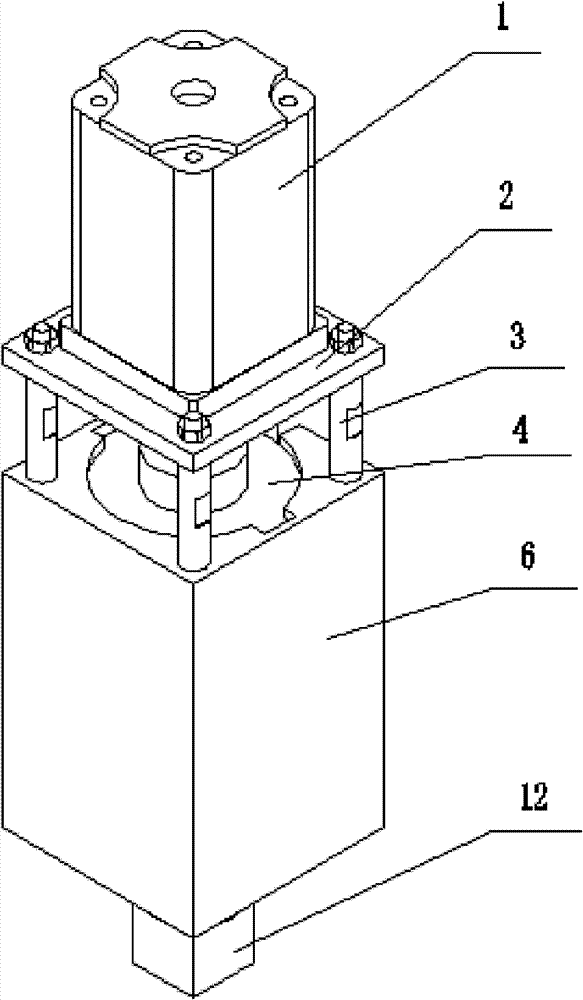

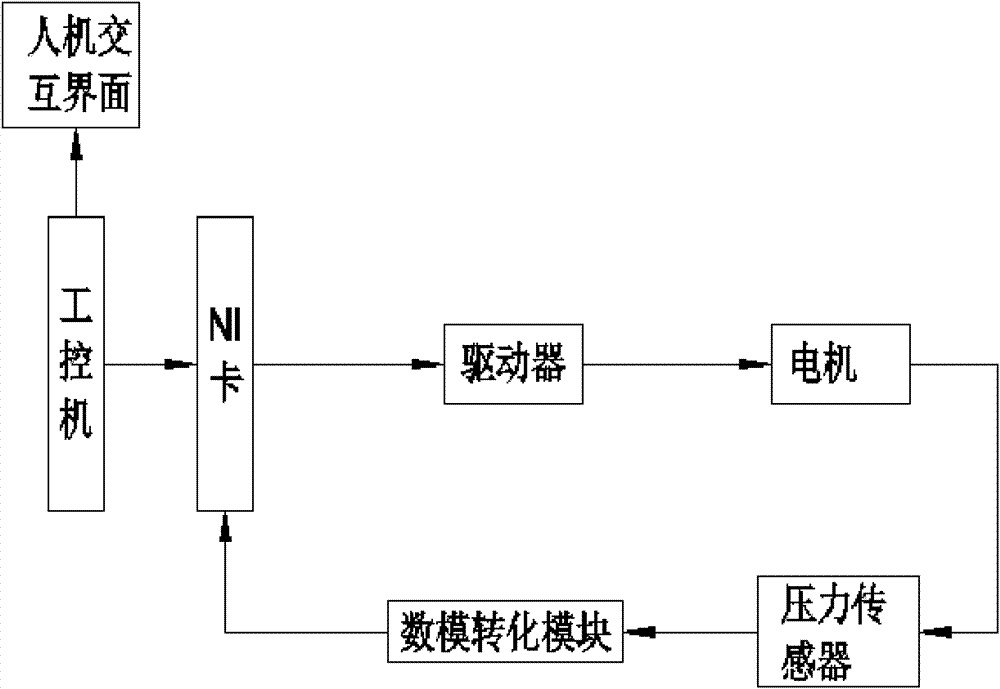

[0028] refer to figure 1 and figure 2 , The force-measurable electric servo loading device of the present invention consists of a mechanical part and an electric control part. The mechanical part includes a hybrid linear stepping motor 1, a motor base 2, 4 motor support columns 3 with the same structure, a screw nut 4, a pressure sensor 5, a casing 6, a connecting stud 7, an actuating rod 8, a Standard pressure spring 9, guide key 10, clamping screw 11 and elastic contact 12.

[0029] The entire force-measurable electric servo loading device has a compact and stable structure, and the overall structure is made of aluminum alloy, which makes the force-measurable electric servo loading device more portable, and can be installed in various test equipment in a single piece or in batches.

[0030] The output end of the hybrid linear stepping motor 1 is directly provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com